Hi everyone, this time we will look at how to make a construction mixer that can be powered by a chainsaw. In fact, homemade is the result of remaking an old, out-of-operation electric mixer. The made homemade product is just a nozzle for a chainsaw and does not change its design in any way. The mixer works perfectly, it does not depend on the mains, and gasoline such a useful homemade product will consume very little. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- faulty electric construction mixer;

- Sheet steel;

- bearings;

- steel pipe;

- grease;

- screws;

- paint for metal.

Tool List:

- lathe;

- drilling machine;

- grinder;

- vise;

- tape cutting machine.

Homemade manufacturing process:

Step one. We disassemble the construction mixer

First of all, we’ll take a look at the construction mixer, he has the Collomatic DUO 1200 brand from the author. The engine has a power of only 1.2 kW, in the selected chainsaw power of more than 2 kW, so that the saw will pull the mixer without any special loads, which is already good.

Having disassembled the gear section, the author found a strange color grease, it is quite possible that this is an emulsion, a mixture of grease and water.

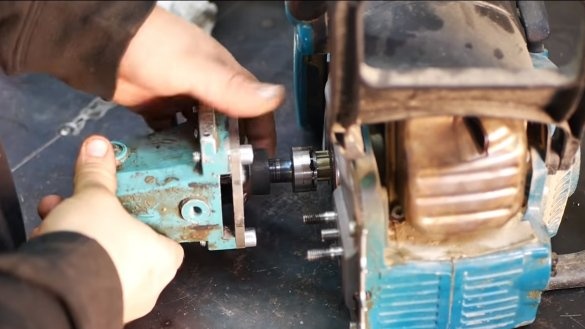

We disassemble the motor case, inside there is an anchor, cut it in half and knock out a piece of the axis.

Step Two Finalization and installation of the axis

We clamp the axis of the anchor in the lathe chuck and remove a certain amount of metal, we will need to install an additional bearing on the axis.

Under the bow of the motor we cut out a steel plate, drill holes for the screws and the working axis. We also need to make a cage for an additional bearing, its author made of a piece of steel pipe. In the pipe, you need to select a certain amount of metal so that the bearing can be pressed into it. To fix the bearing, the author made a groove under the snap ring. We assemble the entire structure and grab the bearing race to the steel plate.Having disassembled everything, we finally firmly weld the clip to the base. The design of the bow of the engine is somewhat reminiscent of a grinder.

Step Three Coupling

We are making an adapter with which we can transmit torque from the chainsaw motor to the drive shaft of the mixer. The author machined the adapter from the round by means of a lathe. We weld an asterisk for a chainsaw to the adapter. As a result, the adapter will be connected through the slots to the clutch plate of the saw. Thanks to this design, the nozzle is quickly mounted on the saw and does not require alterations.

The coupling is attached to the mixer axis with a pin.

Step Four Mounting bracket

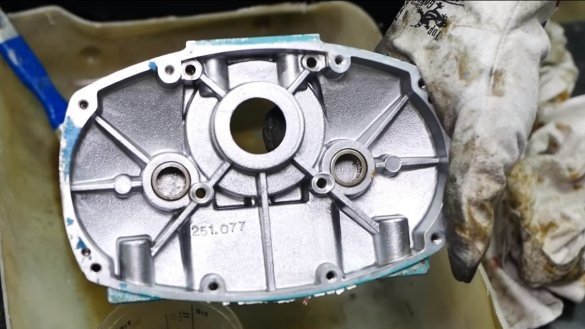

We make a mounting bracket from thick sheet steel, the fastener will be attached to the chainsaw studs to which the tire is attached. We weld a piece of steel pipe to the fasteners, and already to this pipe we weld our gearbox from the mixer, made earlier. You need to grab everything with welding on the spot, on the chainsaw, so that everything works out smoothly.

Step Five Change the grease

In all nodes, the author decided to replace the grease, because the machine will not last long with the old one. We pick out the old grease, clean the rest with a solvent. For the final cleaning, the author used a fluid to clean the brake system of the car.

Step Six Painting and assembly

We paint all the details on the outside so that the paint holds well, apply a layer of soil on the metal. After painting, all parts look like new, the nozzle can be assembled. We stuff thick fresh grease into the gearbox, do not forget to install the gaskets, and assemble the mixer.

Seventh step. Test

We install our homemade nozzle for a chainsaw, everything is done quickly and simply. We start a chainsaw and you can mix concrete. The machine easily copes with the task. Of course, if you interfere a lot, your hands will get tired of the vibrations and the heavy weight of the machine, it is better to rent a concrete mixer here.

That's all, the project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this, do not forget to share your ideas and homemade things with us!