Let's get back to the topic of homemade items from old car parts. They are very affordable, and in the presence of imagination very interesting products are obtained.

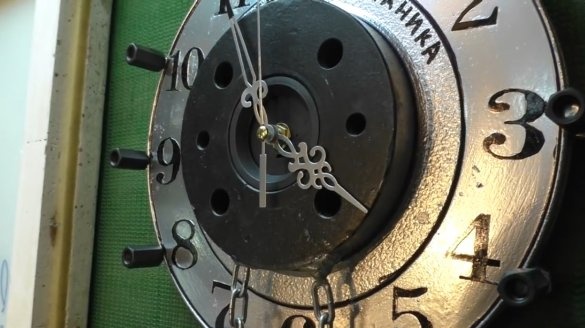

In this article, the author of the YouTube channel "Glavnyiy Mehanik" will tell you how he made a watch from an old automobile brake disc. They turned out in the "garage" style.

Materials

- Brake disc

- Steel chrome chain

- Elastic

- Two old car spark plugs

- Silver and black spray paint

- Cheap chinese watches

- 12 extended nuts and bolts M4

- Degreaser, second glue.

Instruments, used by the author.

-, cleaning disc

-

-

- Pliers, a vice, scissors, a screwdriver.

Manufacturing process.

The author just recently replaced the brake discs on the Prior. And from it he will make the foundation of the watch. To begin with, he cleans the surface of the workpiece from rust with a grinder with a metal brush.

Then necessarily degrease the surface before painting with solvent.

Now applies silver spray paint in two layers.

The next step is to choose a clock mechanism. It can be purchased on Aliexpress. But the author did not bother, and took the movement with arrows and dial from a cheap Chinese wall clock.

Unscrewing the nut, he pulled the mechanism out of the case.

Then he took out a dial, cut a hole in it in the center, and attached it to the workpiece. So he will definitely be able to mark the places where the bolts should be welded. Each of them will correspond to an hour mark.

The marking is applied, and the author welds all 12 bolts around the perimeter.

To hang the watch, the master will use such a hook, and weld it to the top of the watch.

The author also purchased just such a chain, and will weld it to the bottom of the ledge of the disk. Two old spark plugs will be suspended at its ends. Thus, an imitation of antique watches with weights will be created.

Then the master puts on 12 elongated nuts on the wire, and paints them black.

It covers the perimeter of the dial with paper, and paints the central part.

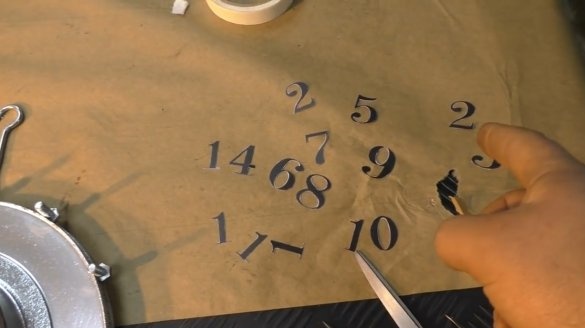

And so that the paper dial does not disappear, the author cut out all the numbers, and glued them into place with second glue.

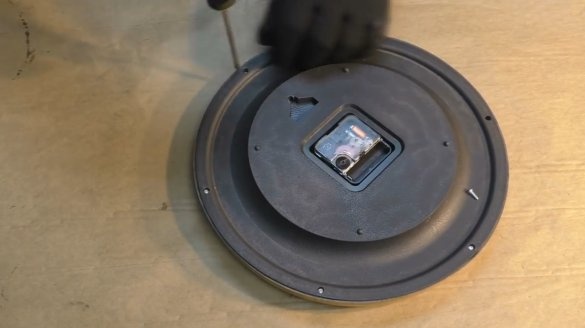

Now he needs to fix the mechanism on the back of the disk. There will be no loads on it, and it can be glued at four corners with hot melt adhesive.

In order to close the holes between the mechanism and the case, the author inserted a black rubber band from a 50 mm plumbing pipe there. She didn’t even have to stick, she went so well.

Screws painted nuts onto bolts.

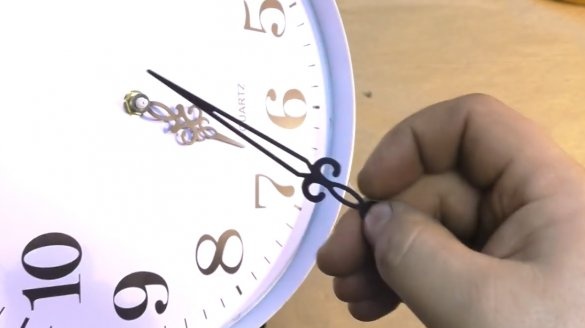

Before installing the arrows, he also painted them. First, completely silver paint, and the tips - black.

All arrows are set to position 12-00-00.

This is how the mechanism glued to the back of the case looks. It remains to install the battery.

Indeed, without weights, the clock would not have looked completely completed. Now you can throw away the Chinese plastic case, because the author has real steel watches in the garage style!

Thanks to the author for a simple and interesting design idea for remaking watches!

All good mood, good luck, and interesting ideas!

Author video can be found here.