In this article, we will consider the manufacture of a hydraulic press with a force of up to 6 tons. The dimensions of the press are 750x470x320 mm.

The main frame with a reinforced structure can work with a 6-ton jack mounted on the upper side of the frame without bending or breaking the frame. If you plan to use a jack of 3 tons or lower, then the upper part can not be reinforced with reinforcement.

Tools and materials:

-Angle grinder;

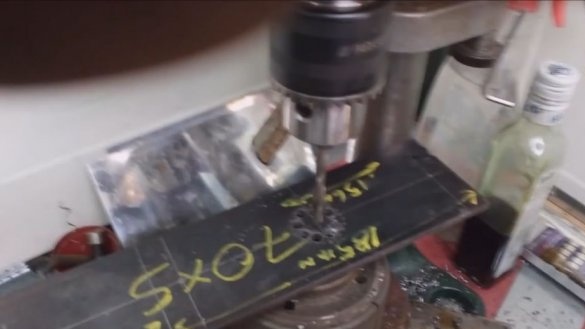

-Drilling machine;

-Drill;

Countersinks

-Punch;

-Set of taps;

-Welding machine;

-Welding magnetic angles;

-Roulette;

-Calipers;

-Punch;

-Vise;

- clamps;

-Spanners;

- Hexagons;

-Screwdriver;

-Hammer;

-Steel blanks of different sizes and shapes;

-Metallic profile;

-Metal Corner:

-Sheet metal;

-Metal square;

- A metal core from stainless steel;

-Fittings;

-Fasteners;

- fitting;

-Plastic tube;

-Plastic bottle;

