Hello to all fans of craftsmen, today we will consider how to make a simple and trouble-free machine for bending pipes. Such a machine will be very useful if you are engaged in the manufacture of various metal structures. The main difficulty in manufacturing the machine is the presence of a lathe, it is needed for the manufacture of axles. As for the pressure unit, its author made of an ordinary building threaded rod and two elongated nuts. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- old automobile or similar axles;

- automobile bearings;

- threaded rod and two elongated nuts;

- round pipe (for the manufacture of bearing races);

- channel;

- thick sheet steel;

- corner;

- paint (and patina optional).

Tool List:

- lathe;

- drilling machine;

- grinder;

- welding machine;

- marker, tape measure, etc.

Manufacturing process homemade:

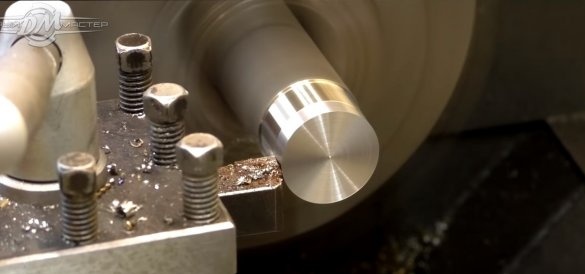

Step one. Turning works

First, using a lathe, you need to make three axes. As a material, automotive axles or other similar material will be suitable. On the leading axis, the author dashed the pattern, as a result, there were denticles with which the shaft clings securely to the pipe.

In addition to the axes, we will also need to make thrust washers that will hold the pipe on the sides. Washers can be machined from round timber or thick sheet steel. At the end of each washer, drill a hole and thread the screws.

Among other things, at this step the author made bearings for bearings, for this a round pipe of suitable diameter was needed. If the pipe is large, it can be cut and compressed.

For the original appearance, the author covered the washers with a black patina.

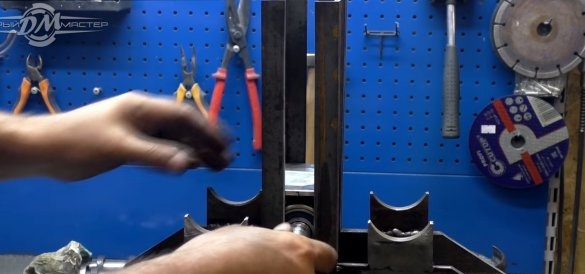

Step Two Supports for driven shafts

We make bearings for the bearings of the driven shafts, here we need thick sheet steel. Using a drill and a crown of a suitable diameter, we drill holes in the steel, and then we cut out the formed “forks”.The parts are reliably welded to the base, which is a piece of the channel. Well, then we weld our bearings in cages to the bearings.

Step Three Drive axle with movable unit

The driving axis is located in the movable block, steel angles are used as guides for this block. As the basis for the movable block, we also use a channel piece and make supports, as on the basis. If there is no such channel, it can be welded from the corner.

Step Four Push unit

The author adapted a construction threaded rod and two elongated nuts as a pressure unit. Due to the large length of the thread, the assembly can withstand heavy loads and will serve for a long time.

In the upper part, we weld a support from thick sheet steel to the guides and vertically weld our welded elongated nuts to it.

The threaded rod needs to be finalized, at one end there will be a pressure washer, and at the other end a head is installed for installing the handle. The author turned the head on a lathe and covered it with a black patina.

Step Five Painting

Paint the machine so that it does not rust and pleases the eye. We seal the bearings and other parts with masking tape and proceed to painting. The author used a beautiful green enamel that can be applied directly on rust. Now the machine looks great.

Step Six Final touches and tests

At the end, we will make a handle from a piece of pipe and a steel plate for rotating the working shaft. The handle itself is made of wood, it is a file handle or the like.

The machine can be tested, the author as an experiment bends a rectangular profile tube into a circle, the machine easily copes with the task. On this, the project can be considered successfully completed, the home-made turned out to be useful and reliable. I hope you enjoyed the project and found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!