In the last article "Band-grinding machine from angle grinder on three rollers" A master from Finland told how to expand the functionality of angle grinders. In this article, the wizard presents a similar devicebut on two rollers.

Let's see it at work.

To make the fixture, the master used the following

Tools and materials:

- Sheet metal 3 and 1.5 mm;

-Drilling machine;

-Bending machine;

-Bearings;

-Vise;

-Welding machine;

-Fasteners;

-Hammer;

-Ushm;

-Tap;

-File;

-Milling machine for metal;

-Spring;

- A roller from a skateboard;

- Clamps;

-Press;

-Marker;

-Roulette;

Step One: Mounting Plate

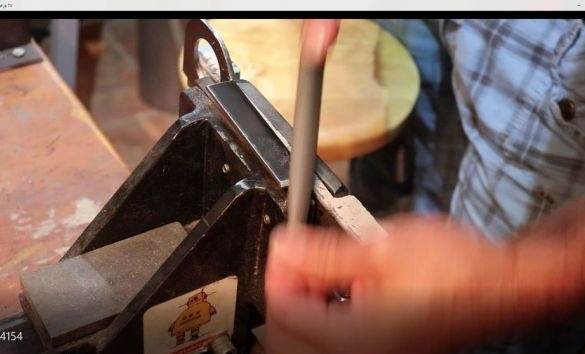

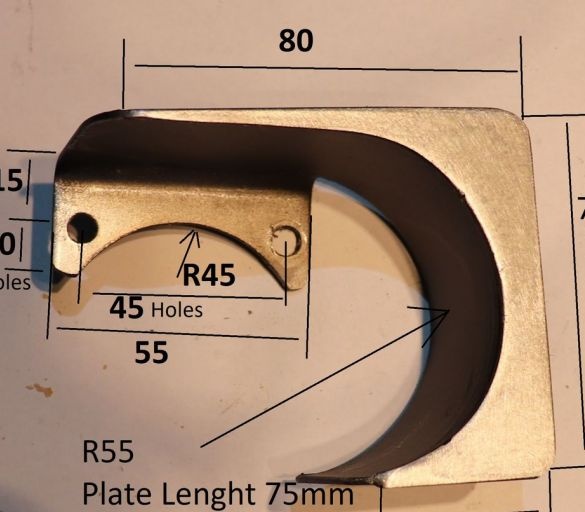

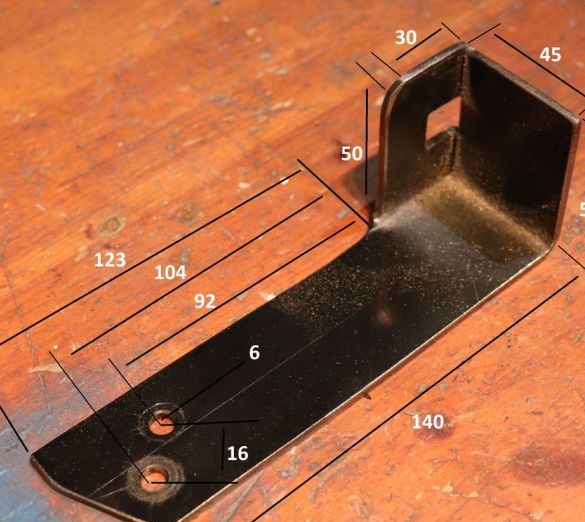

The master made the mounting plate from 3 mm sheet metal. Plate length 150 mm. Width 50 mm wide and 30 mm narrow end of the plate. In the plate, the master makes a hole for installing the mounting of the angle grinder. One edge of the plate bends. Bend size 20 * 90 mm.

The master processes the mounting hole with a milling cutter, and then forms the teeth with a file. The diameter of the hole welds the ring. The mounting plate is installed instead of the protective cover.

