I welcome all fans to craft, I propose to consider instructions for the manufacture of a powerful and convenient drilling machine do it yourself. The author decided to install a drive from the washing machine on the machine, as a result of which the speed is reduced, and the torque increases. The machine easily drills thick sheet steel with large diameter drills.

A carriage rides along the rack in a vertical direction, on which all equipment is fixed, the carriage is tightened, as a result of which the backlash is removed. The author has made the giving mechanism from bicycle details. If the project interests you, I propose to study it in more detail!

Materials and tools used by the author:

Material List:

- bearings for the carriage;

- threaded rods, nuts, washers;

- a straight profile pipe for a rack;

- profile pipes for the base;

- springs;

- motor from the washing machine and belt drive;

- drill chuck;

- round pipe and bearings;

- switch, wiring.

Tool List:

- grinder;

- welding machine;

- vise;

- drill;

- tools for threading;

- tape measure, marker;

- paint for metal.

Manufacturing process homemade:

Step one. Putting the foundation together

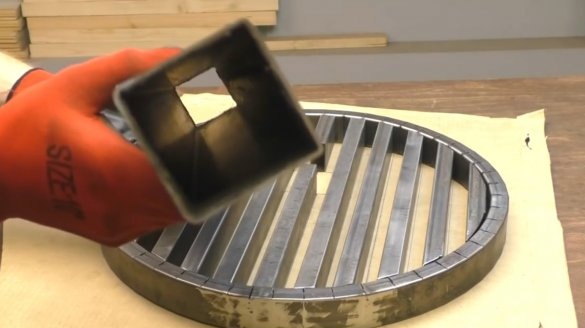

First of all, we collect the base, the easiest way is to make it rectangular, but the author decided to make the base in the form of a circle. First, draw a circle, and then cut the pieces of pipes that will be laid in this circle.

At the end, we bend the profile pipe into a circle and weld everything well. To bend the pipe into a circle, we make rows of cuts in it with a grinder, they should be at the same distance from each other.

Step Two Rack

We prepare and weld the stand to the base, it should be clearly vertical. We strengthen the rack by cutting a triangle from the pipe or other details. Of course, we clean the pipe stand well from rust and initially check that the pipe is flat.

Step Three Carriage

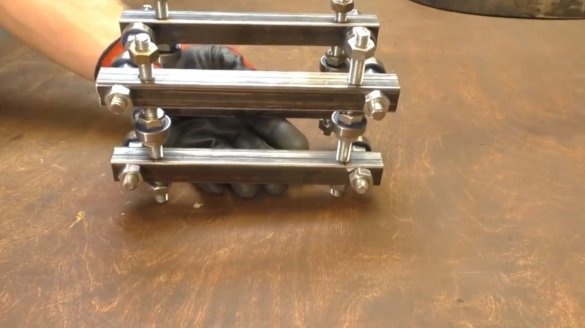

Let's make a carriage that will move along the rack.The carriage is made of profile pipes, threaded rods and bearings that work as rollers. The whole thing is pulled together with nuts and washers. We tighten the carriage on the stand, as a result, the bearings are pressed tightly against the pipe, and there are practically no backlashes.

At the end, we make mountings for the motor from a steel plate. The holes must be oval so that the motor can be moved away, thereby pulling the belt.

Step Four Working axis with chuck

First of all, we will make a sleeve for the axis, for this you need a piece of a round pipe, we press bearings into it, for durability it is better to put two bearings on each side.

The author uses a threaded rod as an axis, twist on the axis two nuts on each side, as a result, an emphasis is obtained. Having inserted the axis in its place, we weld the bearings from above with washers and process the welding with a grinder.

The manufactured sleeve is strictly welded to the carriage at right angles. That's all, now on the one hand we put a pulley on the axis, and on the other hand we install a drill chuck. Before the final installation, we check with a square from different sides, so that the drill stands strictly perpendicular to the base.

Step Five Feed unit

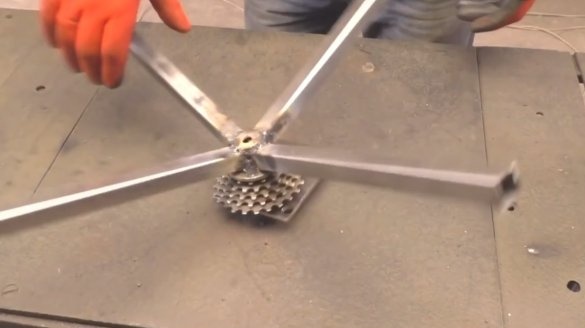

We make a supply unit, for this we take a block with bicycle sprockets and make an axis under it, as a result, the sprockets should rotate freely on the axis. The axis is welded to the plate, and the plate is attached to the carriage. We weld a handle to the sprocket block itself, which can be welded from profile pipes.

We install the chain from the bicycle, on the basis of a simple clamp for the chain. We are trying to work, we choose the optimal asterisk for ourselves, so that it would be easy and comfortable to work on the machine.

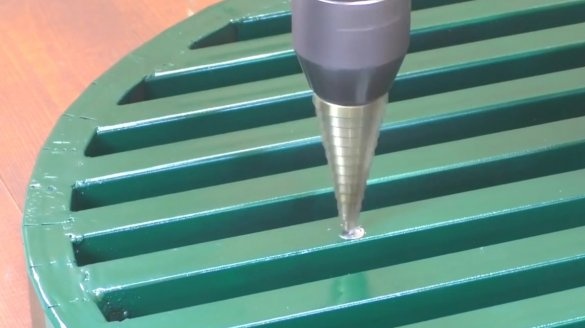

Step Six Final touches and tests

We put the switch in an accessible place, paint the machine, that's all, after that the machine can be tested. To demonstrate the work, the author drills a rather thick sheet steel using large diameter drills. Torque is more than enough, which was required to prove. If the speed is insufficient, one more small pulley can be placed on the driven axle.

The project is completed on this, I hope you liked the homemade work, and you found useful thoughts for yourself. Good luck and creative inspiration, if you decide to repeat this. Do not forget to share your ideas and homemade things with us!