I welcome all fans to craft, I propose to consider instructions for the manufacture of a jigsaw machine do it yourself. As a basis, the author adapted the motor from the compressor of the refrigerator, and in order for the motor to serve for a long time, the author even figured out how to make an oil bath. The machine turned out to be quite productive, the author puts the blade for jigsaw and easily cuts plywood, boards and more. The car turned out to be quiet, durable and quite comfortable. If you are interested in the project, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- compressor from the refrigerator;

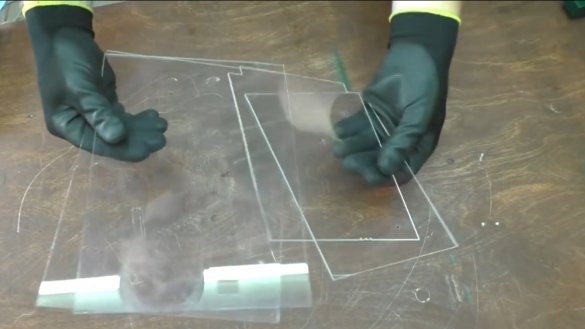

- plexiglass;

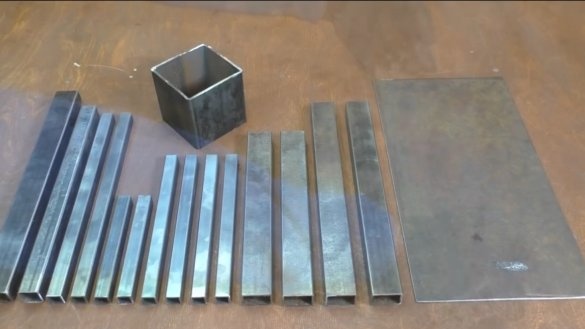

- profile pipes;

- Sheet steel;

- long nuts and threaded rod;

- bearings;

- paint;

- car engine oil;

- caps for pipes

Tool List:

- Bulgarian;

- welding machine;

- drill;

- vise;

- files;

- a hacksaw for metal.

Manufacturing process homemade:

Step one. Motor preparation

First of all, we arm ourselves with a grinder and carefully cut the compressor housing. Inside, in an oil bath there is an electric motor with a compressor. Carefully drain the oil so as not to spill. We cut off the extra tubes, and also remove the valve from the compressor, as a result, we will have access to the piston. Note that dirt will reduce the life of the motor, so we try not to litter much when disassembling and assembling.

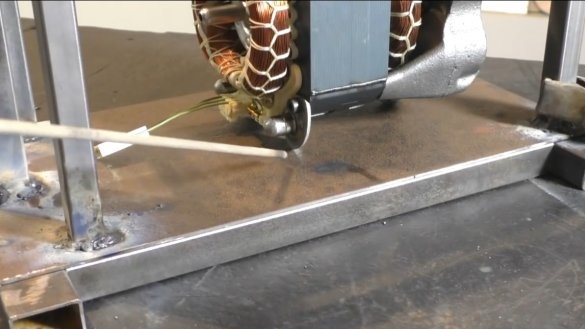

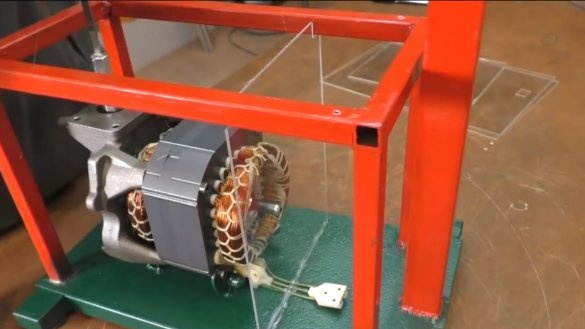

Step Two Frame

We assemble the frame for the machine, there is nothing complicated, we use profile pipes as the material, and you can install a sheet of steel at the bottom. The essence of the design is that it can then be glued to plexiglass and thereby make an oil bath for the engine. We also install the stand in the form of the letter "G", there will be an emphasis for the cutting blade. All welds must be thoroughly cleaned, the pipes must also not be dirty or in rust.