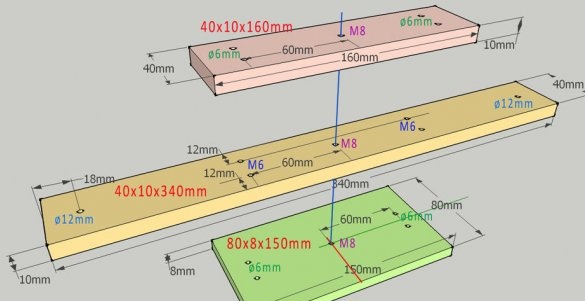

Step One: Drawings

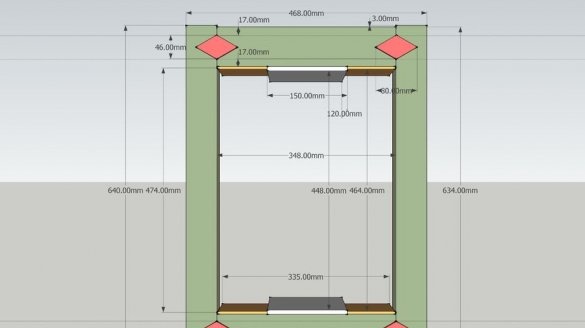

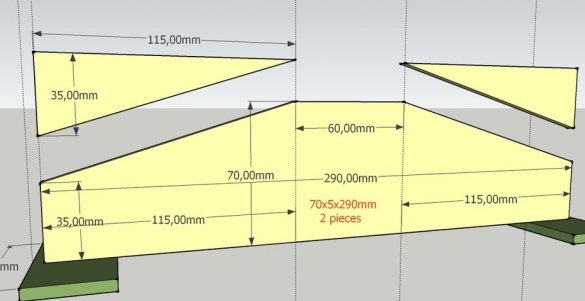

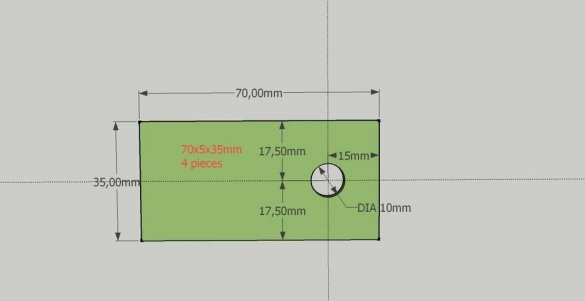

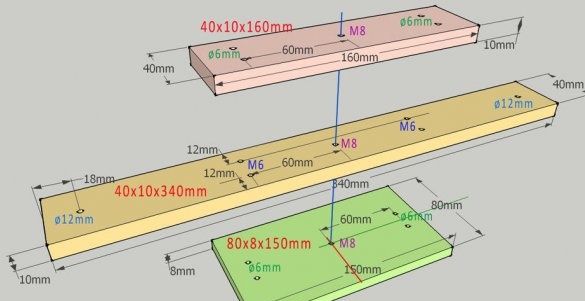

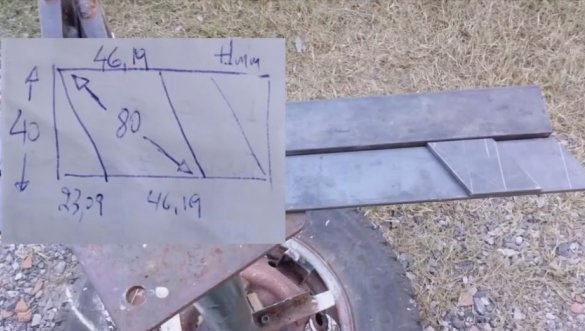

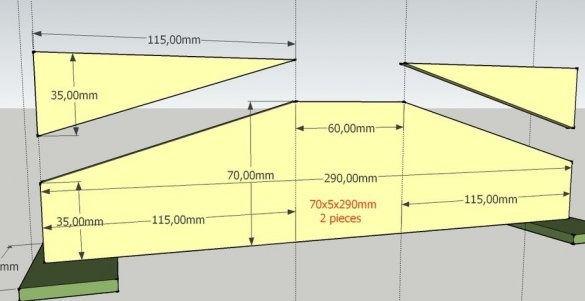

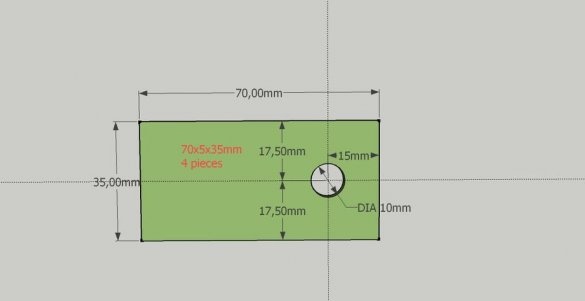

Before starting work, the master made a project and drew drawings of each node.

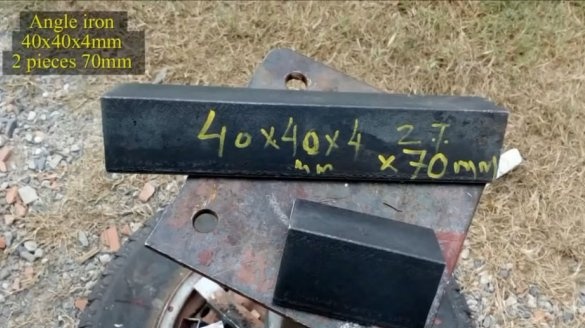

Step Two: Frame

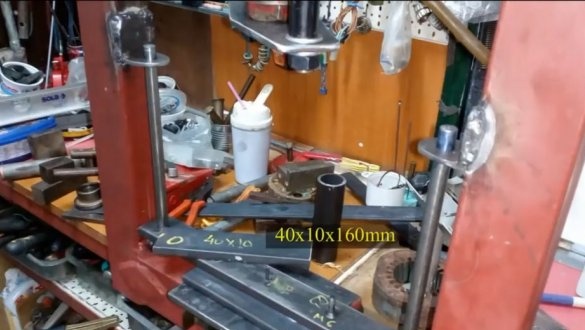

According to the drawings, it procures material for the assembly of the frame.

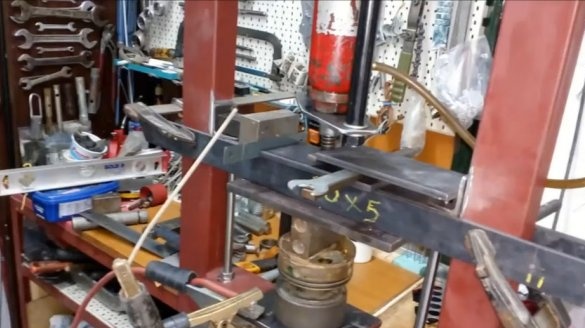

Welds the press frame.

