Hello to fans of craftsmen, today we will consider how to make a simple and convenient drilling machine for 12V. Homemade the author assembled from metal, steel rods are used as guides. The stroke of the drill chuck is small, but the drill assembly is adjustable in height.

The homemade product is made as simple as possible, the machine works great and looks great. The author used the famous one as a motor, and also ordered a small drill chuck with an adapter, which is placed directly on the motor shaft. The homemade product works fine, and you can power the motor with a voltage of up to 24V. It will not be superfluous to install a speed controller on the machine with the function of maintaining high torque. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- ;

- (optional);

- small drill chuck and adapter;

- spring;

- small bearing;

- steel plates;

- the stock from the car hood;

- steel flat rod (for the guide);

- steel square or thick plate;

- screws, washer nuts;

- two steel clamps (for mounting the motor).

Tool List:

- grinder;

- welding machine;

- drill;

- vise;

- vernier caliper;

- tools for threading.

The manufacturing process of the drilling machine:

Step one. Base and main shaft

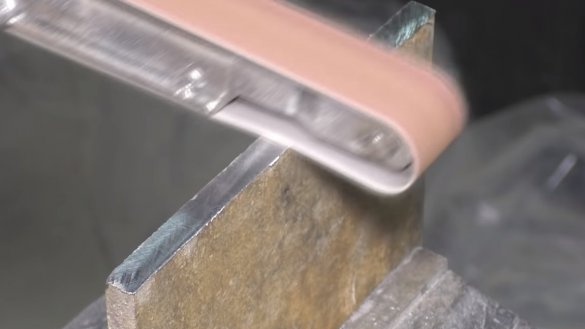

As a basis, you need a piece of thick sheet steel, the author turned out to be rusty and with sinks, so the material had to be polished for a long time. Of course, ideally, such a sheet should be driven off by a milling machine, but the author did not find such a machine.

Next, we need a stem from a gas spring, such rods are in furniture springs, but the author disassembled the gas spring from the trunk or hood auto. It is important to know that there is air under pressure inside such springs, so first we drill a small diameter hole in the housing so that air can escape through it.There may also be oil in the spring; it needs to be drained. Well, then we cut the gas spring and get the stem.

The steel rod must be clearly welded to the base at right angles. The author first drilled a hole in the base, inserted the stem, and only then welded it. That's all, after that the base can be painted.

Step Two Engine preparation

The author used the motor 775, which together with a drill chuck is possible. The author’s kit turned out to be a little defective, there were no suitable screws for attaching the adapter to the motor shaft. As a result, the screws were made independently.

Step Three Movable unit

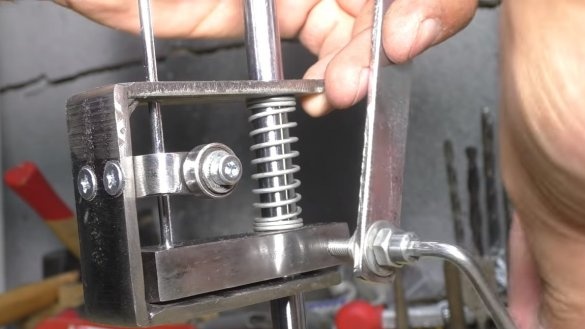

Now we will assemble the movable block, this part of the frame will ride on the rack and the engine will be mounted on it. We weld the construction of steel plates in the form of the letter "P". Holes need to be drilled around the edges of the product so that the part can move up and down the rod. The author first drilled holes of a smaller diameter than the rod, and then turned them to the desired size using an adjustable sweep.

Next, you need to make a part that will not allow the block to rotate around its axis. Here we need one more smooth steel axis, this can be obtained from the old drive. And also we make a basis for an axis from a square or a thick steel plate. The base will be attached to the rack with a screw, as a result, the machine can be adjusted in height. We drill a hole and cut the thread for the screw. As for the steel rod, it can also be screwed to the base with a screw.

Step Four A pen

We make a handle for a drilling machine, the author made it of a steel plate. The handle is pivotally attached to the part that holds the thin guide axle. Well, the emphasis for the handle is on the movable block, it is a small ball bearing screwed by a screw.

Step Five Engine installation and testing

The author secured the engine with two steel clamps, it is fast, reliable and simple, and the motor case does not need to be spoiled. That's all, solder the wires to the motor contacts, connect the power supply and you can test the machine.

Homemade easily drills a coin, the machine turned out to be successful. Also, as an experiment, you can put a milling cutter in the machine chuck and work like a small milling machine. The project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!