Everything happens in life, so it’s good to know everything in order to get out of a difficult situation. Ahead is winter, which means that many will have problems starting the engine. Even if the battery is new, it costs nothing to land due to inexperience, rotating the frozen motor. And to charge the battery for a long time, and not everyone can have a charger at all.

I will show you how to safely start a DC motor. In mine there is no function to start the engine, and the inverter outputs about 65V at the output, the maximum current is 250A.

How much starter is eating?

When working in harsh conditions (winter), the starter consumes around 150-200A, we are talking about modern starters on modern cars. My old KATEK easily eats 250-300A.

The welding machine we produce 250A, this is a current limit. Thanks to this limitation, you will not burn the starter at any voltage, even at 220V. Of course, it is better to increase the current gradually, 250A for a modern starter is already a lot, it is better to start with 100A.

Generally speaking, the inverter and starter are a great company.

Onboard network

The vehicle’s on-board network operates from a voltage of no higher than 17-20V, usually at 20V bulbs and other devices already burn out. Usually in the on-board network of the order of 13-13.5V (it all depends on the machine).

If you give 65V to the on-board network from the welding inverter, everything that was included in the network will burn for you in an instant. And the ignition coil, the generator relay, the dashboard, the gas tank sensor will be included in the network, the retractor of the starter will also suffer.

Generally speaking - the inverter and the on-board network are atomic bomb, the car, at best, will not burn down completely!

Way out:

To start the motor from the inverter, without breaking anything, the on-board network must be connected to the battery, it can be sunken in trash, you need 9, 8, or even less volts, the most important thing is that the battery pulls the retractor starter, and enough for a spark. Then the generator will work, and the voltage of the on-board network will be normal.

Well, at the power input of the starter, we feed our bold "+" from the welding inverter, DO NOT FORGET TO DISABLE THE BORTNET. We sit in the lounge and calmly start the key. Do not forget about safetyso that the inverter does not fall off after starting, and the circuit is not shorted!

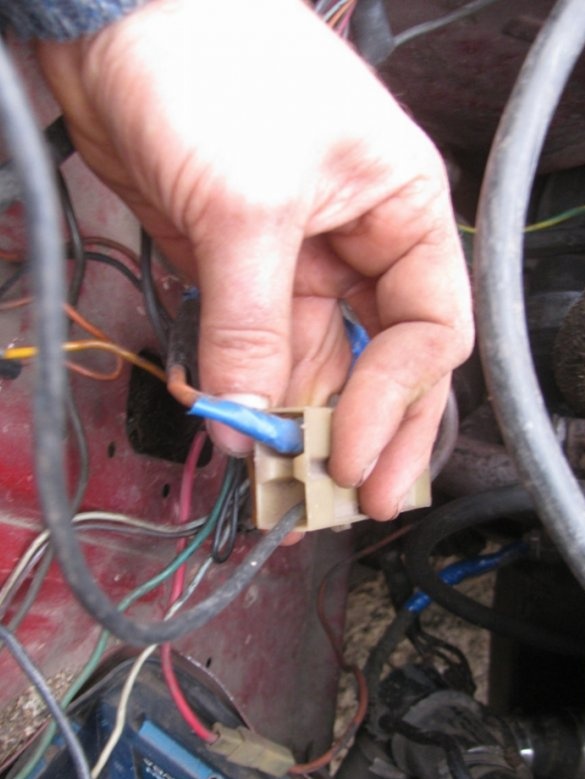

On an old VAZ 21-classic, the wiring system is easily disconnected from the main power wire that goes to the starter.I made a separate terminal from the wire and separately applied “+” from the battery to the onboard network.

Fashionable youtube way to start from the welder. DO NOT REPEAT!!!

The bottom line is that the power from the inverter is supplied directly to the dead battery, as a result, the voltage sags and the engine can be started. But keep in mind that such a method is unpredictable, at any time the contact between the battery may be broken and your clunker will burn to hell!

And it will be with your flight system!

How to “push” a battery with an inverter?

If you need to recharge the battery so that it at least pulls the retractor, connect the battery through the electrolyzer, which will limit the current. I do not recommend connecting the battery directly to the welder, you can kill the inverter and so on.