Induction heater is a good tool to help the master-master for heating metal objects.

In this article, the Wizard will tell you how to make a powerful induction heater for 2000 watts.

Tools and materials:

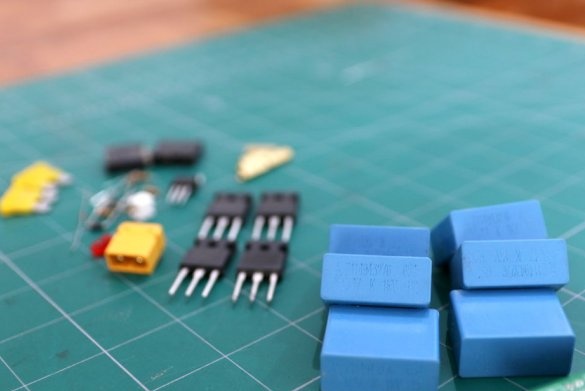

-Printed circuit board;

- Copper wire 12 AWG and 16 AWG;

-Ferrite cores;

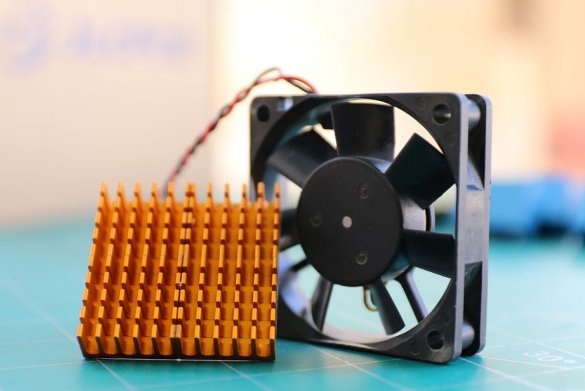

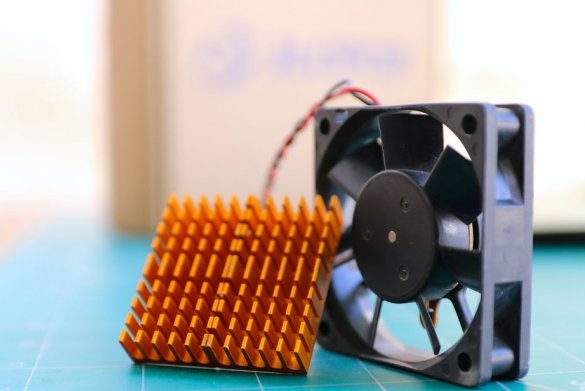

-Fan 12V DC;

-Radiator;

-Resistors;

-Capacitors;

-Diodes;

-Soldering accessories;

-Nippers;

-Pliers;

Step One: Scheme

The device works as an LC-type generator and induces current in metal objects with a constantly changing magnetic field.

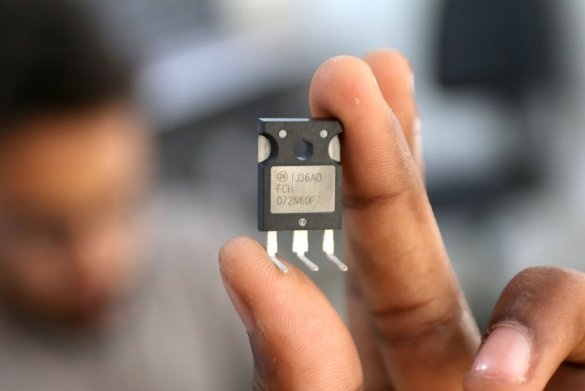

A DC voltage in the range from 12 to 36 V is applied to the input. Two fuses are installed at the input. Power is then supplied to a 12 V LM7812 voltage regulator, which is used to drive the fan, and to four N-channel amplifiers that drive two channels that operate alternately and thus change the DC voltage into a continuously changing electric field .

Now there are two possible configurations, you can either use only one built-in inductor and divide the output coil into two parts, which makes the design more complicated, or use two inductors and one coil, as the master did.