Strengthens the design by welding metal plates of thick metal to the internal shelves of the profile. Welds the pads to the corners of the frame.

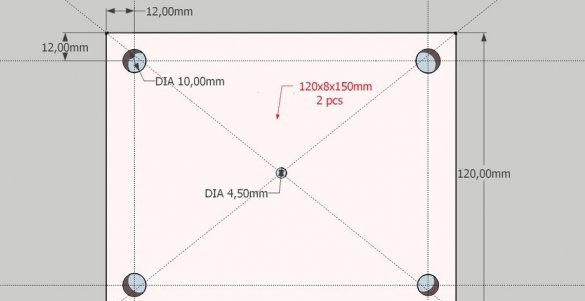

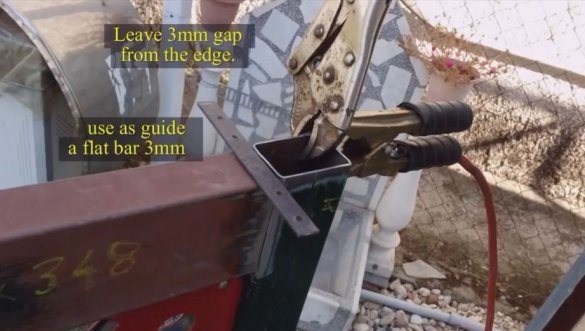

Marks the center of the top frame profile. Drills a hole in the center. Cut the base plate. A hole is drilled in the center of the plate. Drills a hole in the corners and cuts the thread. Welds the base plate to the frame. The lower base plate differs from the upper, only the absence of threaded holes.

In the upper outer part of the frame, reinforcement is welded to reinforce. The central rod is inserted into the hole in the pipe until it stops and is welded from the outside. Two pieces of reinforcement are welded diagonally.

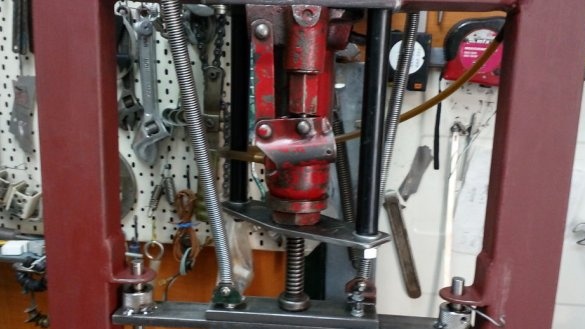

Step Two: Hydraulic Jack

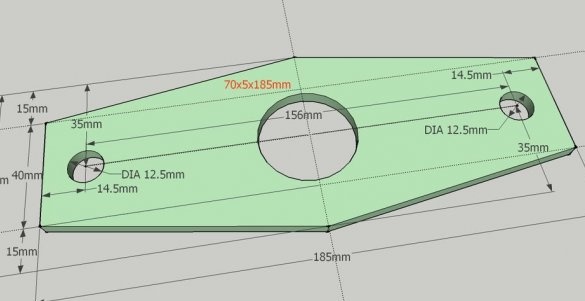

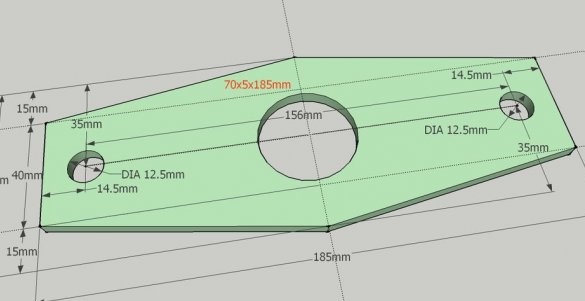

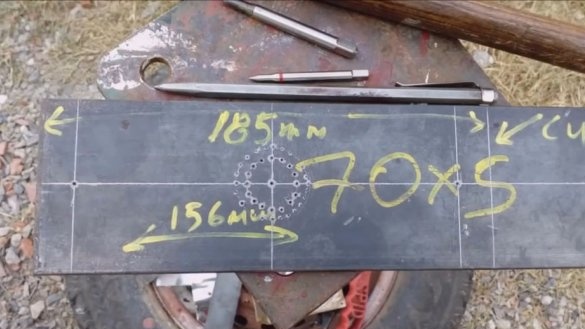

To install the jack, the master makes a mounting plate with a diamond shape. In the center of the rhombus, drills a hole for the jack rod, along the opposite edges of the hole for the mounting bolts.

