In this article, the Wizard will tell us how to make a vacuum table. It is needed to hold the workpiece while processing it with an engraver, laser, etc.

To make a table, the master uses the following

Tools and materials:

-Board;

-Glue;

-Fasteners;

-Plywood;

Expanded polystyrene;

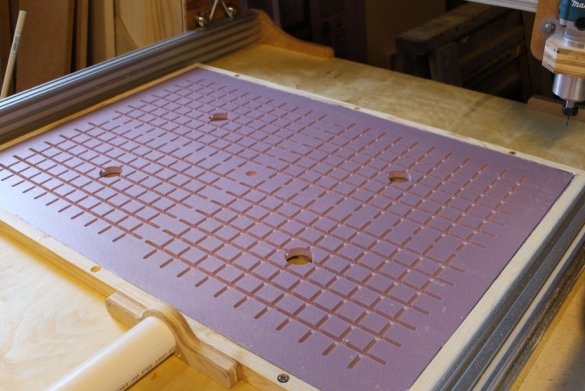

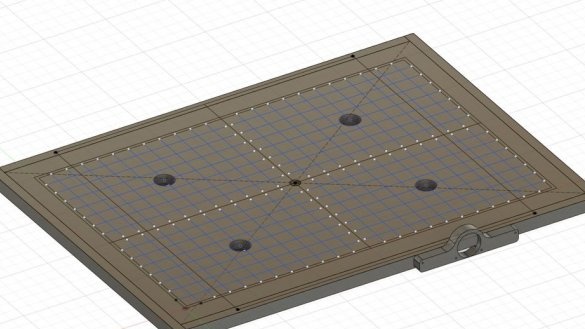

Step One: Design

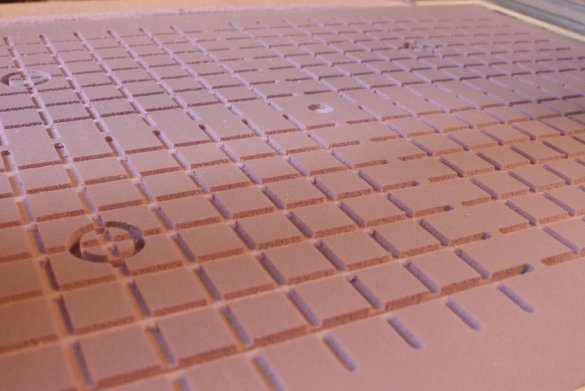

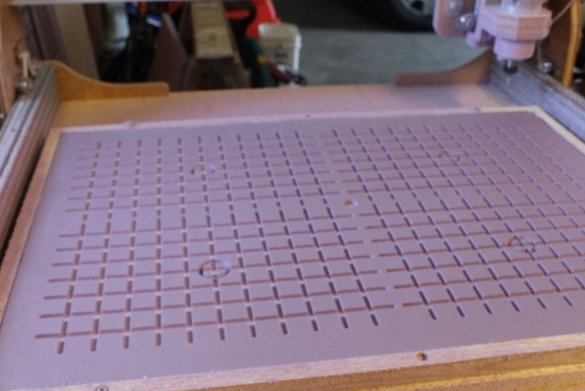

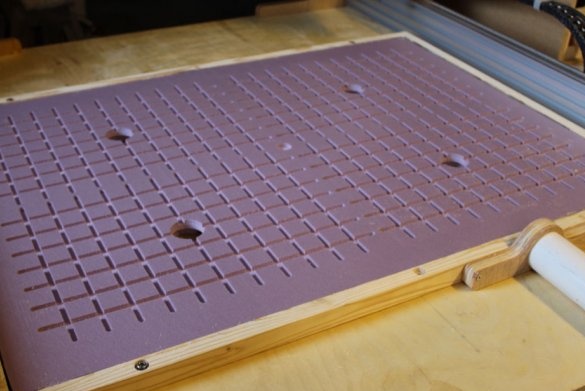

The working table of the CNC machine for which the vacuum table is made is 90 X 75 cm. The working surface of the vacuum table will be 75 X 50 cm. The whole vacuum table is divided into squares that divide the grooves. From below air channels are made through which air is pumped out.