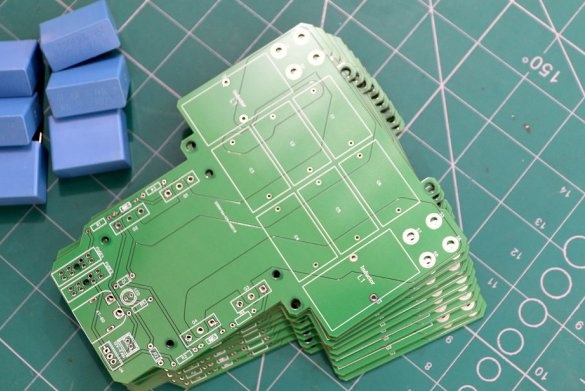

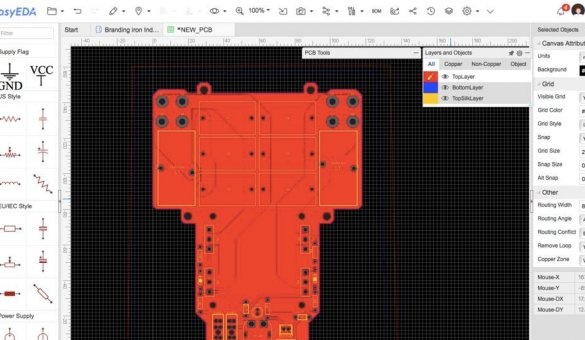

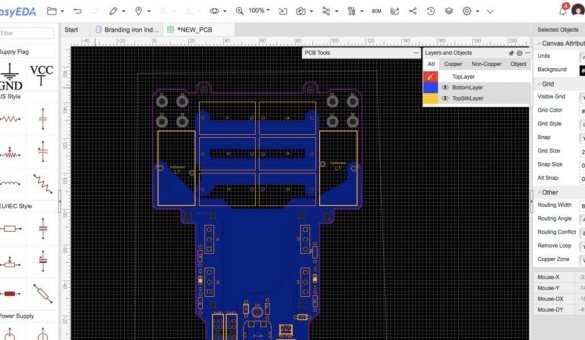

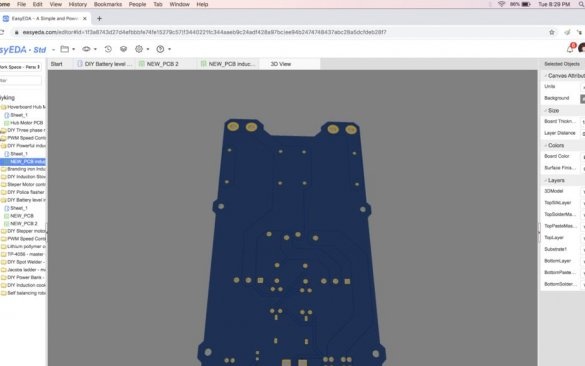

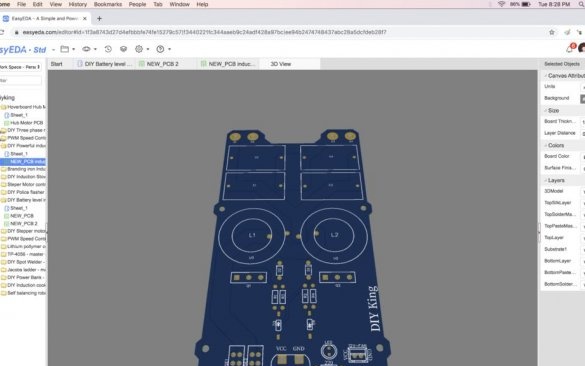

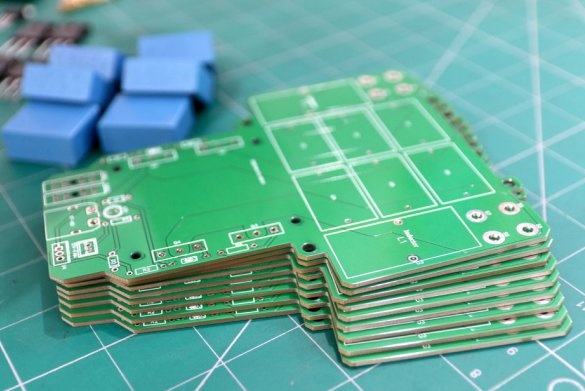

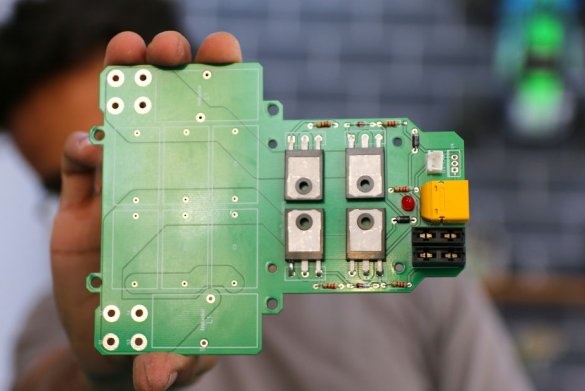

Step Two: PCB Design

Having finished work on the circuit, the master began to develop a special printed circuit board for the induction heater.

Scheme, files and specification can be downloaded from this the link.

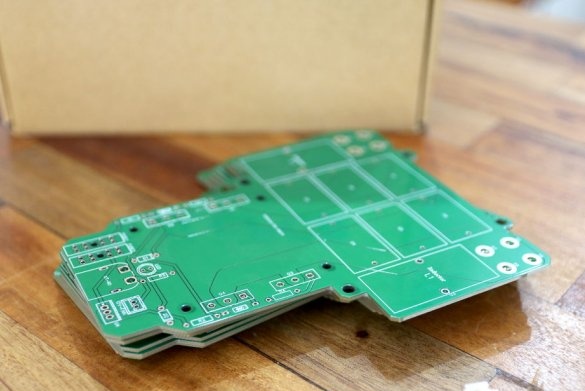

The master ordered the board at JLCPCB.

