So for homemade we will need: beaten CD drive or motors from it, an empty box from CD / DVD discs, silicone sealant, GOI paste, gasoline, a piece of foam rubber, any TsIATIM grease or solid oil.

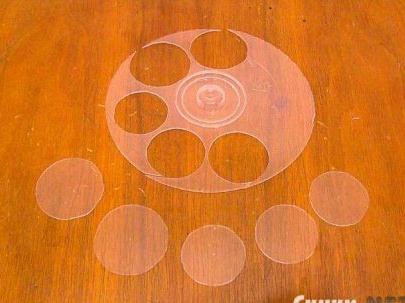

From the foam rubber we cut out a circle with a diameter equal to the distance to the place for recording CD data.

We are preparing a polishing compound. In a small container, chop the GOI paste and wet it with gasoline. After we add sealant. Correlation: for one part of sealant - two parts of GOI paste. If the composition is too thick, it can be diluted with gasoline. The resulting paste is applied to the foam rubber circle and let it harden. By the way, in this way you can do polishing for manual polishing.

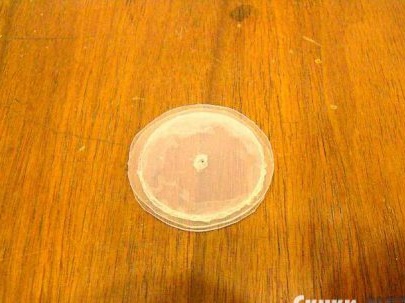

We prepare the substrate on which the patient will rest. It is necessary in order to protect the reverse side of the disk. For this, a disk without a coating is suitable, it is used as a packaging one. Apply and spread sealant on this disk. Before applying sealant, the disk must be sanded, it will be better to hold. The back of the disc and the bottom of the box must be rubbed with grease and wiped dry. If grease remains, it will slow down the rotation.

From any plastic, for example from the second cover, we make a roller. We cut four circles: two with a diameter under the foam rubber circle, and two 2 mm smaller.

Glue them together.

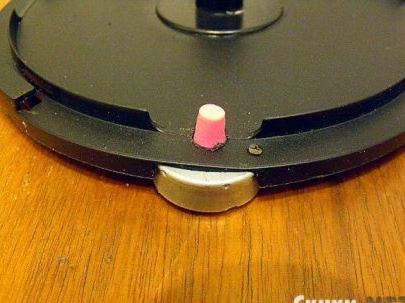

At the bottom of the box, cut holes for the motor and drive roller. The clip is made from an eraser. Not every eraser will do. There are erasers that crumble. If you can pinch off a piece from it with your fingernail, then it will not work. Ideal is the old Soviet "Architect".

We mount the second motor on the box lid.We also install a roller from plastic circles on the screw. Glue foam rubber with GOI paste on top of the roller.

All. Super useful device is ready. Set the substrate down, CD / DVD disc, a shiny layer to the top. Lightly moisten with water and start. The motors are connected to a universal power supply. Despite the fact that they are designed for 6 volts, you can safely set 9. Otherwise, they will spin slowly. It took me about 4 minutes to polish one disc, even with deep scratches.

In the future, I slightly improved the wetting system. To do this, the foam rubber circle was perforated with a needle on the side of the polishing surface, and from the top, right through the cover and the roller, I drilled a hole to the foam. For wetting, the holes on the lid and the roller are combined, and water is poured from the nose drop bottle.