Many people need a lathe. It allows you to process different materials, and shape the cuts and blanks. The market offers lathes of various sizes - from small to bulky. However, the best quality of the machine can be guaranteed only when you do it yourself, so now we will consider how to make a small lathe using a hand-held electric drill.

We make a mini lathe from a drill in the video:

[media = http: //www.youtube.com/watch? v = SDKKwm2dSG8]

So, for starters, we need a piece of plywood, to which you need to glue two wooden blocks in advance to get something similar to a table, then a drill, which should have a handle, or another home-made mount, a workpiece for testing the operation of the machine (in our case, foam) , two types of sandpaper - small and large, as well as two wooden blocks.

The first thing we have to do is mount for the drill. Therefore, it is necessary to put the drill on a table, that is, on a piece of plywood, circle with a marker, make a hole for the bolt on the top of the handle. You should pay attention to the fact that the drill must stand upside down, and this is necessary so that the tool does not overheat, because the drill has ribs on the sides and bottom for cooling. In order to fix the drill, you just need to remove the handle bolt, pass it through the hole on the plywood and fix the handle back.

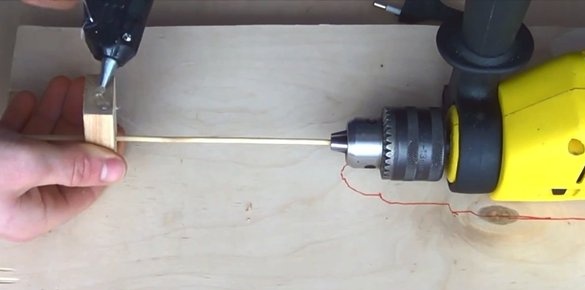

Next, we have to manufacture the rear beam of our machine. To do this, we need a wooden block and a small diameter drill (a little more than a barbecue skewer). We drill a hole on the bar, fasten the skewer instead of the drill on the drill, draw the bar through it and fix it on plywood with hot-melt adhesive.

It remains to take care of the next part of the machine, which will allow us to shape our workpieces. For this we need a second bar and sandpaper. Just glue the paper on both sides of the bar.

The workpiece we want to process is put on a barbecue skewer. After that, it remains only to give free rein to imagination and to shape our blanks with emery papers of various sizes.

Thus, you can create your own mini lathe, which will be ideal for processing foam and small wooden blocks. The same technology can be used to create more powerful machines that can handle more serious materials.