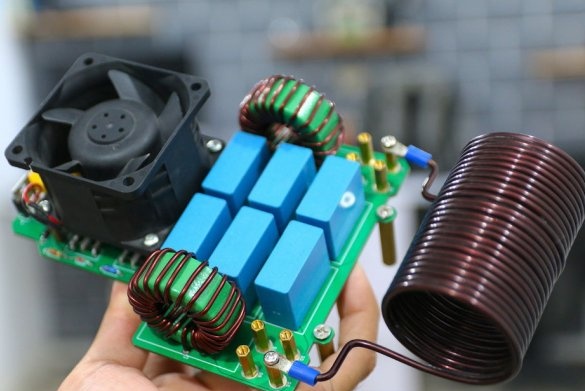

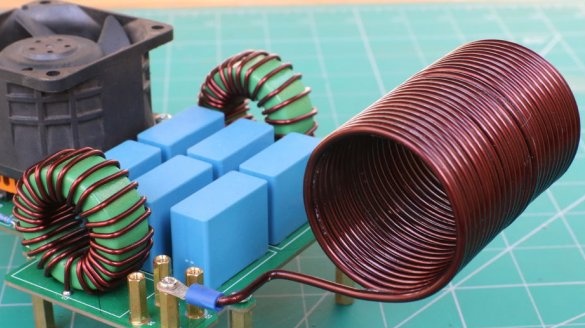

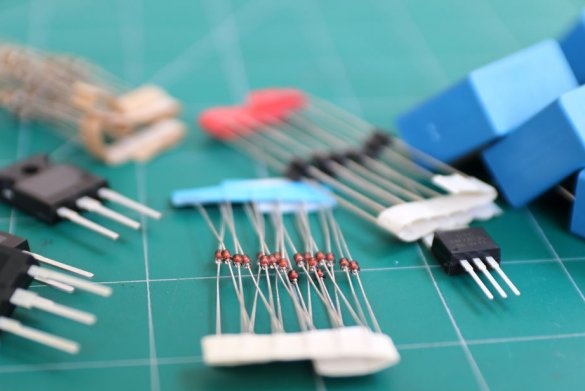

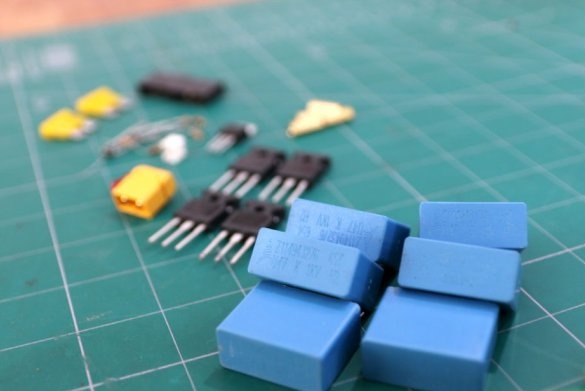

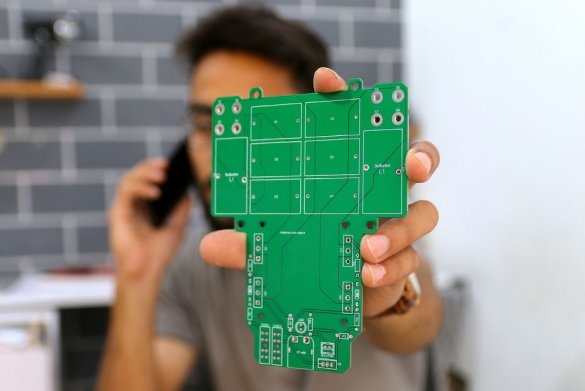

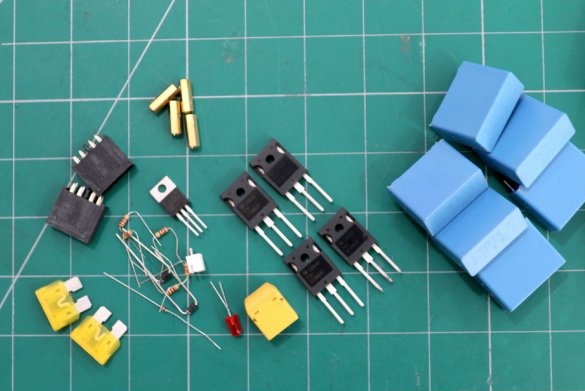

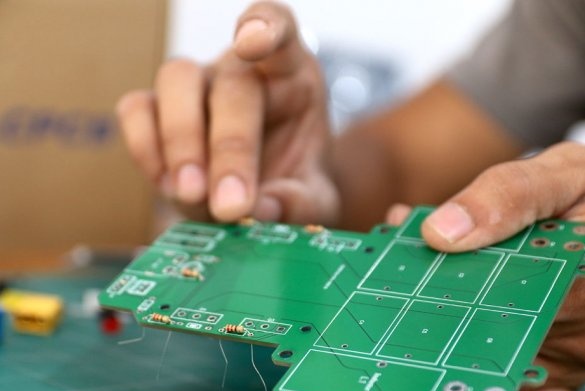