Further, the master remakes two jacks, 2 and 3 tons, for their work upside down.

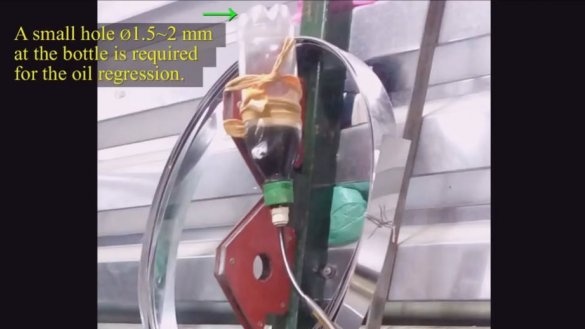

In the 3-ton jack below was an oil plug. The master screwed the fitting in its place. He puts the pipe on the fitting. The other end of the tube is fixed in a plastic bottle. Pour oil into a bottle and hang it at the top of the press.

There was no hole in the second jack, and the master dismantled it, drilled a hole and installed a fitting.

Step Three: Supports

According to the drawing, makes and welds to the frame of the support. The support plates have holes for mounting the press.

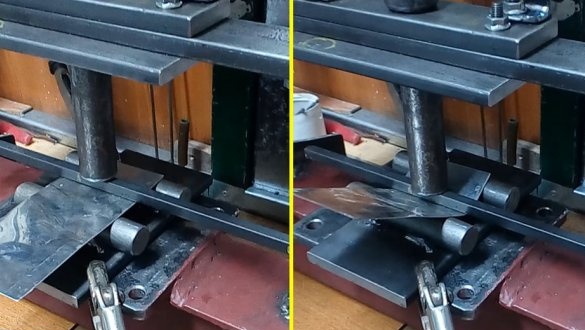

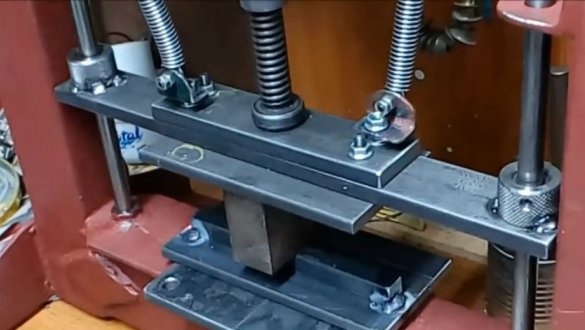

Step Four: Sliding Plate

Now you need to make a platform on which the rod of the jack will press. This platform should be movable and mounted on rails.

Aligns the jack exactly in the center of the lower base plate.

According to the drawing, it makes parts of the moving part of the jack from metal plates.

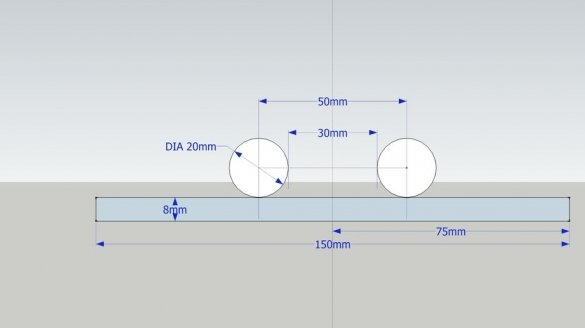

The guides are made of a metal rod. One end of the rod is welded to the bottom of the frame, the second is installed in the corner welded to the frame and the hole in the plate.

At the top of the guide, drills a hole and sets a cotter pin.