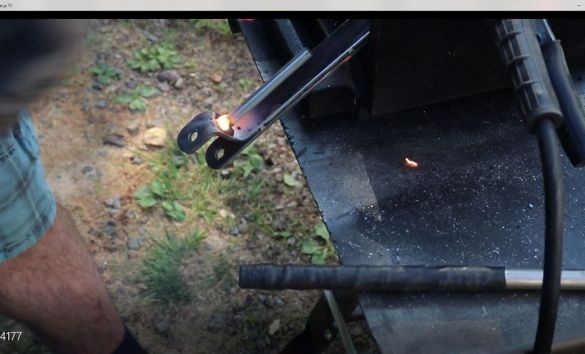

Step Two: Tension Mechanism

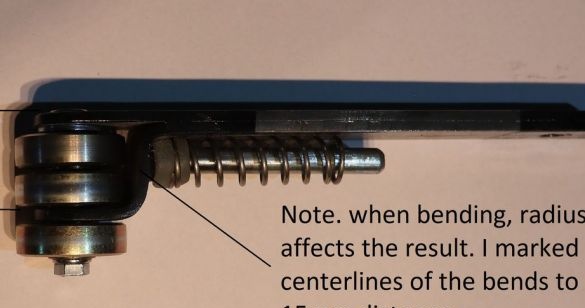

The tension consists of two plates welded together (one straight line, the second L-shaped) and a guide welded to the mounting plate. The tension plates are inserted into the guide. A rod is welded to the plate, and to a guide sleeve. A spring is put on the rod and the plate is mounted on the guide.

