In this article, the wizard will show us how to make a simple aluminum adjustable mandrel for a metal lathe. With this mandrel, the master is going to make rings.

For its manufacture, the following

Tools and materials:

-Lathe;

-Aluminum billet;

-Screw;

-Screwdriver;

-Set of drills;

-Bandsaw machine;

-Calipers;

-Marker;

-Tap;

-Vise;

Step one: aluminum billet

For the manufacture of the mandrel, an aluminum billet of cylindrical shape is needed. The diameter of the workpiece does not matter, the main thing is that it is installed in the chuck of a lathe.

The master cuts off six centimeters of the workpiece.

Step Two: Hole

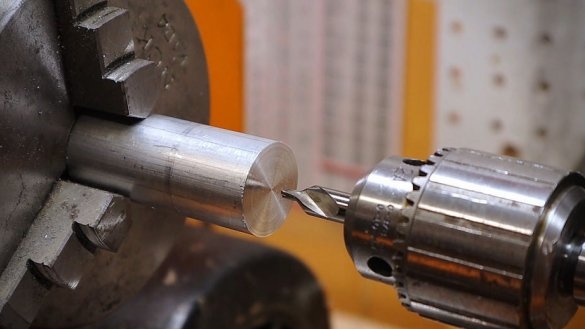

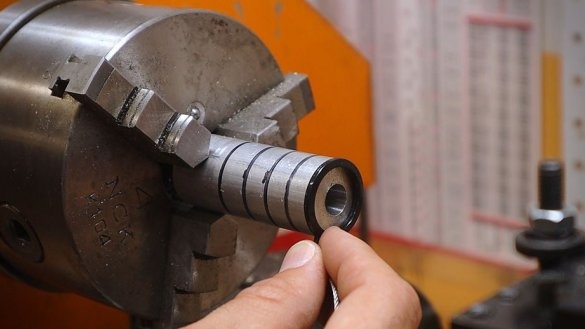

Sets the workpiece into the chuck of the lathe.

It processes the end face of the workpiece, making the plane perpendicular to the axis.

Makes a countersink in the center of the workpiece.

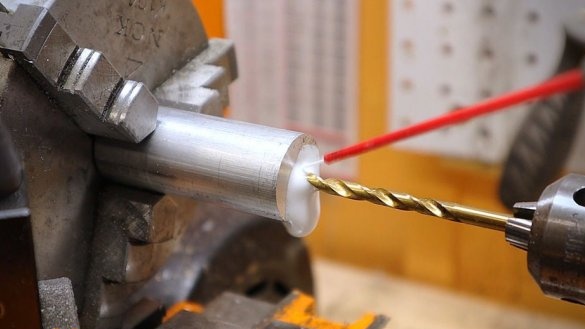

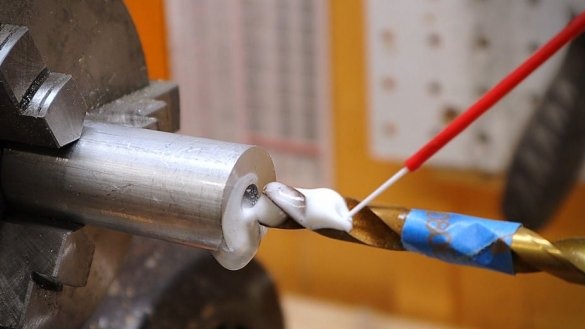

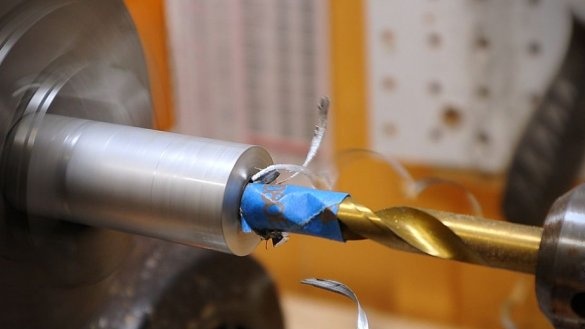

The first hole is through. His master drills with a 13/64 drill (5.15 mm).

The second hole is drilled with a 25/64 drill (9.13 mm) to a depth of 3.8 cm.

Step Three: Groove

Next, the master measures the diameter of his little finger, index, middle and ring fingers.

Next, you need to grind the workpiece along the diameter of the measured fingers. The first groove starts from the cartridge to the largest diameter. Then the master steps back a little and pumps it to the next diameter and so on to the end.

Step Four: Carving

Countersink screw hole.

Now you need to remove the workpiece from the cartridge, install in a vice and cut the thread.

Step Five: Cuts

Now the master makes cuts on the band saw machine.

Step Six: Verification

To check the mandrel, the master installs it in a lathe, puts a ring on the mandrel and fixes it by turning the screw.

Everything works.

The whole process of manufacturing such a mandrel can be seen in the video.