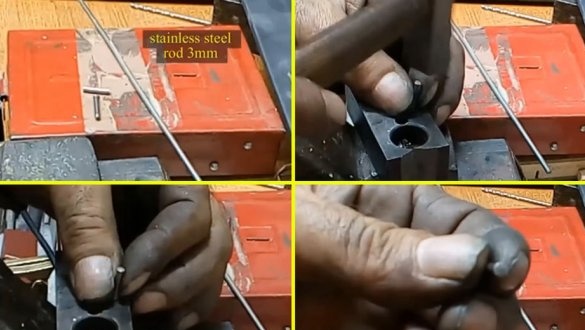

For immobility of the plates during drilling, the master uses a metal cotter pin. He drills the first hole and sets the cotter pin, then the second one, and also fixes it with a cotter pin.

The moving part is assembled from three plates. In the middle is a long plate with holes for guides. In the holes of this plate, the master cuts the thread. Screws the bottom plate to the middle. The upper plate is mounted on the protruding parts of the screws and secured with nuts. Cuts a thread in the center of the bottom plate in the hole.

Along the edges of a long plate welds bushes for guides. Screws two corners. The ends of the springs will be fixed in the eyes of the corners, which will pull the plate up.

Step Five: Bending Dies

The press is ready and the master makes several bending dies.