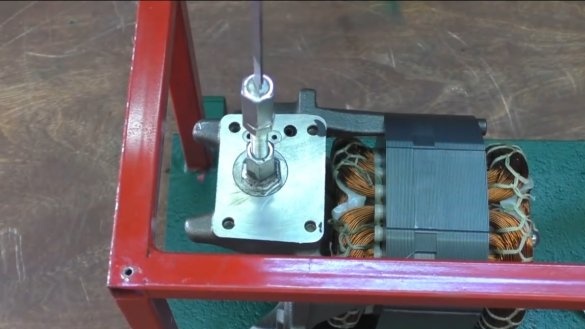

Step Three Piston Mounts

We need to make fasteners on the piston, in which we wrap a bolt or a threaded rod. As such fasteners, the author came up with a long steel nut to be welded to the piston. It is necessary to cook carefully so as not to damage the cylinder and not litter with slag.

Step Four Plugs and motor mount

We open all ends of profile pipes with plastic plugs. The motor will need to be securely fixed to the base, fasteners are made from pieces of a profile pipe, corner or similar material.

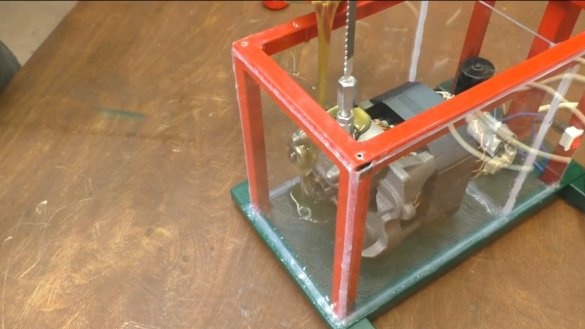

Step Five Emphasis

Under the cutting blade of the jigsaw you need to emphasize, as the basis, the author used a corner. We drill holes and thread the screws. The author used three bearings as stops; we fasten the bearings with screws. The emphasis should be adjustable, we make a slot hole that will allow to move the emphasis.

When everything is ready, the frame and other steel parts can be painted.

Step Six Cloth clip

We make a clip for the canvas, the author took a bolt, cut off the hat, and in the rod made a cut along the hacksaw. The cutting blade for the jigsaw will be inserted into the resulting slot. To tighten the manufactured "cartridge", tighten a long nut, and it compresses the canvas. The result is a simple and sturdy construction. We wrap the other end of the threaded rod in a nut welded to the piston.

Seventh step. Assembly and testing

We assemble the machine, it remains for us to stick plexiglass, the motor should be in an oil bath. It is important to understand that everything must be done hermetically so that the oil does not leak out. Silicone is suitable as a sealant, and you can screw plexiglass with screws. The author used a simpler option and applied hot glue.

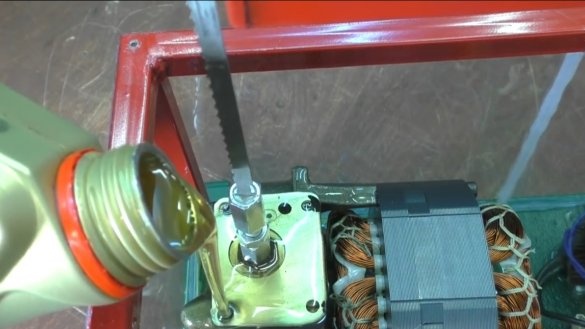

Do not forget to remove the cable from the motor, as well as install the capacitor and other parts in a protected place. When everything is ready, pour motor oil for cars into the oil bath. Oil needs to be poured so much that the crankshaft can catch it, it will already scatter oil on the cylinder and other components.

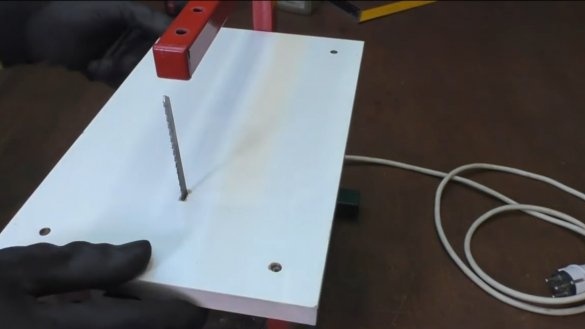

That's it, put the countertop and you can test the machine. Everything works perfectly, the machine easily cuts plywood and a rather thick board. Inside the case, you can see how the motor is lubricated. All that remains is the problem of debris that will fall into the housing and contaminate the oil.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!