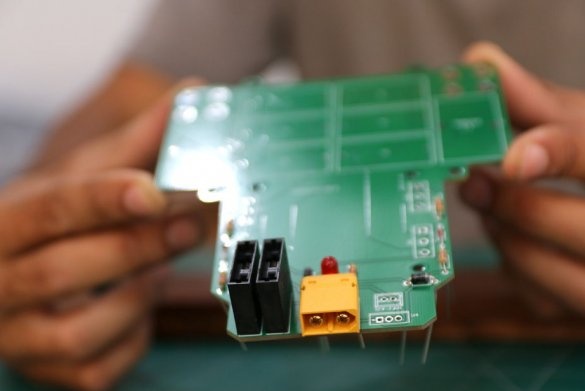

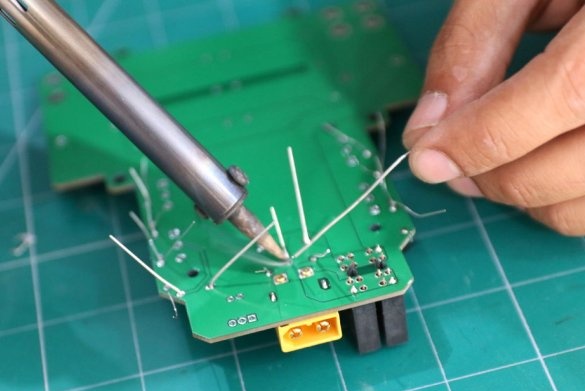

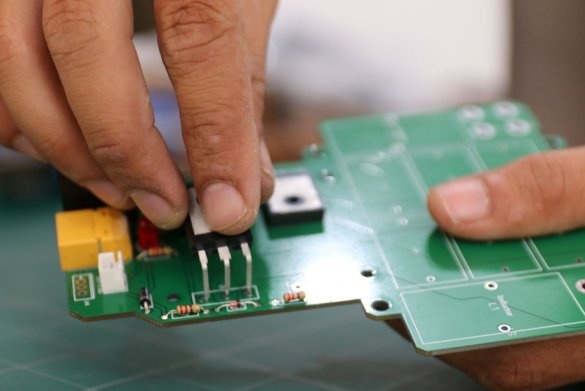

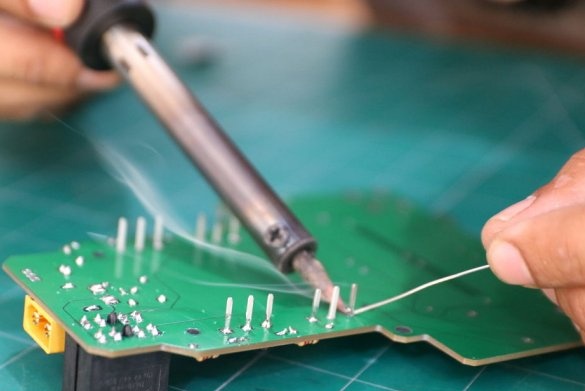

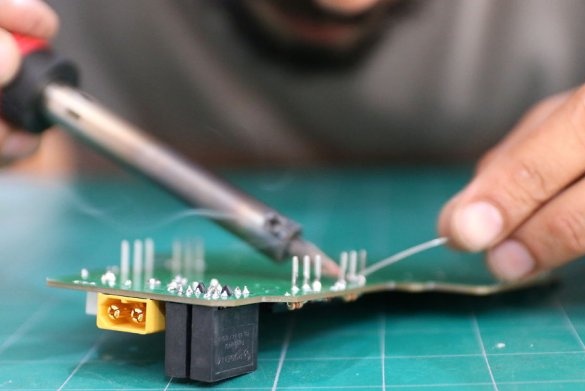

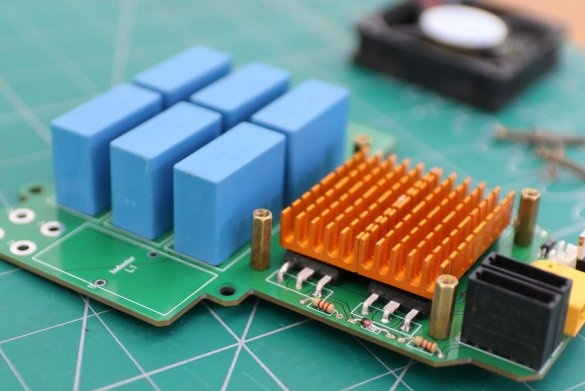

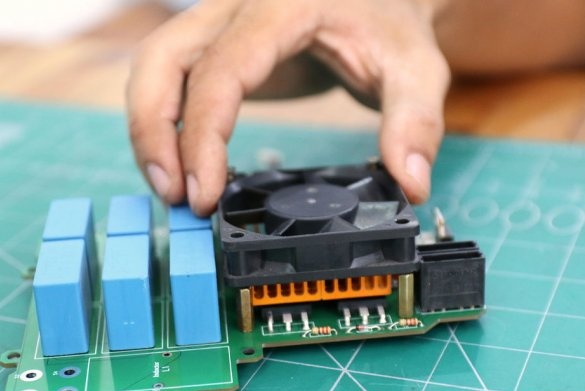