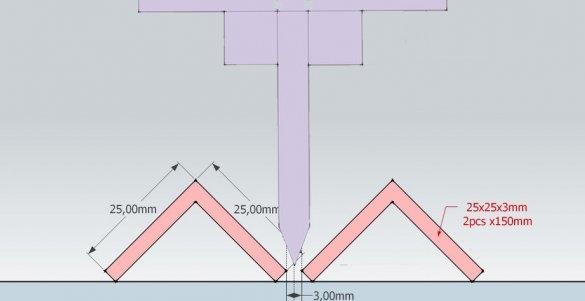

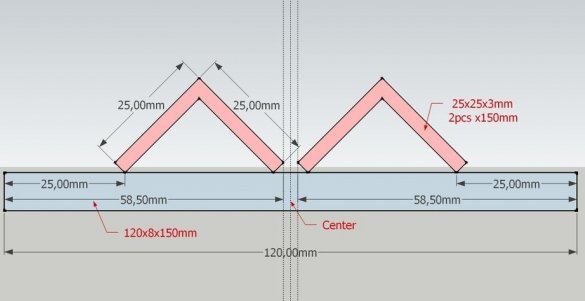

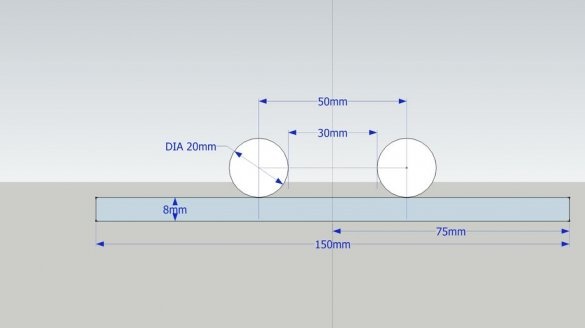

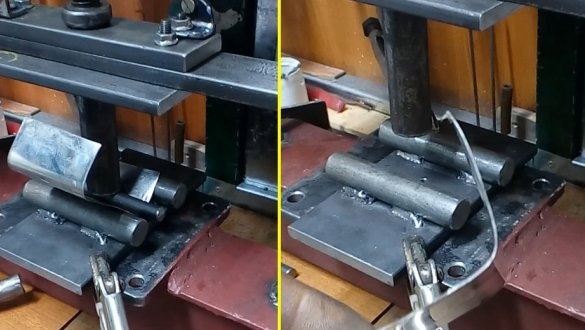

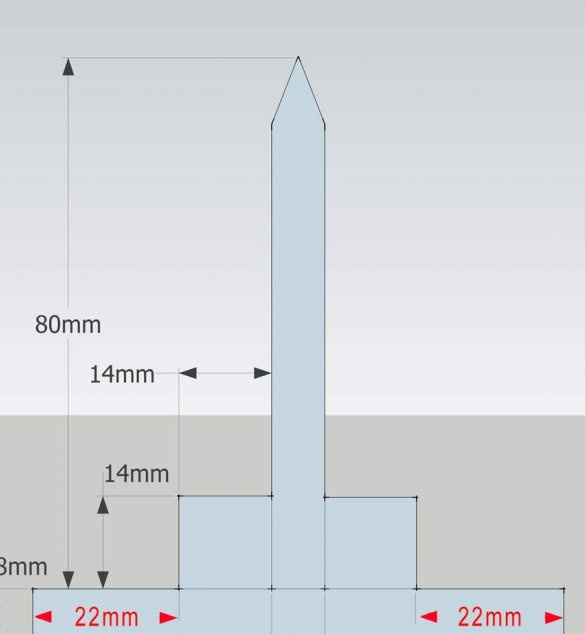

Stamp number 1.

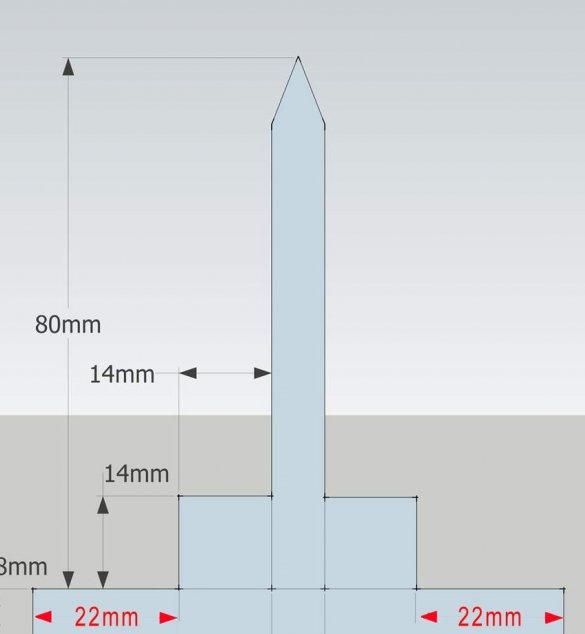

This stamp is suitable for bending flat, square rods, rods and sheet metal. The upper part of the stamp is made of a metal rod. A hole is drilled in the center of the rod. A thread is cut in the hole and a stud is screwed in. Then the stamp is screwed into the hole in the press plate.

The lower part is made of two metal rods welded to the plate. The plate has a mounting plate and is fixed to the bottom plate with a bolt.

