Introduction

Well-lubricated motor bearings, plus a massive emery stone contribute to long rotation after shutdown. And if the device is two-way, and in another place, say, an iron-based diamond wheel, then it can rotate for about five minutes until it stops. Mechanical braking is fraught with dangers, additional debris and useless wear of the tool. He will save us from all these troubles electronic brake, according to an extremely simple scheme.

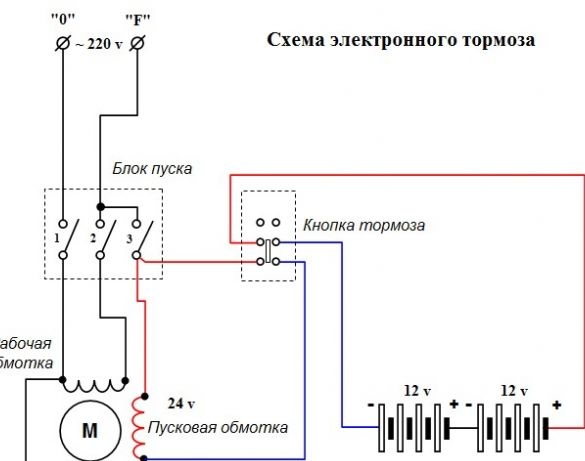

Practice shows that if 24 volts of direct voltage are applied to the starting winding of the motor, then the emery stops in a matter of seconds.

Materials and Tools

- P-2K switch without lock

- Two gel 12-volt batteries of 6-7 amperes from the uninterruptible power supply unit for a stationary computer

- Electric 2-wire wire with a cross section of at least 1.5 square meters. mm

- Drill with a diameter of 10 mm.

- Drill with a diameter of 3 mm.

- screwdriver

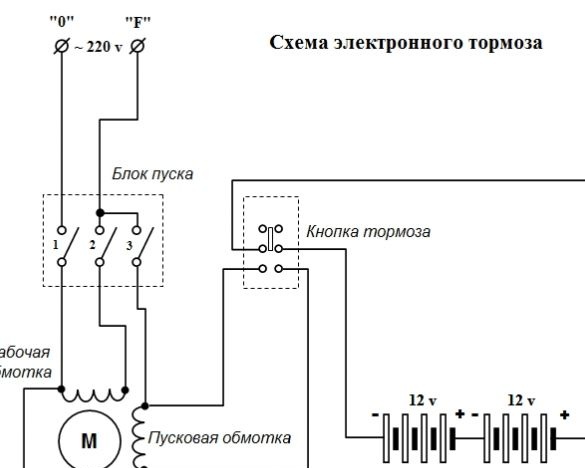

- soldering iron

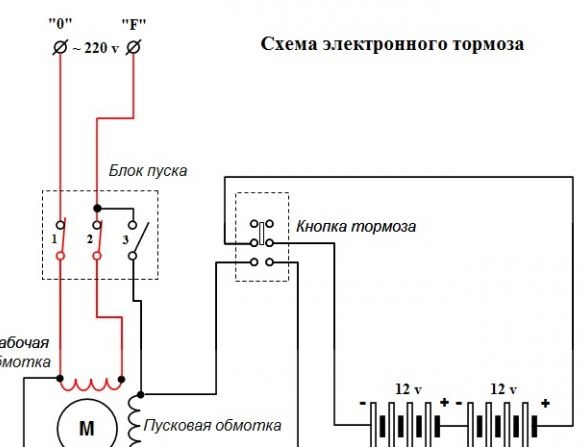

Step 1. We take out the starter unit and determine the conclusions of the working winding. In the diagram, they are connected to contacts 1 and 2. Visually, they can be defined as follows: when you release the black "Start" button, the contacts that remain closed - the working winding is connected to them. The other two wires are the launcher, one of which is connected to pin 3, which closes only when the button is pressed. When you release the button, it opens. The current flows as in the diagram (in red).

Step 2. We drill holes with a diameter of 10 mm. and two of 3 mm. for mounting the P-2K switch in a place convenient for us. We solder the wires according to the scheme and fix it on the case. I made a protective device against accidental pressing (show your creative imagination). We make all the connections according to the scheme. The polarity of connecting the batteries to the motor winding in this device does not matter.

Step 3. Check the operation of the circuit. Manually “twist” the emery, press the brake button. He must stop immediately. The first connection to the network ~ 220 v after alteration is recommended to be done through a type 47 VA automatic machine at 6 amps. In case of a connection error, it should work.

Conclusion

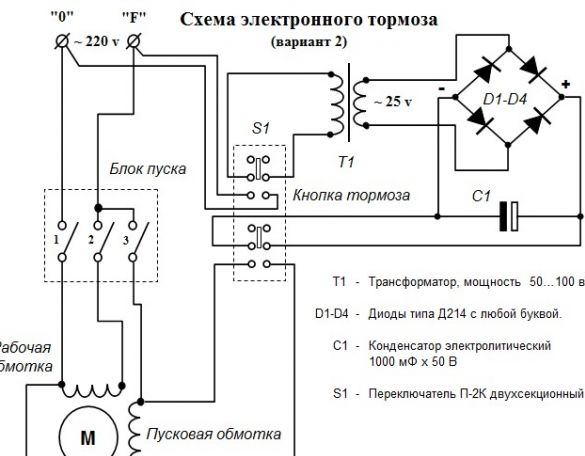

In addition to the described, you can use another option: with a power supply of ~ 220 v from the network, which I made to my friend according to the above diagram.

Here, instead of the batteries, the simplest transformer rectifier with a voltage on the secondary winding of ~ 25 v is used. Switch P-2K - two-section without a clamp. Diodes can be used without radiators, as they work in short-term mode.

Video of the electronic brake: