In this article, we will consider how you can independently assemble a CNC milling machine. There will not be all the details in detail, only general information, direction.

The master had not done such projects before and making a machine was his first serious work of such a plan.

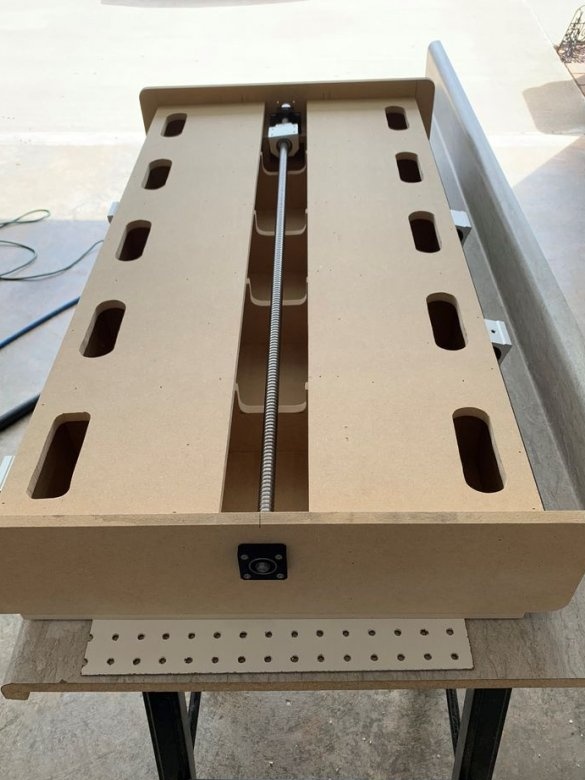

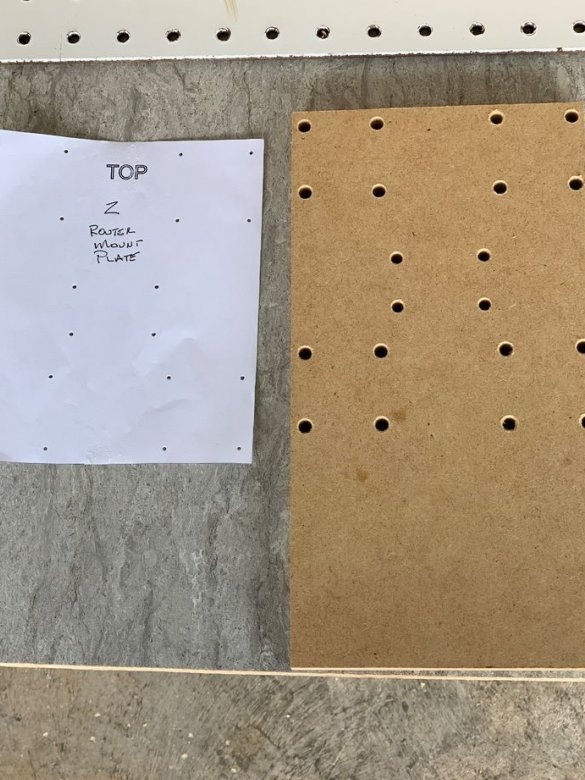

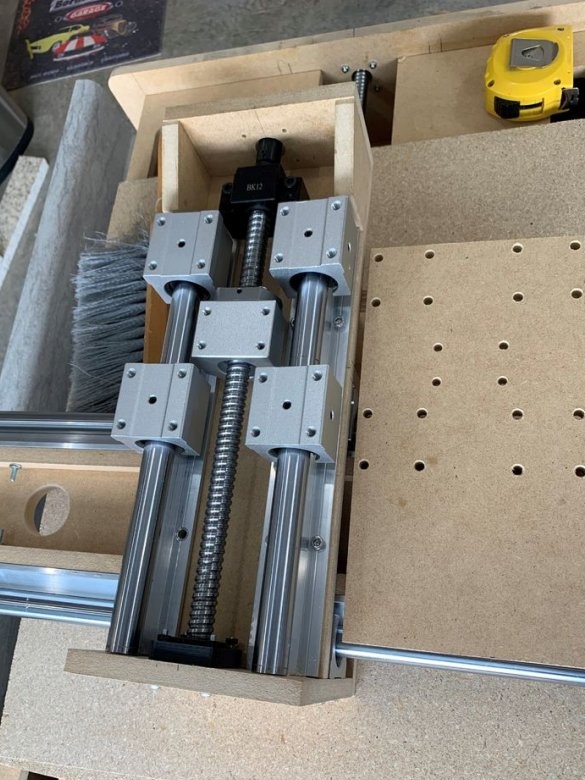

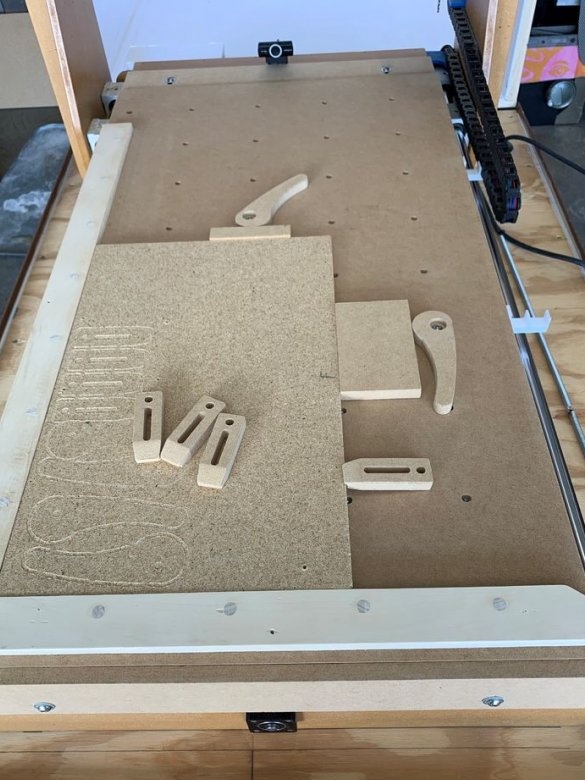

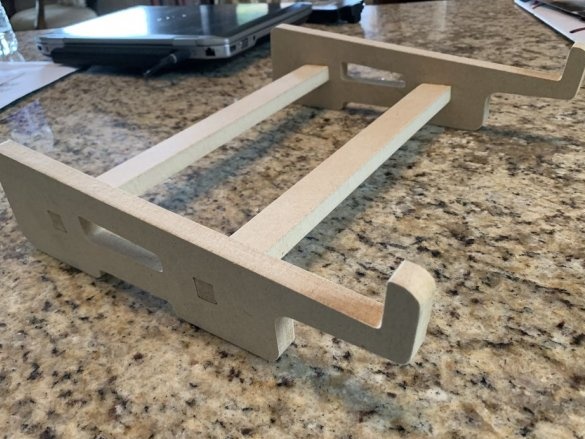

From MDF master made a frame. The dimensions of the bed were designed taking into account the size of the guides. The guides have the following dimensions: Y - 1000 mm, X-600 mm and Z-300 mm. Holes are drilled on the desktop for mounting workpieces. MDF thickness 110mm. To give strength, the master added stiffeners.

The master used NEMA 17 engines to move. This motor can move any axis at a speed of 3200 mm / min and cut at a speed of 1600 mm / min.

