So spring came, the need for garter material, in his yard or in the country, has increased greatly. On the Internet there are a lot of descriptions of home-made devices for dissolving plastic bottles on wonderful shrink ropes. All these devices have the same principle of operation, but a different type, material and method of manufacture.

Video: Test, the width of the resulting lace is 2 mm.

I also decided to repeat one of the most successful and simple, in my opinion, options, but unfortunately for some reason his work did not suit me, the thread was constantly torn, the cutting width swam. I had to modify the design for myself, having obtained the desired result of the mechanism and, as a result, another option appeared for public viewing.

PARAGRAPH 1. List of necessary materials and tools.

1. Aluminum corner

2. Nail 200 mm., M6 die

3. Blade from a construction knife

4. Nuts, washers

5. Drill, drill d = 6 mm, d = 3 mm

6. Bulgarian

7. File, file, sandpaper.

Point 2. Manufacture.

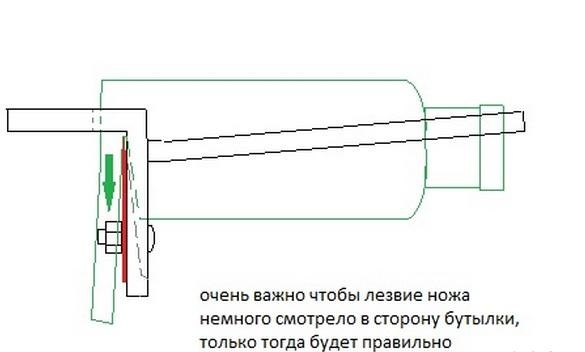

Scheme: Fundamental.

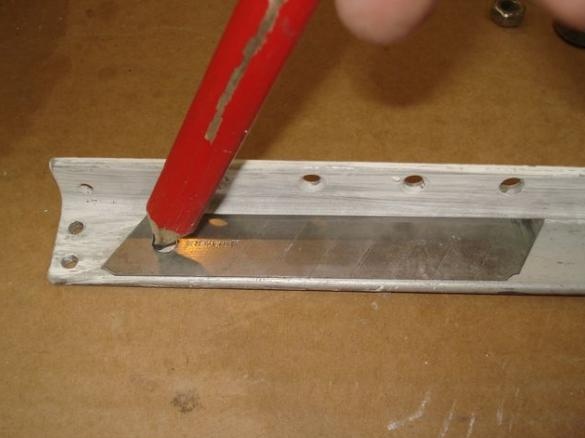

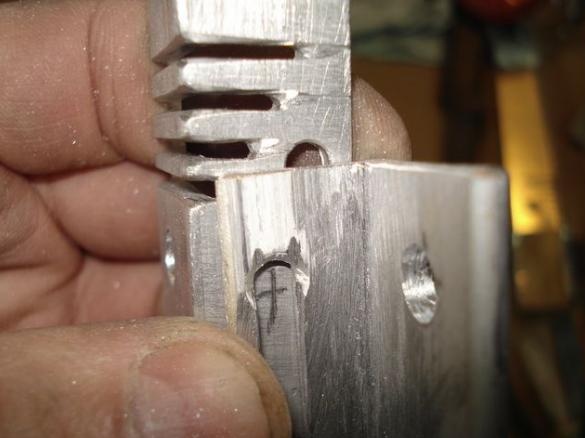

We attach the blade to the corner, sharpening it right into the corner, mark the drilling point under the mounting hole.

Mark the cut line.

We drill a hole d = 6 mm. and saw off the workpiece.

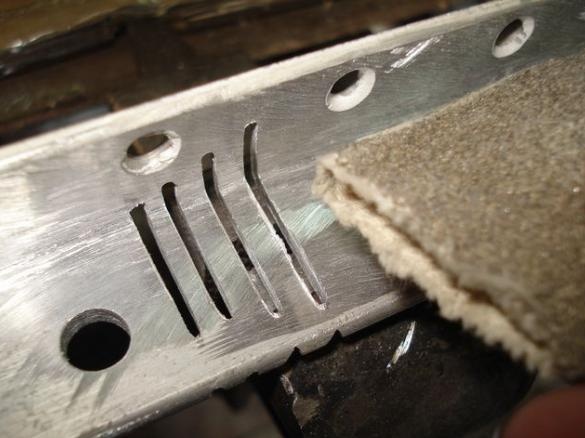

We make markings for the cuts with a step of 5 mm from the edge of the hole.

We saw it with a saw for metal or immediately with a grinder (a disk 1-1.2 mm thick). On one side of the corner, the cuts should correspond to the dimensions of the expected (desired) cutting width of the future threads (ropes), in the photo are approximate sizes, each makes for itself. On the other side, the gash is done almost to the full width of the corner, we leave 1-2 mm. jumpers.

Grinder finish the slot.

It is very important to handle everything with a file and sandpaper, so that there is not the slightest hook during broaching the thread.

Round all corners.

A hard metal brush removes the chips well.

