Surely many of you tried to clean the overall parts from rust, or elements of complex shape, and know that this will generate a huge amount of dust. Also, you were faced with the need to move large and heavy devices and objects.

In this article, the author of the Men’s Craft YouTube channel will tell you how he made a small but powerful car, as well as an easy way to hydrolyze steel parts.

For the manufacture of the car itself, a welding machine is required, and the cleaning technology itself is very simple, and can be easily repeated even inhome conditions.

Materials

— Charger PATRIOT BCI-20M

- Steel profile pipe 25X50 mm, sheet

- Steel stud, washers, nuts M14

- Furniture wheels, caps

- Plastic container

- PVC tube

- Rubber wheels

- Screws, wing nuts M6

- Machine oil

- Soda, salt, citric acid, water

- Aerosol primer and paint.

Instruments, used by the author.

— Angle for adjustable angle welding

— Svenson Square

— Bulgarian

- Cutting and flap scraping discs

— Semi-automatic weldingmask

— Screwdrivermetal drills

— Gas-burner

— Rivet gun

- Hood

- Cairn, hammer, wrench, screwdrivers.

Manufacturing process.

To begin with, the master will make a frame for a wheelbarrow from steel profile pipes 25X50 mm. Using the Svenson square, he marks the necessary cut at 45 degrees on the edges of the workpieces.

Cuts off excess from workpieces with a grinder.

Then he proceeds to the assembly and welding of the lower part of the frame. First, three details of the future rectangle are picked up. For convenience, the author uses magnetic corners.

Now the fourth part is grabbed, and all the seams are already boiled.

Before installing the following structural parts, the seams are cleaned with a flap disc.

Then four racks are welded.

The last to weld are three elements of the upper part of the frame, and one additional crossbar.

Turning the frame upside down, the author welds two swivel castors.

Next, the master makes a handle, it needs to be slightly bent, and he makes a V-shaped cut.

By bending the workpiece, the cut point is boiled and cleaned.

On the handle and frame, the core is drilled and drilled holes for the mounting screws using oil.

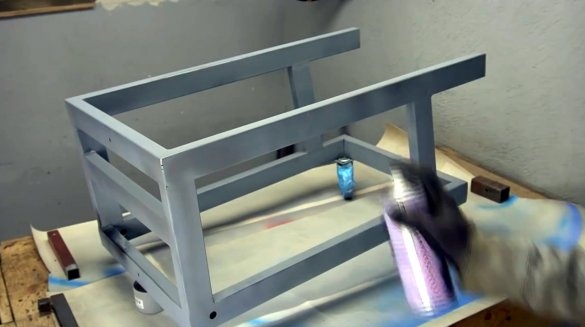

Then the frame and the handle are coated with a primer, and after drying, they are painted with aerosol paint.

The paint has dried, you can screw the handle into place. For the convenience of its removal, the master uses wing nuts.

Holes were drilled in the lower rear of the wheelbarrow, and a steel stud was installed in them, and fixed with a pair of nuts on each side.

The inner diameter of the bearings of the purchased wheels turned out to be slightly larger than the stud sizes. The master found a way out and put on a PVC pipe. So that she sat tightly on the hairpin, he heated it with a gas burner, and screwed it onto the hairpin.

Now you can install a second pair of wheels by placing washers on both sides and tightening with a nut.

The master made the pallet out of sheet steel, and secured it to the frame with a rivet gun.

And here is the main character, on the basis of which the hydrolysis process will be carried out. This is a battery charger for car batteries. For ease of use, the author mounted it on the frame.

At the ends of the handles, the master hammered plastic furniture stubs.

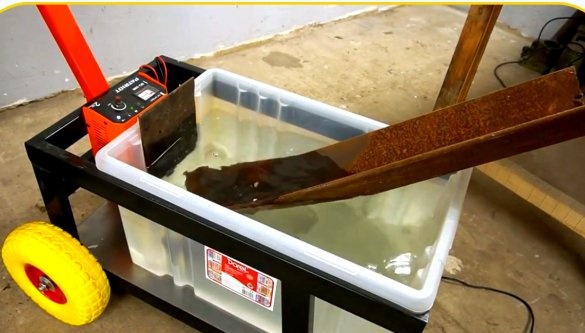

Almost everything is ready, it remains to install a plastic container, put a steel plate, which will play the role of the anode, fill the tank with water, and add soda.

Here such a rusty steel corner can be very long, with the formation of dust, cleaned of rust in the usual way. Therefore, the master cleared only the place of contact with the crocodile.

The part is immersed in the solution, a negative wire is connected to it. The current in this case is 10-15 A at a voltage of 12 V. The maximum operating current of this Battery Charger PATRIOT BCI-20M - up to 18 A, limit - 25.

Literally after 15 minutes, the entire surface was perfectly cleaned. You can turn the overall workpiece over and continue cleaning.

And such a steel sheet can be left to clean overnight by setting a small current on the charger, about 5 amperes. If necessary, and to increase the cleaning efficiency, you can install an anode of a larger area, or several cathodes. Citric acid is also a good catalyst for the reaction. Soda can also be replaced with ordinary table salt, it is much cheaper, but chlorine will be released, and you need to work only on the street. In both of these reactions, hydrogen, oxygen, and carbon dioxide will be released.

In order not to breathe the generated gases, you can roll this cart out of the workshop gates. It will also be convenient to drain the spent solution.

Now with the help of such a powerful car it is possible to transport a heavy welding machine, building mixtures, and other heavy objects.

The corner has already dried up, and now the quality of surface cleaning is even better visible. It is very difficult to achieve such an ordinary brush.

I thank the author for the simple but useful device for the workshop, as well as a simple technology for cleaning parts from rust!

If you have interesting homemade products, share them on this site. Here you will get a real reward, not a “bunch of green stuff" at the entertainment forum.

All good mood, good luck, and interesting ideas!

Author video can be found here.