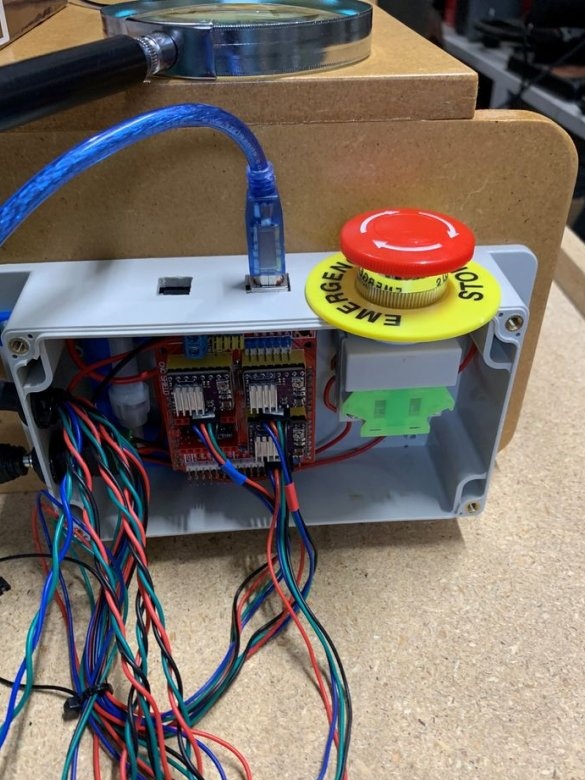

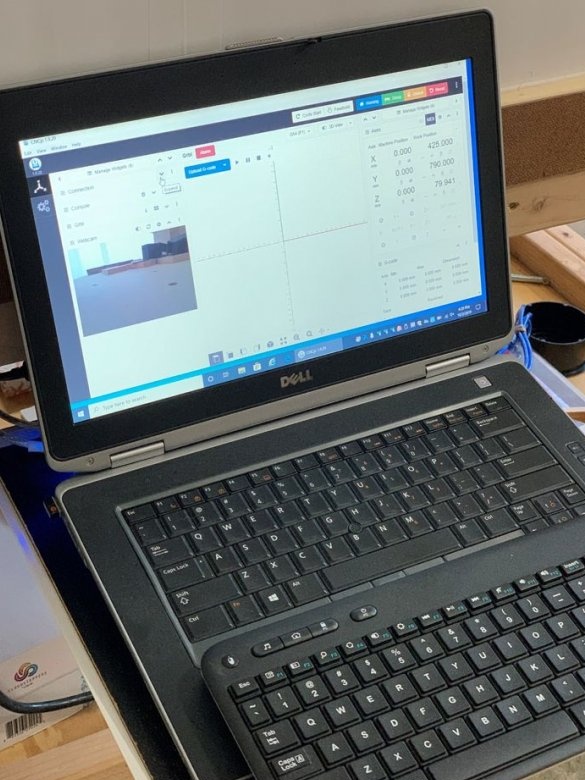

To control the wizard installed Arduino UNO with GRBL and GRBL Shield 8825 controller.

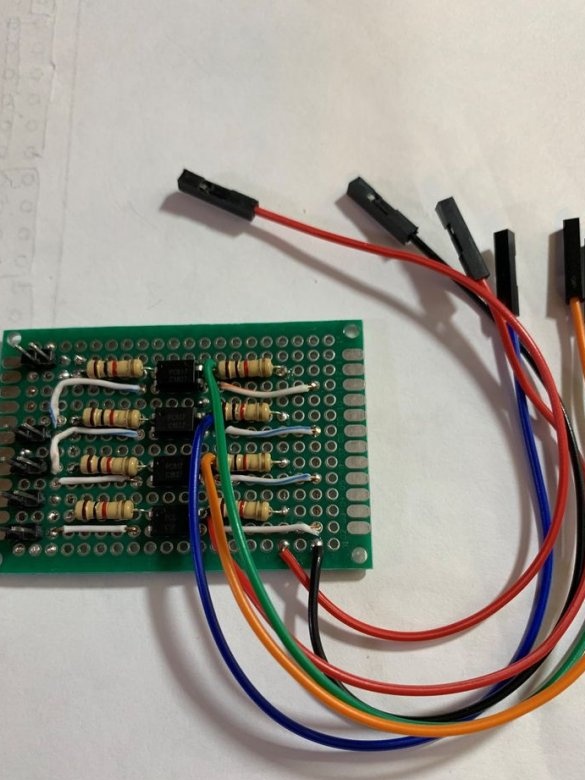

The master made a board with 4 optocouplers to prevent false alarms at the limit switches.

Powered by a laptop power supply unit 20 V - 7 A. Actual power is only about 2 A.

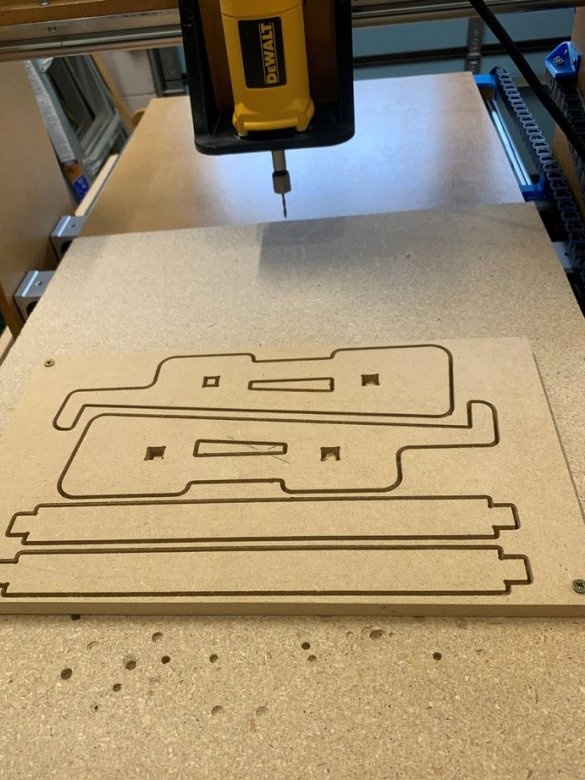

As a milling cutter, the master used the Dewalt 660.

The master uses the Fusion 360 program to design parts.

To prevent dust from scattering in all directions, the master made a foam fence.

Although the master did not have experience, everything turned out the first time. The machine works and performs its functions.

The machine cost the master $ 400, but it is cheaper if he bought a machine of this size.