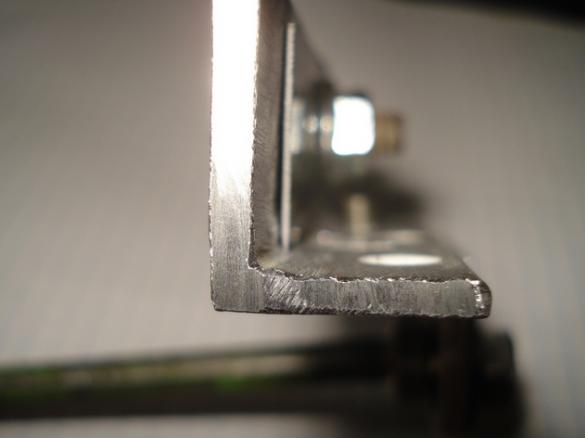

In the diagram: It is advisable to use a grinder to remove the fillet inside the corner so that the blade abuts against the wall, and not the fillet.

View of the corner to the groove.

View after fillet rounding.

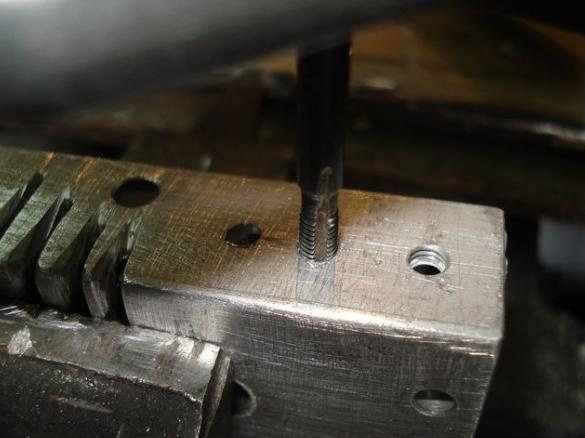

Let's make an axis from a nail of two hundred, its diameter is 6 mm. We cut 15-20 mm. M6 threads.

Sharpen the tip without removing the die.

Immediately fix the damaged thread.

IMPORTANT - bend the axis a little, this should set the angle of cut and at the same time automatically feed the bottle.

If the thread does not enter the hole of the knife, then you can sharpen the thread a little.

Or bore a little hole in the knife, with a homemade drill with sandpaper.

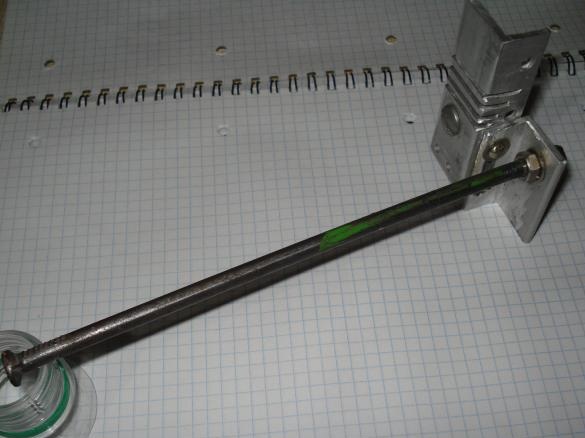

Everything went well, set the stud with washers in place. We fix the mechanism in a vice.

Done.

POINT 2. Check in work.

The result was unsatisfactory, the thickness of the obtained thread is constantly changing, and as a result, a frequent break.

The reason for this, I think, is a slightly incorrect angle of attack of the knife, if you put 0.1-0.2 mm. lining behind the blade, then when cutting the thread, the bottle material will itself ask for a knife, and not try to get off it.

But I did not go the easy way and redid the mechanism for feeding the bottle to the cut.

If everything worked out right away, everything cuts perfectly, then congratulations. For those who have problems, read on.

POINT 3. Revision.

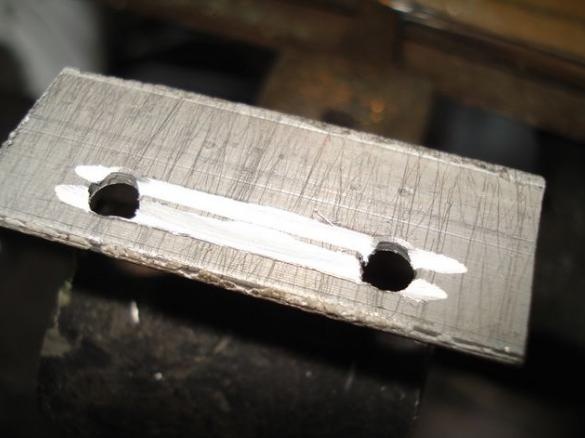

We saw off a corner 45 mm long.

We drill two holes d = 4 mm. We outline the cut lines.

A grinder, on both sides, cut out the middle.

We process a file, a file of the edge.

We mark a hole for the stud.

We drill D = 6 mm.

We outline the holes for the two M4 bolts.

We select the appropriate two bolts.

We drill holes with a drill d = 3 mm.

Cut the M4 thread.

We try on how everything fit. Now you can make adjustments, depending on the intended width of the rope, adjust the axis with the bottle there.

At first I tried to decorate the Axis in this way, but then I didn’t like it, I removed it.

Set the axis in place. To cut a whole bottle, 30 cm are put on the axis. A metal-plastic pipe d = 15 mm. (seen in the video), if there is a desire to dissolve the neck, it is necessary to remove the pipe so that the axis does not pinch the neck of the bottle.

Everything turned out, you can check.

ITEM 4. We make a rope of 2 mm.

Now all is well.