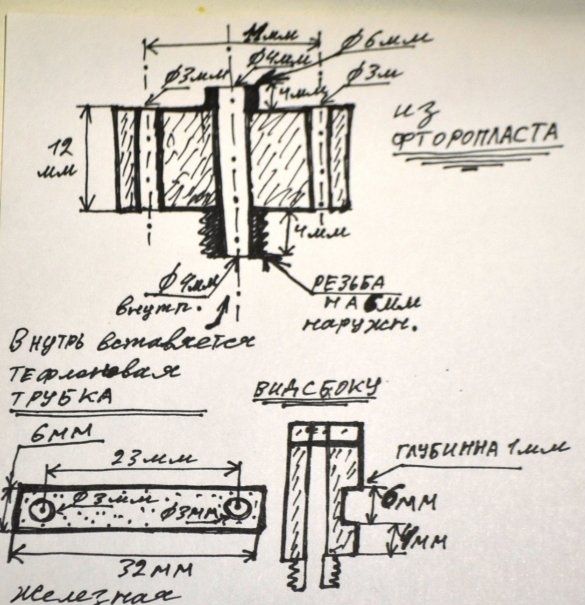

And so we need. The first is a fluoroplastic bar 20x20x10 mm. The second or two strips of fluoroplastic 20x70x5 mm. Third - aluminum block 15x16x9 mm. Fourth - a metal corner 1 mm thick and 35 mm long, 17 mm high, 10 mm wide. The fifth aluminum radiator 45x22x10, you can take any suitable one, I took it from a broken computer power supply. Sixth - a Teflon tube with an external diameter of 4 mm, an internal 2 mm and a length of approximately 30 mm, I will explain that the Teflon tube will need to be closely adjusted in place. Sixth iron plate 32x6x1 mm. And, accordingly, 3mm sweat screws, nuts, a ceramic heating element 12V 40W, respectively, thermal resistance 100kOhm.

Note that PTFE is very well cut with a sharp knife. But sandpaper is not very amenable to processing.

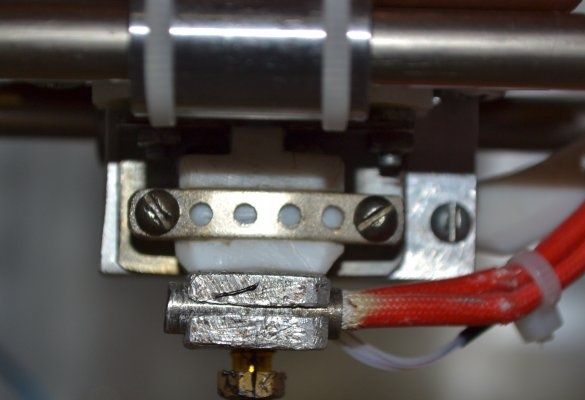

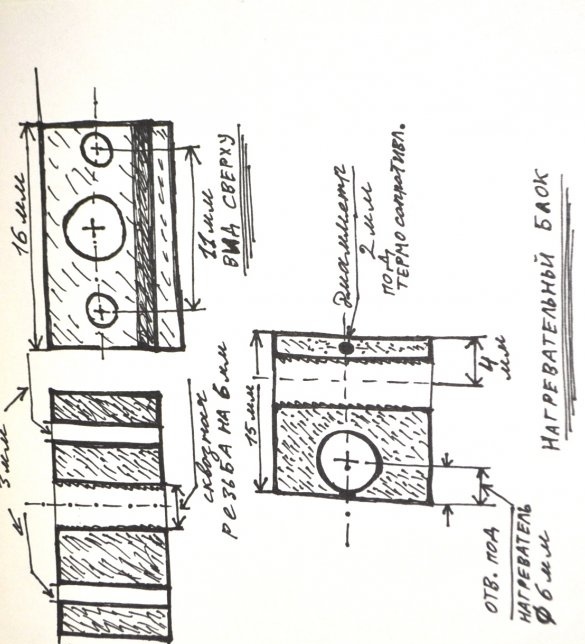

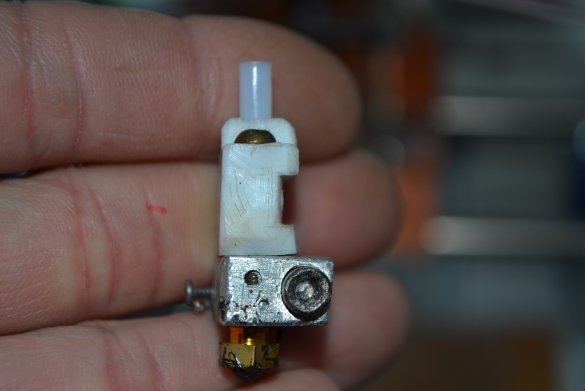

First, we make a heating block, drill holes according to the size indicated in the figure.

Now we make such a block according to the dimensions indicated on the drawings from PTFE. The main thing is not to rush, so as not to spoil the bar.