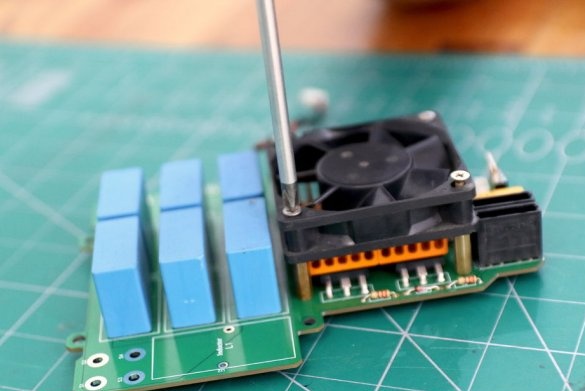

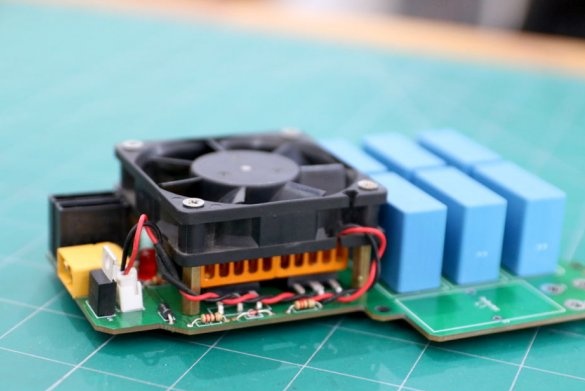

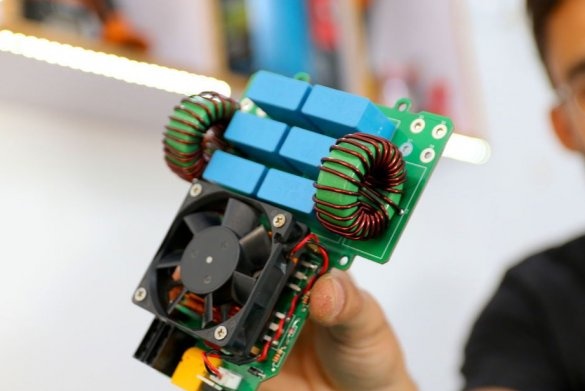

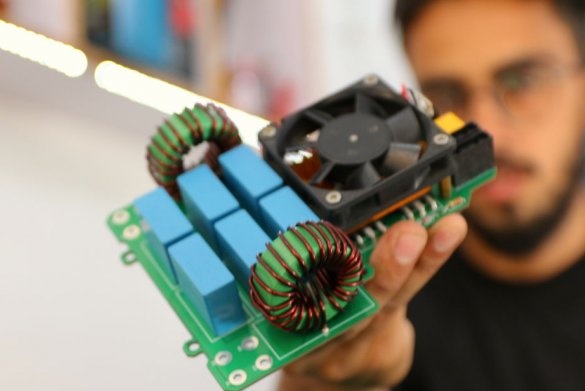

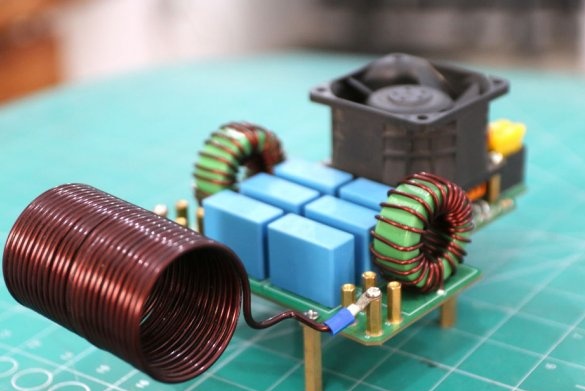

Step Three: PCB Mounting

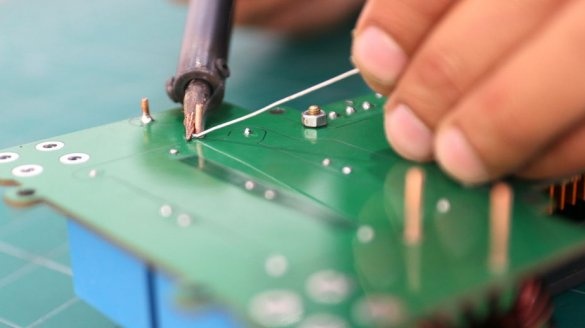

