Each of us was faced with the magic of soap bubbles. They fascinate us, make us dream and believe in miracles. How nice to watch when the breeze raises colorful bubbles into the sky. The author suggests that we make a machine for the production of soap bubbles, it is very easy to maintain and easy to manufacture. Using a soap bubble machine you can watch them for hours, and children will be delighted with it.

Tools and materials:

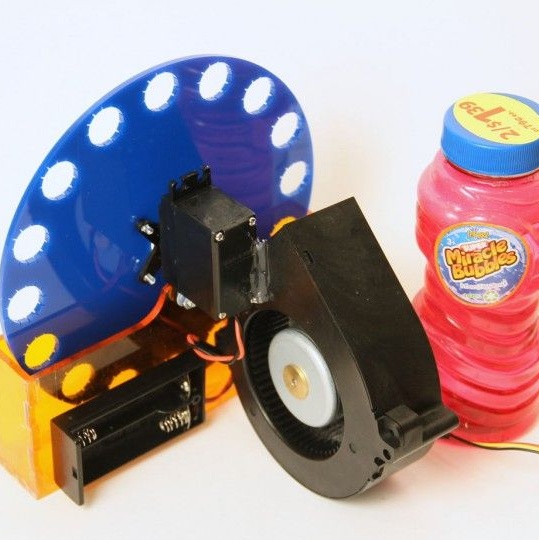

1. Tank for soapy liquid.

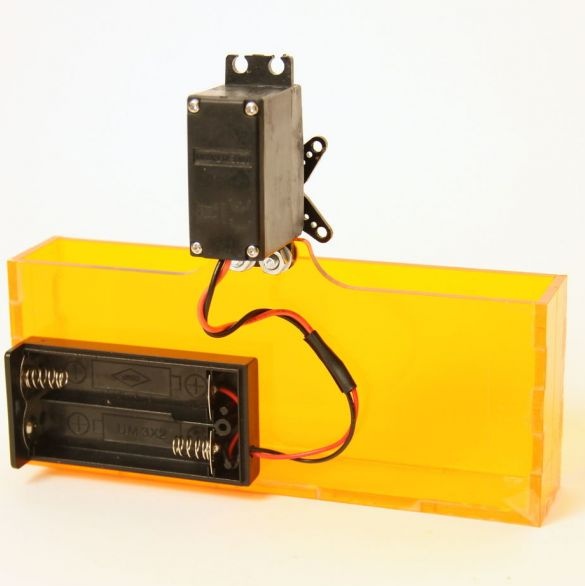

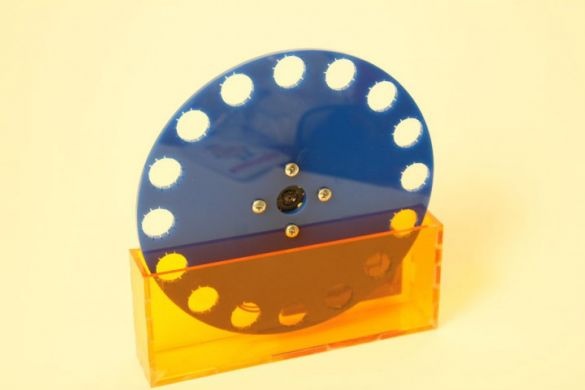

2. Wheel with holes.

3. Engine for wheel rotation.

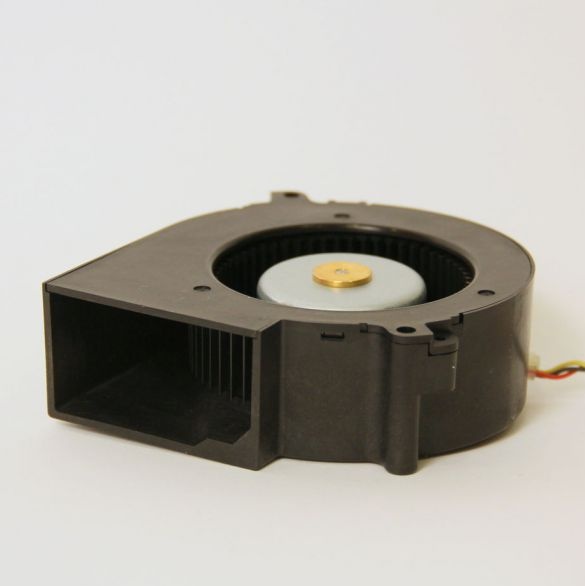

4. The fan.

5. Power supply for the fan.

6. Battery pack for the engine.

The author also used nuts, bolts, a glue gun, superglue to connect parts and an insulating tape to insulate the wires.

