I welcome all fans to craft, today we will consider how to make a small lathe from an old motor from a washing machine. The design of the machine is simplified to the simplest, homemade able to turn the bars into handles for tools, you can also sharpen sticks and so on. The clamp of the machine is designed for wood processing, but you can try to make a clamp for steel. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- engine from an old washing machine;

- board for the base;

- screws and nuts;

- corner;

- bolts, nuts, bearing (for tailstock);

- steel bars, plates, etc.

Tool List:

- drill;

- welding machine;

- grinder;

- marker, ruler, tape measure.

Lathe manufacturing process:

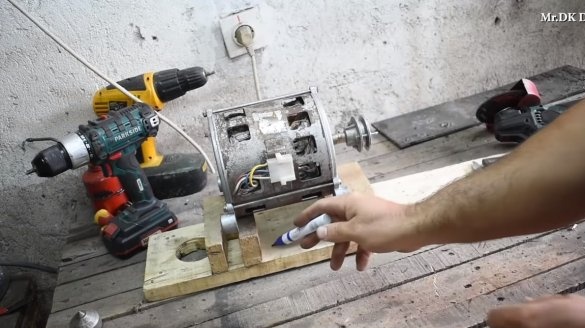

Step one. Front headstock

First of all, we will manufacture the front headstock, an aluminum pulley has already been made on the motor, which is to be redone. We mark everything and drill three holes in the pulley at the same distance from each other. After that, we drill holes at right angles for the screws. The author sharpened the ends of the screws, and then we install the screws with nuts and grovers. As a result, spikes were obtained, with which the grandmother would cling to the bar.

As for the motor power, this question remains unknown, but judging by the size, the motor has a power of at least 200-250 watts.

Step Two Installation of the motor on the bed

Next, we install the motor on a bed, using a piece of a thick board as the basis. We need to raise the engine above the base, for this we cut the bars. The author uses steel corners as brackets, we fasten them to the base with self-tapping screws, and then to the corners we fix the engine with bolts and nuts.

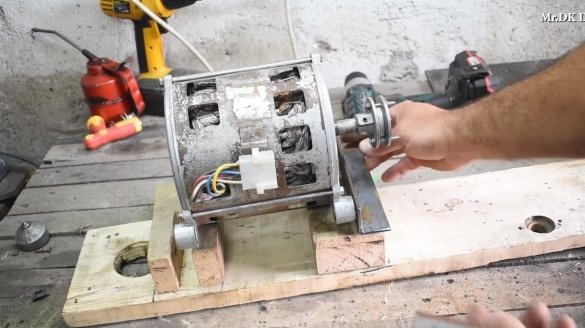

Step Three Tailstock

The base of the tailstock consists of a piece of rod and a steel plate that is screwed to the base. At the end of the rod, we weld a nut into which the headstock threaded shaft is wrapped.At the end of the shaft there is a stop in the form of a cone into which the bearing is inserted.

Step Four Test

The machine does not have enough support, its author has welded from scrap metal, the emphasis can not be screwed on and held with one hand. Now the machine can be tested, the author easily makes an excellent handle for a file from a bar. The machine copes with the task, which means it makes sense to make it more convenient, reliable and of high quality, everything is already in your hands. This is the end of the project, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!