In this article, a master-craftsman will show us how to make a knife from electrodes. Electrodes that the master uses to weld a stainless steel.

Tools and materials:

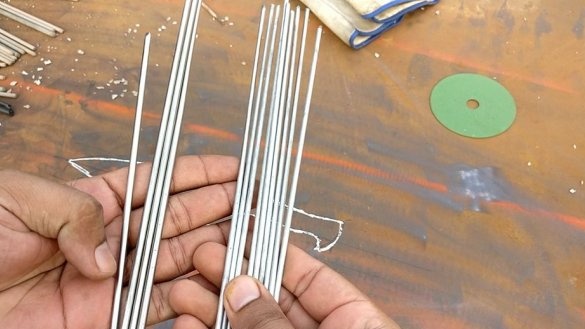

-Electrodes;

- Etching agent for stainless steels;

-Metal brush;

-Welding equipment;

-USHM;

-Various disks for angle grinders;

-Polishing composition;

- Forging equipment;

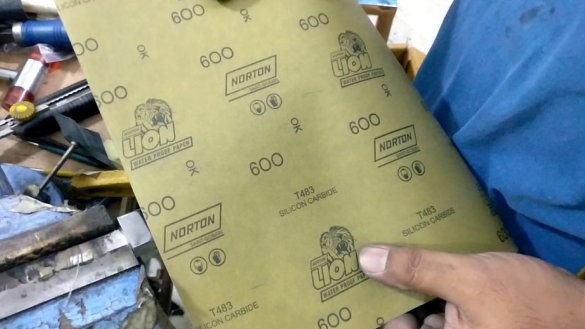

-Sandpaper;

- Files;

-Hammer;

-Vise;

-Capacity with water;

-Flour;

-Salt;

-Leather;

-Libra;

-Sheet metal;

-Drilling machine;

Epoxy resin;

Step One: Welding

First you need to clean the electrodes. The master studs the coating with a hammer, and then strips the electrodes with an angle grinder.

On the desktop, in chalk, draws a sketch of a knife. On the sketch spreads and welds the electrodes. Welding produces tacks. The cut edges are welded with a carbon electrode.

Next, the master cleans the welds with an etching agent. It is necessary to thoroughly clean the seams, if there is slag, this will ruin all the work.

Now the master boils the blank "blank". Periodically cleans it of slag. When it finishes one side, it again cleans the workpiece with an etching agent. After cleaning, boils the second side.

Step Two: Forging

The master heats the workpiece and forges it.

Step Three: Processing

After the workpiece cools down, the master first grinds it with a angle grinder, and then processes it with files. Displays descents, butts, etc.

Step Four: Heat Treatment

Next, the master hardens the knife. For this operation, you need to mix the charred skin, salt and flour, in a ratio of 6: 4: 3. Then you need to add a little water and carefully move everything. This mixture needs to be coated with a knife blade and left to dry for a day. After a day, the master packs the knife in a metal container. This is done in order to heat treatment without oxygen.

Then the master will put the container in the oven. Processing time in this way is about 50 minutes. But the fact is that after 15 minutes the container completely burned out together. With this treatment, the workpiece must be insulated with clay, and the master made a metal case. The master had to cool the workpiece in a container of water.

Step Five: Grinding

Once hardening is completed, the master begins grinding work. First removes the scale using an angle grinder. Then he processes it by setting the stone in the drilling machine. It takes down the slopes and makes the grooves with a file, and then with a file. Sanding with sandpaper.

Step Six: Pen

The master makes a pen from a block poured from epoxy resin. Drills a hole in the center of the block face. Inserts a knife handle into the hole. He grinds the handle giving it the desired shape.

Seventh step: polishing

Next, the master polishes the handle and blade with polishing paste.

Step Eight: Gradient and Sharpening

The master decided to burn the blade with a gas burner. This treatment will give the metal a rainbow color. It is important here not to overheat the blade. Stop processing when the edge of the blade becomes a straw color.

After such processing, the master sharpenes the blade.

Step Nine: Build

The master makes cuts on the shank of the knife. Epoxy is poured into the hole in the handle. Installs the shank of the knife in the hole.

Now it remains to wait for the resin to solidify and the knife is ready.

The whole process of making a knife from electrodes can be seen in the video.