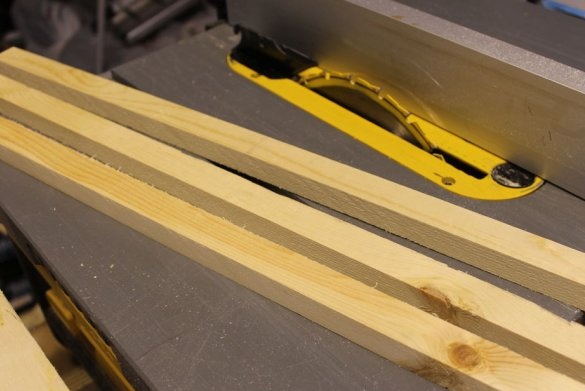

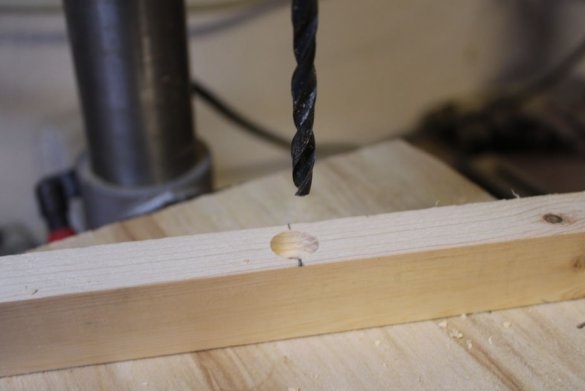

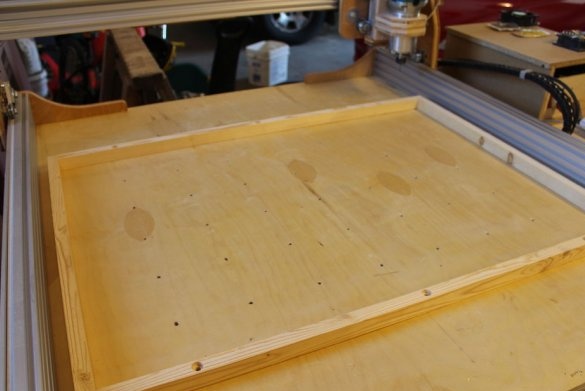

Step Two: Frame

From the board, the master makes and assembles the frame.

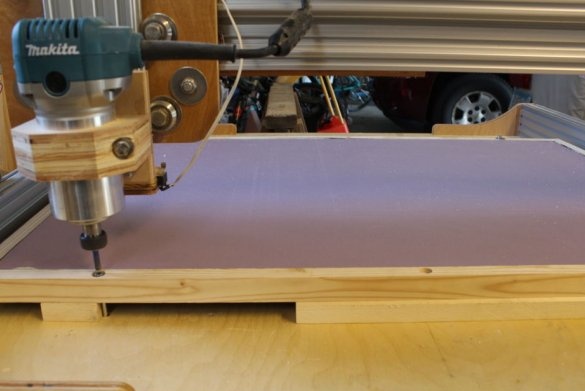

Glues polystyrene foam into the frame.

Step Three: Cutting

Then the master cuts the foam on both sides.

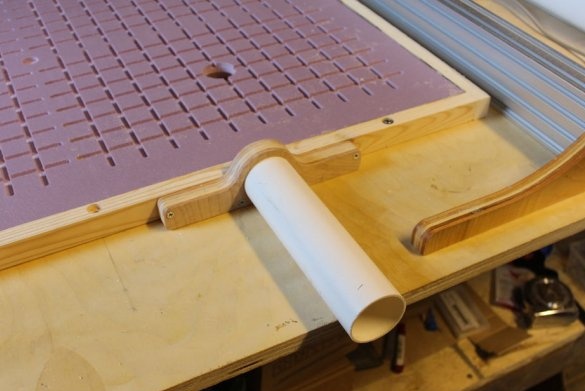

Step Four: Adapter

Makes and installs an adapter for connecting a vacuum cleaner pipe.

All is ready. To use a vacuum table, you need to place it on the machine desktop and connect a vacuum cleaner. The workpiece is placed on top of the table. If the workpiece does not cover the entire surface of the table, then you need to close the grooves around the workpiece.