I noticed that with a small opening of the throttle, gasoline flows out of the sprayer in a stream, that is, fuel is not sprayed due to too low air flow rate. And this is a brutal overspending, failures, and the toxicity is very high, since the fuel burns badly.

The problem arose, how to turn gasoline into gas at the outlet of the atomizer? There are already improved sprayers, but they do not inspire confidence in me. There was an idea to heat the atomizer so that the gas in it instantly turns into steam (gas). Still logical? I think from this modernization the quality of the mixture will be many times better.

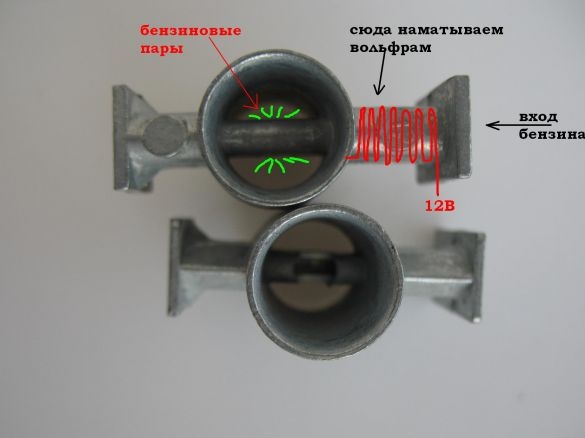

How to make a spray heater? Very simple. You will need fiberglass (or any other insulator that does not burn), as well as epoxy. As a heating element, a tungsten wire (can be found in old heating elements).

First, we take fiberglass and wrap the channel through which gasoline flows on the sprayer. Then we wind the wire over the fiber with a spiral, in the end we fix the whole thing from above with epoxy resin or cold welding. We connect one end of the wire to ground, and plus 12 V through the fuse to the other end.

You can also put the switch in the cabin so that you can turn on / off the heater and feel the difference.

The length of the wire, think of a way to connect it yourself. This is just an idea)