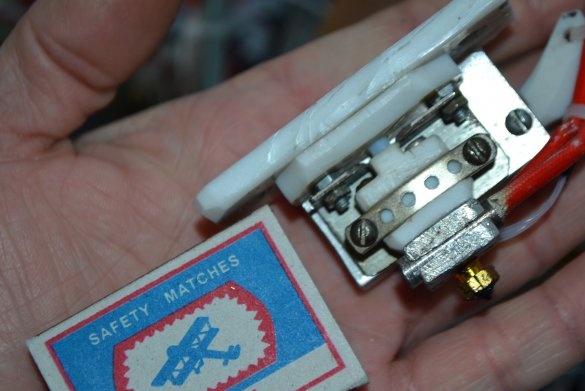

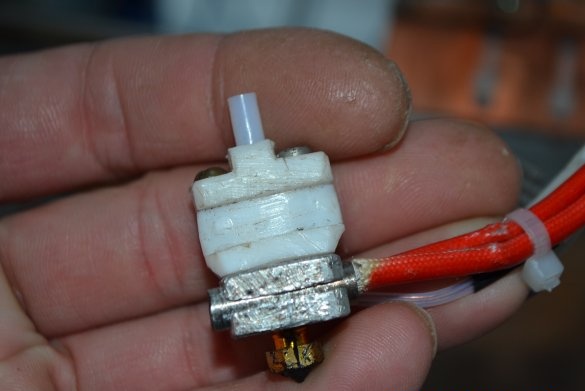

Now we connect the heating block and the fluoroplastic block, pay attention to the fact that it would be enough to wrap the nozzle in the heating block.

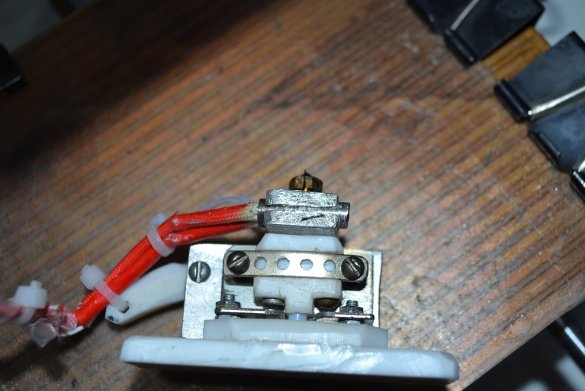

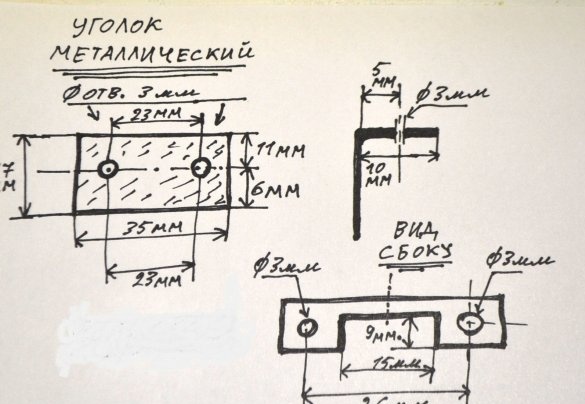

We make a corner as in the drawings.

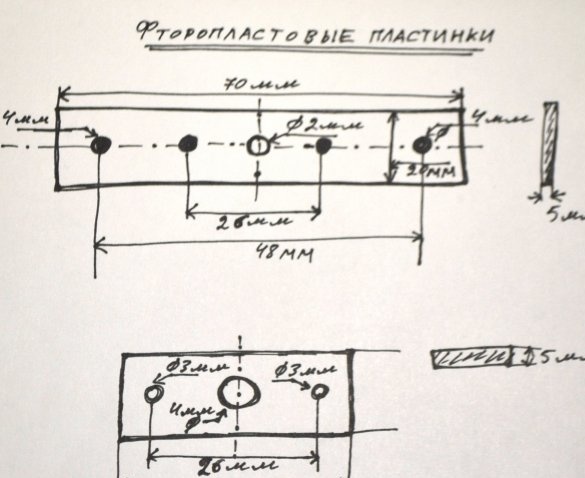

Cut two plates of fluoroplastic as in the drawings.

I have such a radiator. You can take any suitable one, the main thing is that it fits in size.

Mounting plate.

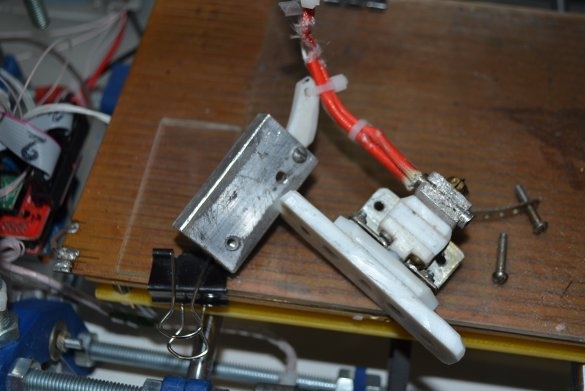

We connect and try everything.