Hello fans to master, in this instruction we will discuss how do it yourself make a powerful stove out of gas cylinders. On such a furnace you can not only cook, but even melt aluminum. The type of furnace manufactured is rocket, that is, the furnace is isolated here, due to which a high combustion temperature is achieved. In addition, you can connect a household hair dryer or other device for boosting air to the stove, as a result, the stove starts working like a jet turbine, the wood burns at a very high temperature, with such a stove you can forge and even cast non-ferrous metals. If you are interested in the project and you need such an oven, I propose to study the project in more detail!

Materials and tools used by the author:

Material List:

- two gas cylinders (small and large);

- a piece of iron pipe or the body of a fire extinguisher;

- sheet stainless steel with a thickness of at least 4 mm;

- round timber;

- paint.

Tool List:

- pipe bending and bending machine;

- ;

- drilling machine;

- ;

- vise;

- belt sander;

- jigsaw;

- ;

- tape measure, marker.

Furnace manufacturing process:

Step one. We disassemble the cylinders and cut

When working with gas cylinders from under flammable gas, be extremely careful, because even if you wash such a cylinder, there is a high probability of it exploding when cutting. The most reliable option is to pour water into a cylinder and cut it with a cylinder filled with water, then there will simply be nothing to explode. But here you need to be careful not to wet the grinder with water, since you can also get an electric shock.

From the large gas cylinder cut off the bottom and cut off the stand. This part will be used as a basis. And in order not to spoil the cylinder, you can use just a thick iron sheet or weld a base from corners, profile pipes, etc.

We also need a large fire extinguisher, unwind it, pour out the contents and cut off the bottom and neck of the cylinder. Or you can simply use a piece of pipe of a suitable diameter. This will be the oven rack that will connect the upper and lower parts. In addition, this pipe will work like a blower, through it we can supply air with a hairdryer forcibly.

And at the end we cut a small gas cylinder, from it the outer case of the furnace is assembled, as well as the lower part of the furnace.In the cut off upper part of the cylinder we cut out the core, the author of the work is a jigsaw. The hole should be the diameter of the rack.

Step Two Weld the base

Getting to welding, all parts must be well cleaned from paint, which will burn when heated. Then the oven will be painted with heat-resistant paint. You can start welding, weld the stand (fire extinguisher body) to the base and drill a hole in the bottom with a crown. We weld a piece of pipe into the hole, we will insert a hair dryer into this pipe, and even here we can install a damper to adjust the amount of air.

As for the top of the rack, here we weld the "bowl", which we cut from the top of the small gas bottle.

Step Three Grate

We make grid-irons for the furnace, here you need thick sheet steel. Since the combustion temperature will be very high, stainless steel is well suited, it is resistant to burning. The author has a steel thickness of 4 mm. We cut out a circle and drill holes, in the center it’s bigger and smaller along the edges. That's all, now the grate can be welded to the "bowl".

Step Four Combustion chamber

You can make a combustion chamber, here you will need either a thick-walled pipe of suitable diameter or stainless steel sheet like the author’s. To bend sheet steel into a pipe, we need a bending machine. Having made the pipe, we weld it to the grate. Part of the grate will be open, will be located outside the firebox. These holes are needed for ventilation, so that the furnace does not overheat and does not burn out.

As a result, for the combustion chamber we need to make a narrow neck, here again we need a sheet of stainless steel. We cut, rot and cook.

Step Five The outside of the furnace

We weld the outer part of the furnace around the furnace, as a result, we get a chamber inside, which will allow the furnace to warm up to high temperatures. As a material, we use a previously cut small gas cylinder, just weld it into place.

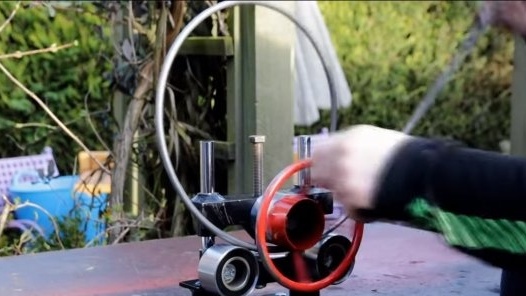

Step Six Dish Stand

In conclusion, it remains to make a stand on which we will place the dishes. First you need to cut out 6 identical in shape and size sheet metal parts. To make the details the same, the author welds them, and then grinds everything together on a tape machine. In detail, drill holes for the ring. The ring itself is made of iron round timber, we bend it on a pipe bending machine. That's all, now the stand is left to cook on the stove.

Seventh step. Painting and testing

We will color the furnace, otherwise it will oxidize with rhinestones and will quickly collapse under the influence of temperature and oxygen. For painting, you need heat-resistant paint.

That's all, now the furnace is ready for testing, throw chips into the furnace and kindle. And in order for the stove to flare up quickly, you can force the air with a hairdryer. It is quite convenient to quickly cook on the stove, and if you set the damper on the blower, you can quite accurately control the temperature.

The author also demonstrates the capabilities of the furnace, trying to melt aluminum in it. The crucible is heated red-hot and aluminum melts without problems.

Homemade can be considered successfully completed on this, I hope the project was useful to you, and you found interesting thoughts for yourself. Good luck and creative inspiration, do not forget to share your ideas and homemade things with us!