Noticing interest in my previous article, I decided to share ideas. First article.

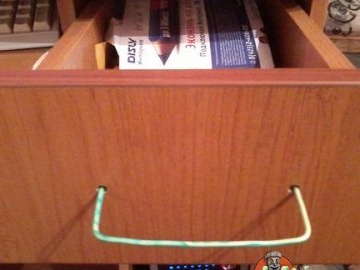

The handle for a box.

A long time ago a pen broke on my desk. It didn’t cause much discomfort to me, I just picked up the box from the bottom. This method is not always possible, therefore, for example, I decided to make a handle for this box, for others the technology will be similar.

The distance between the holes is 10 cm, the thickness of the front wall is 3 cm, the reach for the hand is 3 cm, the limiter is 2 cm (can be varied).

Based on these sizes, the minimum wire length is 10+ (3 + 3 + 2) x2 = 26 cm. (I got a piece of 32 cm and a cross section of 2.5 mm2, I made an excess length limiter).

Procedure:

1) search for a wire of sufficient length and alignment;

2) from the entire length we subtract the distance between the holes, divide in half, and postponing this distance from the end, make a bend at a right angle;

3) we try on the spot, inserting into one hole, specify the place of the second bend, produce it, we get a U-shaped blank;

4) insert the workpiece into the holes, but not all the way, you need to leave space for the handle to grab, make stops, bending the ends inside the box.

As you can see, there’s nothing complicated, I managed in no more than 5 minutes. The simplest method is described, you can change it, I make more beautiful options.

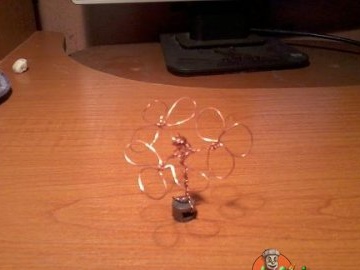

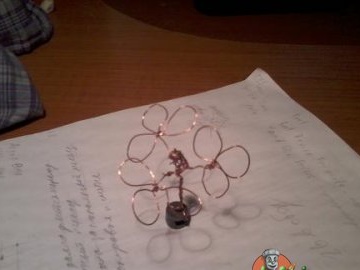

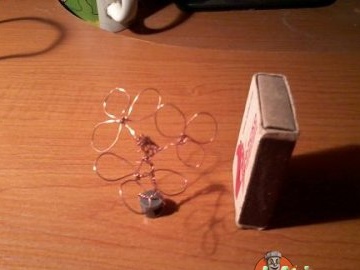

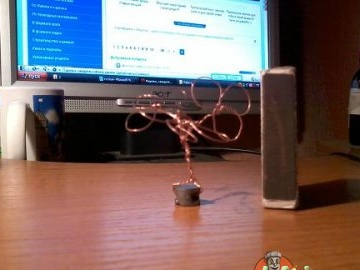

A flower made of wire.

It was sad, I wanted to make something subtle, elegant. I remembered how I made a flower, in the manner of chamomile, I wanted to create a miniature analogue (the prototype was about 10 cm in diameter by 12 cm in leg). I found a wire, a loose flexible wire, 17 cm. It was unusual to work with such a small size, but "my eyes are afraid, but my hands are doing."

For manufacturing, I needed 5 veins and 1 lead seal (I control access to the terminals of the electric meter with these).

From 3 veins I made petals, then I collected them on 1 vein-trunk. The barrel is attached by simple screwing. We bend the vein like the letter U, thread through the insides of the seal and twist.

I realized that the design is not stable enough, and added another core to the trunk, inserting it into the base on the other side and twisting along the trunk. Totally spent 10 minutes.

I suppose to try to combine with beads, I will demonstrate the result of intercourse on creation.

Adapter for battery terminals

Once I had a snag. It was necessary to start the car, and the wire terminals were larger than the battery terminals. Those who deal with cars know that there are big conclusions and fewer.

I solved the problem using wire. More precisely, a core with a cross section of 2.5 mm2, by winding on the terminals. The car started up and this design worked for a long time.

Bugs

Most often used in automotive electrics. Urgent temporary repair of fuses is carried out by winding the conductor on the horns (contacts). It is important to note that the task of the fuse is to prevent burnout of the wires, it must blow out before the wires begin to melt! By making a massive jumper, you run the risk of significant damage to the wiring, and even FIRE! Do not make more than one connecting core, and only in cases of burnout can the number be increased.

Hooks

My mother needed hooks today to hang the curtains. Asked, gave her a wire from his stock. I want to make a housekeeper out of wire, but until my hands reach, there is no urgent need.

If you need to get a thing out of the slot, then a long rigid wire with a hook bent end can help, a kind of integral - ∫.

Stiffness contour

The use of 2 and 3 core cables allows you to make very reliable designs, a variety of designs.

My example is the second life of a headlamp. I used pieces of VVG 3x4mm2 and VVG 3x4.5mm2 and a small piece of 2.5mm2.

The pike for the tester I mentioned in a previous article

The presence of interest, in the form of comments, will contribute to the continuation of this series.

More about the wire