Hello everyone, if you have a drum from a washing machine, don’t rush to throw it away, you can make an excellent street out of it. Such a drum is made of stainless steel, so that it can withstand high temperatures, as well as frequent heating and cooling. In addition, there are many openings in the drum, thanks to which air perfectly passes into the furnace. The author made a hearth in a concrete case, this increases the safety of the structure, reduces the amount of garbage, and everything looks quite interesting. Going to homemade quite simply, if you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- a drum from a washing machine;

- heat resistant concrete;

- fiberglass;

- iron grate (for reinforcement);

- fiberboard;

- boards;

- self-tapping screws;

- silicone sealant;

- heat resistant paint;

- grill grill (optional).

Tool List:

- mixer for mixing concrete;

- grinder;

- screwdriver;

- milling cutter.

Homemade manufacturing process:

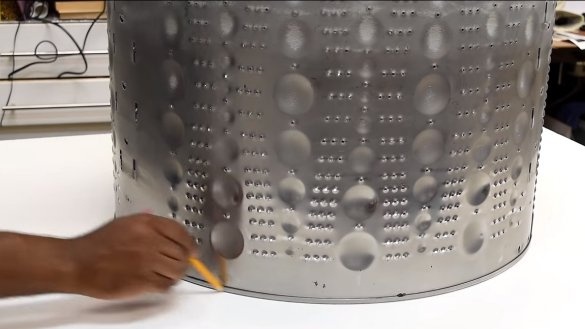

Step one. Drum preparation

First of all, we need to prepare the drum, we need to remove from it the plastic blades and other details that may be in it. The design of the drums of all machines is different, and the sizes of the drums are different. As for the axis, it can be cut off with a grinder.

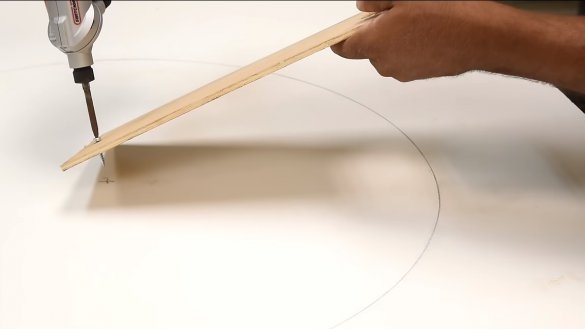

Step Two Formwork

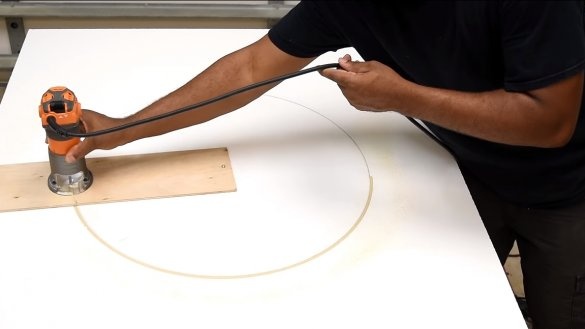

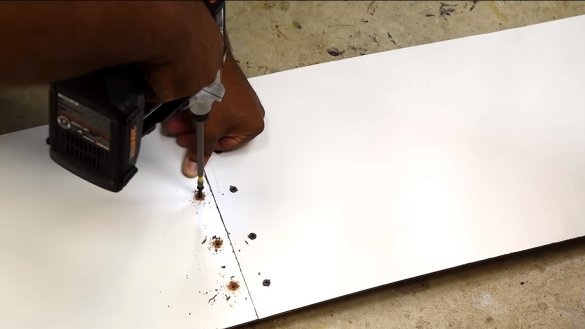

Next, we need to make the formwork, into which we will pour concrete. As a basis for formwork we use chipboard or other similar durable material. Cut off the desired piece with a hand circular saw.

As the side walls we will use fiberboard, it is important to ensure a good joining of materials for tightness and strength. To solve the problem, the author arms himself with a manual milling cutter and makes the basis of the grooves into which the fiberboard will go.

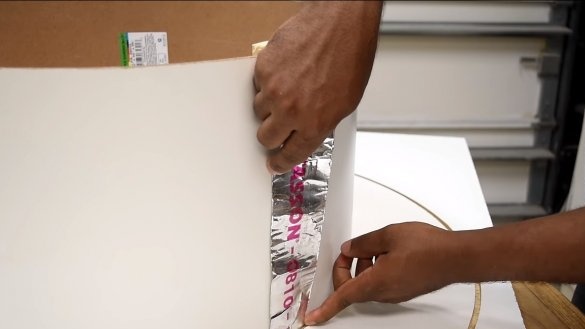

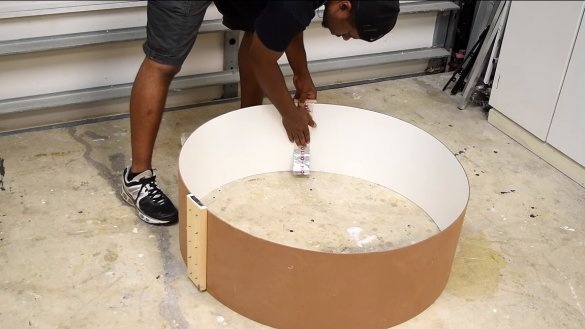

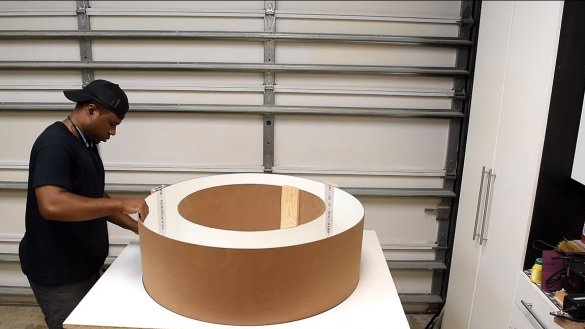

Well, then from the fiberboard you need to collect two rings, which will be the walls of the formwork. We fasten the ends with the help of pieces of boards and screws.Of course, in these places it is important to ensure tightness. Glue the joints with a good duct tape. Rings need to be strengthened so that they do not fall apart under the weight of concrete. We strengthen the walls with boards, screwing them to the base.

The final touch will be the tightness of the joints. For such purposes we use silicone sealant. That's all, now the formwork is ready!

Step Three Grouting

You can fill the formwork solution, if you are not sure about the strength of the formwork, it is better to fill the solution in parts, waiting for it to set. It is necessary to add fiberglass or other binding elements to the solution, as a result, the structure will not crack, and if it gives a crack, it will not break. The solution should be made of heat-resistant concrete, in extreme cases, furnace clay can be used.

To further strengthen the structure, the author reinforced it with an iron mesh. Thanks to the mesh, the concrete rim will not fall apart, even if it is broken. That's all, now we leave this whole thing to dry.

In the meantime, you can paint the drum black, you will need heat-resistant paint. To paint reliably, it is recommended to grind the surface with a grinder with a petal nozzle.

Step Four Installation

It remains to install the furnace, at the installation site we dig a hole along the diameter of the concrete rim and install it. Stones and heat-resistant bricks can be laid at the bottom of the pit so that the bottom of the drum does not overheat, and so that the drum does not warp.

That's all, now it only remains to install the drum and the furnace can be tested. The hearth turned out to be excellent, the fire burns beautifully. The author also tried to install a grate on the hearth and donate corn.

On this our review of the project is over, I hope you liked the homemade product. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!