Many harvest fruits and berries grown in summer houses, preserving them, however, the author of this device was more interested in drying berries and fruits for their further storage. In order to make the drying process more efficient and less energy intensive, the author decided to manufacture a dehydrator based on solar energy.

Materials that were used by the author to create a device for drying supplies:

1) wooden blocks 50x40 mm and 40x40 mm

2) moisture resistant plywood

3) slats 20x30 mm

4) mosquito net

5) black paint

6) glass

7) cans

8) antiseptic

9) mineral wool insulation

Let us consider in more detail the design of this dehydrator, as well as the main stages of its construction.

To begin with, the author got acquainted with sites on the use of alternative energy. On them, he found many different designs of solar dehydrators. Before choosing the right one for his needs model of the solar dryer, which he will be able to assemble himself, the author also looked at several videos on YouTube, where they showed in detail the main pros and cons of each dehydrator model. Thanks to the information collected, the author found out that almost everything can be dried in a dehydrator: fruits, vegetables, herbs, tea leaves, berries and even crafts from clay. Therefore, he decided to build such a convenient thing for his needs.

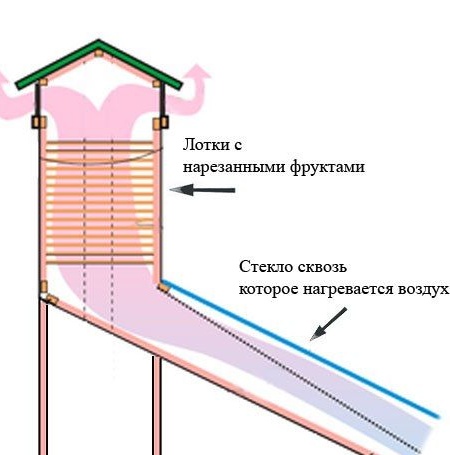

The creation of such a device does not require special skills or knowledge, it is quite simple to use. The main feature of the model of this dehydrator is that it fully works due to solar energy and thermal induction. the dehydrator itself consists of two main chambers, a drying chamber, where supplies are dried on trays, and a solar collector, where air is heated.

After the author decided on the model of the dryer and prepared the necessary materials, he proceeded to its immediate construction. The main frame of the solar dryer consists of wooden blocks hammered into a rectangular frame. The author used bars measuring 50 by 40 mm and 40 by 40 mm. The width, length and height of the frame is chosen at your discretion, however, the standard width of the dehydrator is somewhere around 50-60 cm, and the height is 200-220 cm. Such parameters make it convenient to use, and at the same time dry a large number of products at once.

Then, the frame was sheathed with plywood sheets outside, it is best to use moisture-proof plywood so that the dehydrator lasts as long as possible.

Inside the resulting box, which will be a drying chamber for products, the author made a number of racks, on which trays with supplies will later be installed. The distance from the tray to the tray should be about 70 mm. The trays themselves are also made of slats on which a mosquito net is stretched. For shelves, wooden blocks of 20 by 30 mm in size are perfect.

All this allows air to circulate freely between trays and evenly dry supplies.

Behind the drying chamber, the author made a door with lapel fastenings from the bottom, which leans down. In order for it not to swing open on its own, he made standard fastening fastenings on the sides. So that the frames can be folded onto the door, before installing them in the dehydrator, or when already dried up supplies are obtained, the author attached chains to the sides of the door. These chains help keep the door level and relieve stress on the hinges.

Further, the author began to make a chamber for heating the air from sunlight. In fact, this is a standard solar collector.

His frame was made of the same bars that the author used for the frame of the drying chamber. Inside the resulting box, the author installed a design of cans with a drilled bottom. The author glued these cans in such a way as to produce peculiar metal tubes, which were then painted with black heat-resistant paint. The air heating chamber was covered with glass above, and insulated with mineral wool from below. The sun's rays passing through the glass will heat the tubes, which in turn will heat the air inside and outside.

Then both chambers of the dehydrator were connected into a single unit. In order for the air to circulate, holes are made at the bottom of the heating chamber through which air will enter the dehydrator, and holes are made at the top of the drying chamber through which air will leave the dryer space. Thus, hot air will pass through the products, drying them and taking away excess moisture with them, and from the bottom, cold air will be absorbed into the heating chamber.

There are dehydrator models where the speed and amount of air passing is controlled by incubator regulators and fans, but these are more complex models, since they require the installation of solar panels to power the electronics.