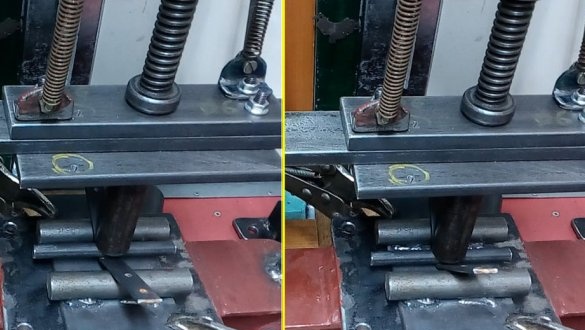

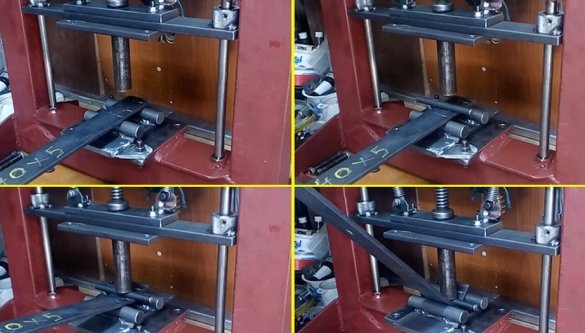

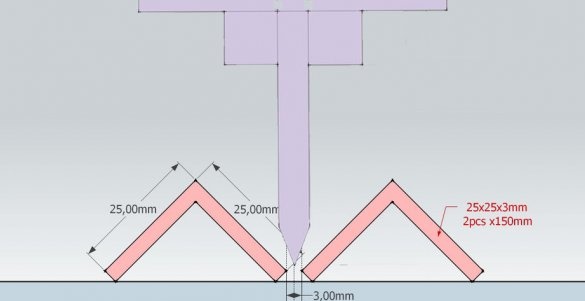

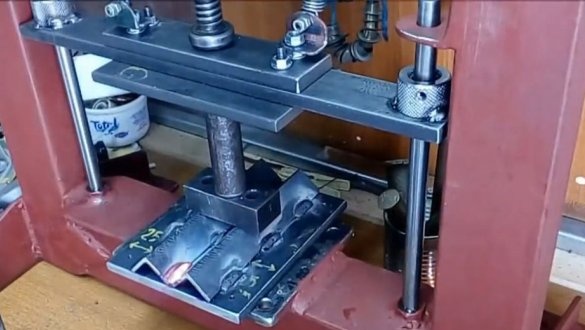

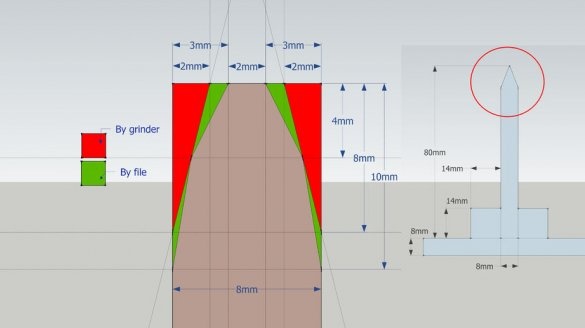

Stamp number 2.

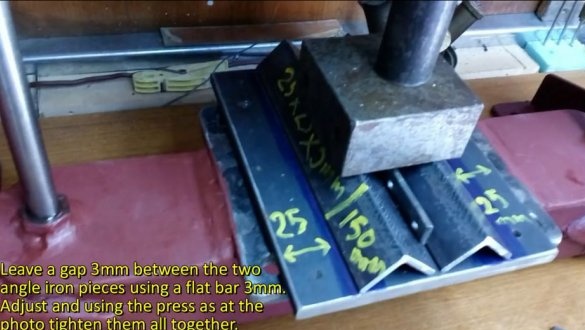

The lower part of such a stamp is made of two parallel corners welded to the plate. The plate also has a mounting hole and is screwed to the bottom plate.

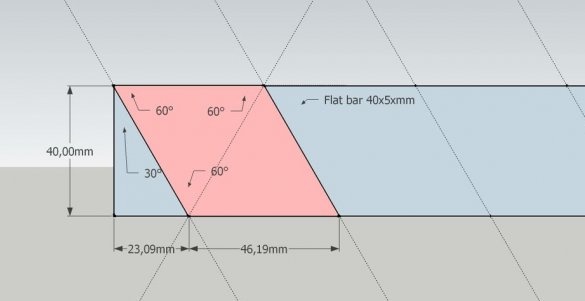

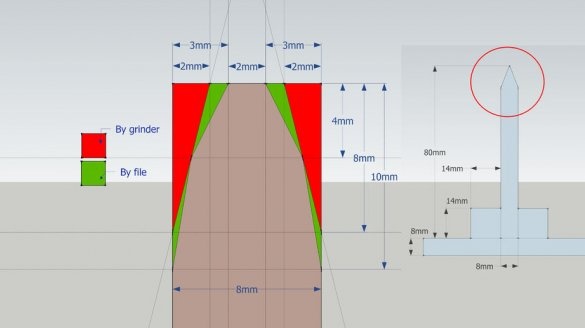

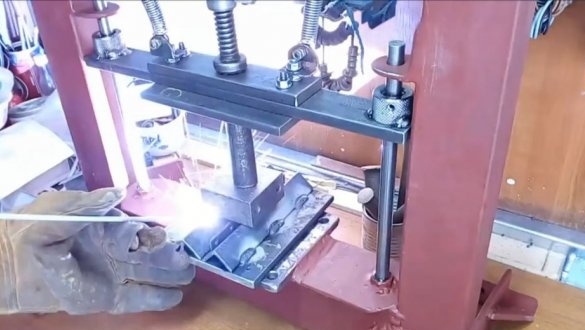

The upper part is made of a plate with an end portion sharpened at an angle. The plate is welded to the other plate perpendicularly and fixed to the movable plate.

After making the stamp, its working part is sharpened.

The hydraulic press with dies is ready. The master did a great job with an excellent result.