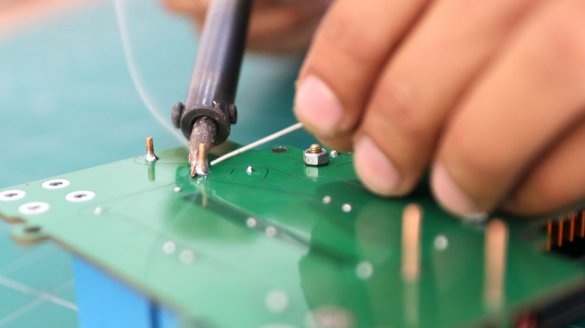

After all the details have been assembled, the master proceeds with the installation of the board.

It starts with smaller parts - resistors, diodes, connectors.

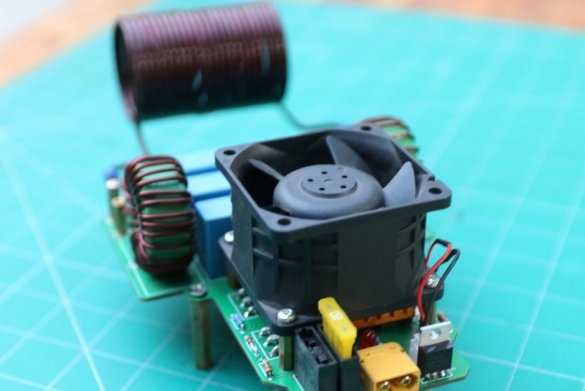

Installs a radiator and fan.

