Hello to all lovers of working with steel, today we will consider a simple and effective tool for cutting steel. The manufactured machine does not even cut, but cuts steel, everything works on the basis of a powerful press. Homemade the author collected in order to cut semicircles in a square profile pipe, so that the pipes can then be conveniently connected. Using such a machine, the author assembled an interesting metal staircase. Depending on your needs, the machine can even cut circles or other shapes, depending on your needs. The author made knives from an automobile spring, steel perfectly copes with the task. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- car spring;

- thick sheet steel;

- steel bar;

- profile pipes;

- square rods.

Tool List:

- grinder;

- welding machine;

- vise;

- tape measure, marker;

- tape cutting machine.

Homemade manufacturing process:

Step one. Making knives

First of all, we will make knives that will cut steel. As a material, the author used a car spring from a truck. Cut off the piece we need and start cutting. In one half of the plate we cut out a semicircle, the author carries out the work with a grinder, the metal had to be cut into pieces. At the end, we trim the semicircle with a thick grinding disc.

The second knife is also a semicircle, it will go into the semicircle that we cut in the plate. Of course, after all the work it would be good to harden the steel, then the knives will serve for a very long time, but the author omitted this moment.

Step Two Guides and stock

We make a stock and guides for it. As a material, the author used a thick steel bar, such a rod just does not bend under heavy loads. The author sealed the semicircular knife through the spacers well to the stock.

Step Three Frame and base

We assemble the frame on which we fix the knives and guides.As a basis, the author used thick sheet steel, and to make everything as durable as possible, we reinforce the frame with rectangular steel rods. It remains to weld the knives and guides to the frame.

We also weld pieces of profile pipes to the frame, which will serve as the base, a kind of legs.

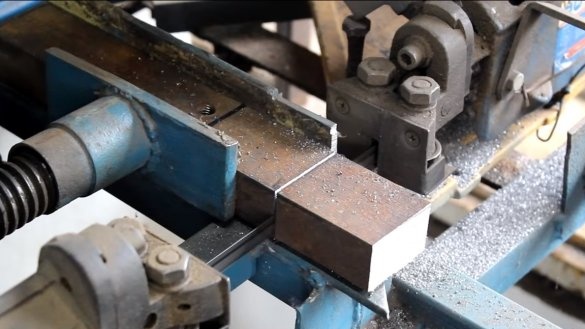

Homemade ready, you can experience. As an experiment, the author cuts semicircles in a steel profile pipe with a wall thickness of 3 mm. The machine easily copes with the task. Of course, over time, the knives become dull, as our steel is not hardened, but in general everything works fine. The project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!