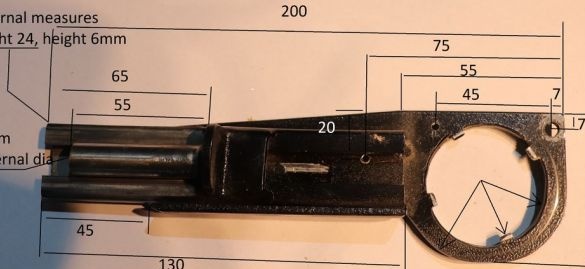

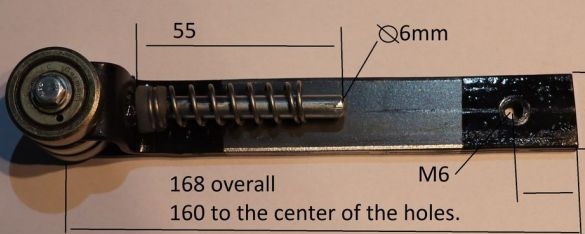

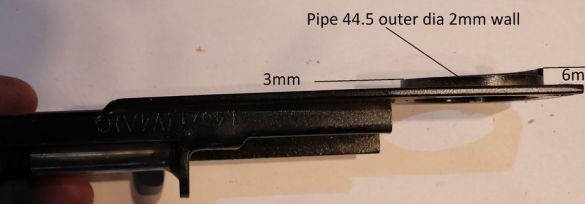

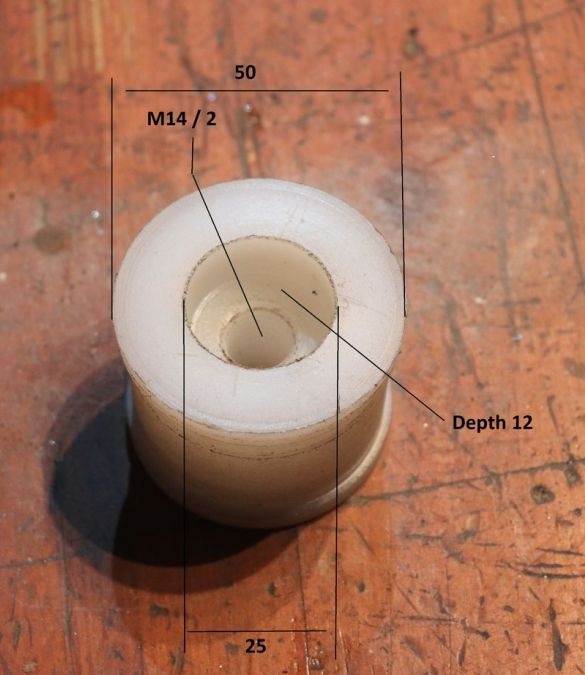

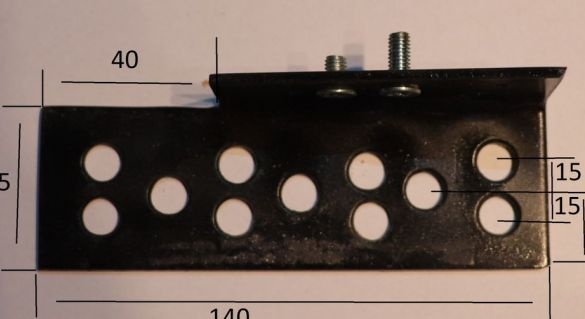

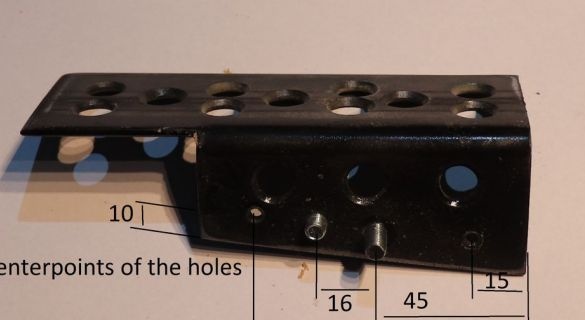

Photos with the size of the device.

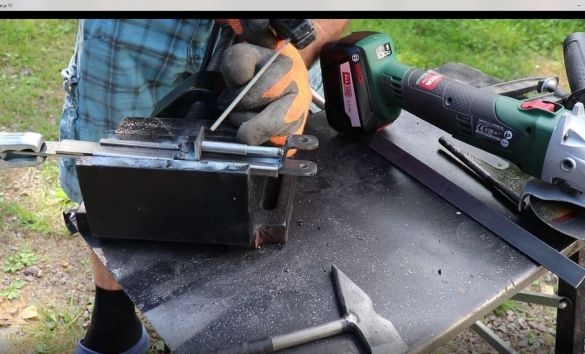

Step Three: Mount

For quick installation and removal of the fixture, the master makes the mount in the form of two spring-loaded latches. The latches are screwed onto the screws of the gearbox cover.

Step Four: Bearings

In the upper part of the plate, the master installs thrust bearings.

Step Five: Roller

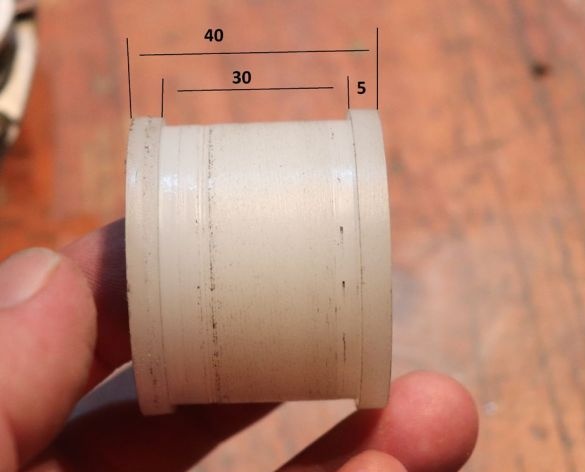

First, the master installed a roller from a skateboard on the shaft of the UShMki, then replaced it with a plastic pulley.

Step Six: Protective Cover and

Makes a protective casing.

Seventh step: plate

Makes and installs a perforated plate to reduce friction of the sanding belt.

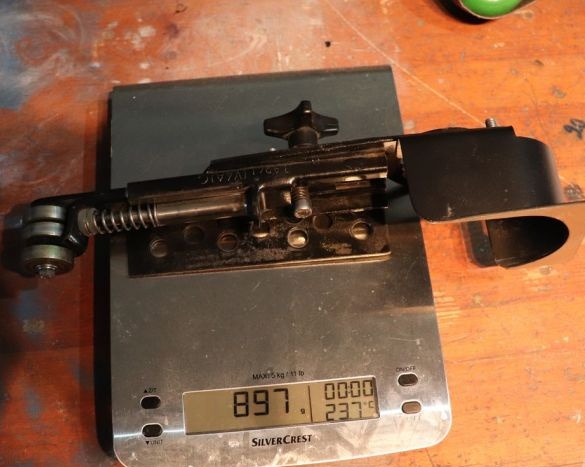

Step Eight: Table Mount

From a clamp and a metal plate, it makes a mount for installing a belt sander on a table.

Belt-grinding device for angle grinder is ready.

In the video, you can see in the work a two-roller and three-roller device,

as well as the manufacturing process.