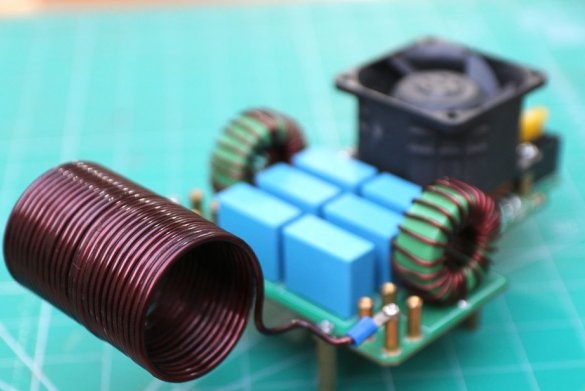

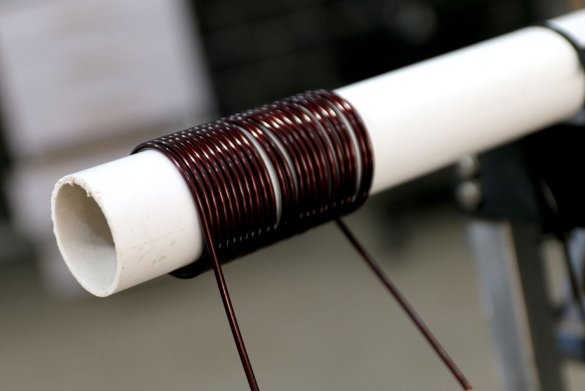

Step Four: Inductor

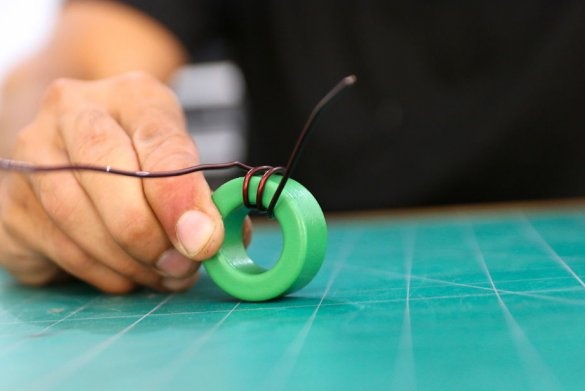

Coils master makes of 24 mm ferrite. The winding is wound with 16 AWG copper wire. It is necessary to wind 22 turns.

Then solder and to the board.

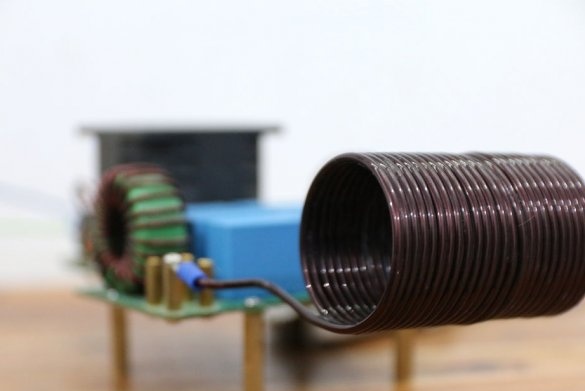

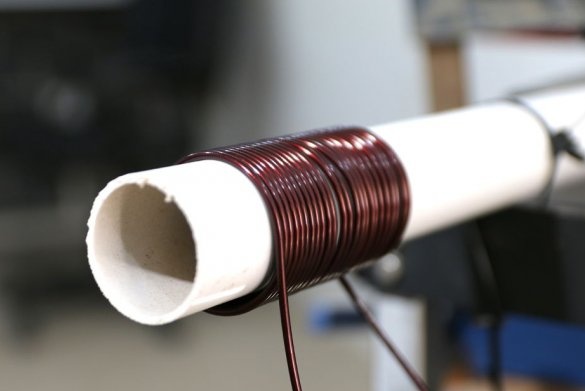

Step Five: Induction Coil

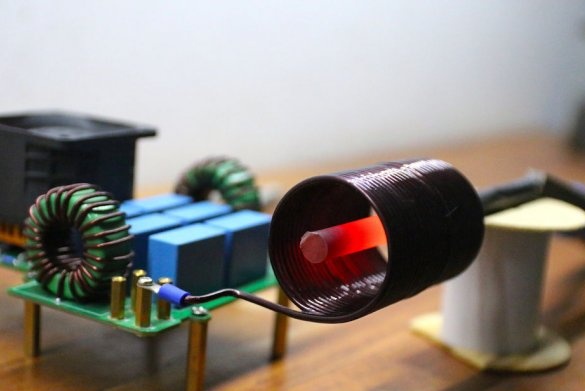

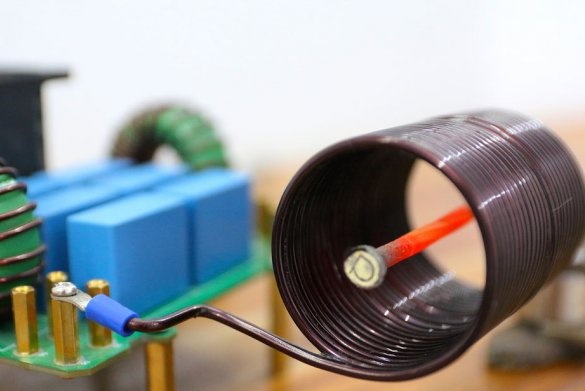

Induction coil wound from 12 AWG copper wire. Produces winding on a plastic pipe. The number of turns 25. Mounts the terminals at the ends.Mounts the coil on a circuit board.

All is ready. Tests have shown that a metal ruler and a 5-mm metal rod are heated to red in a few seconds.

The whole process of manufacturing such a device can be seen in the video.