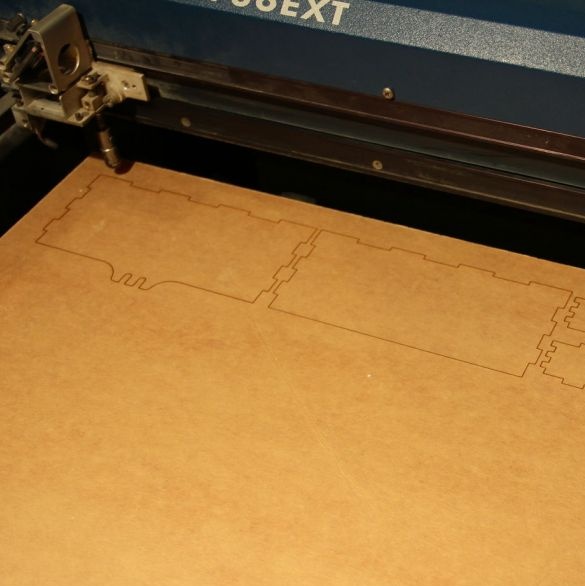

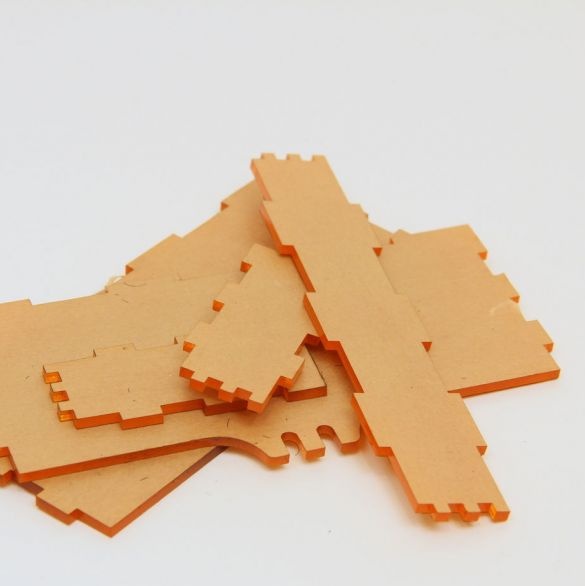

Step 1. Production of capacity

The author made a container from an acrylic sheet, 3 mm thick, cutting it out on a laser machine. Then he glued the parts with superglue and got a waterproof container for soapy water. As a replacement, you can use a plastic container of a suitable size.

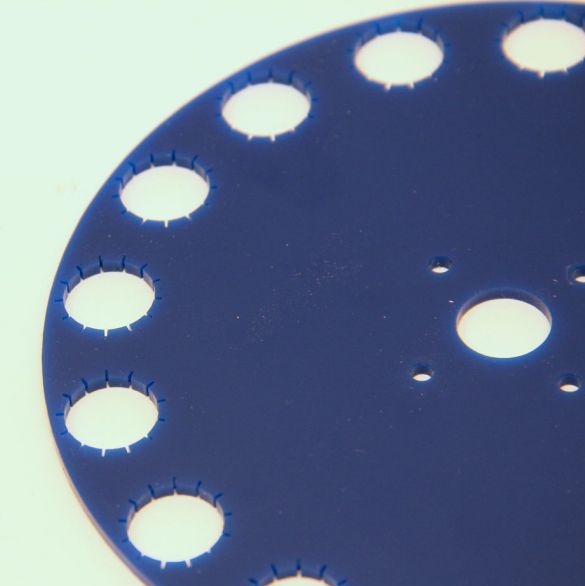

Step 2. The bubble wheel:

The wheel was also made by the author of acrylic using a laser cutter. Along the edges of the wheel are sixteen holes with a diameter of twenty millimeters. In the center is the hole for the motor shaft.

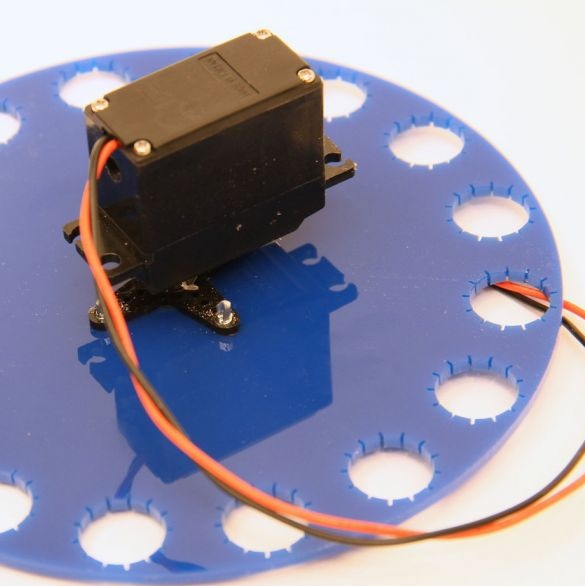

Step 3. Engine:

For this typewriter, the author specially selected an engine that would rotate slowly so that the fan had time to blow soap bubbles. He powered it from two batteries.

Step 4. Fan:

The author used a fan that runs on 12 V and with a nose to blow air into a specific area.

Step 5. Battery:

A 12 V battery was used to power the fan, and a battery pack for two AA batteries was used to power the engine.

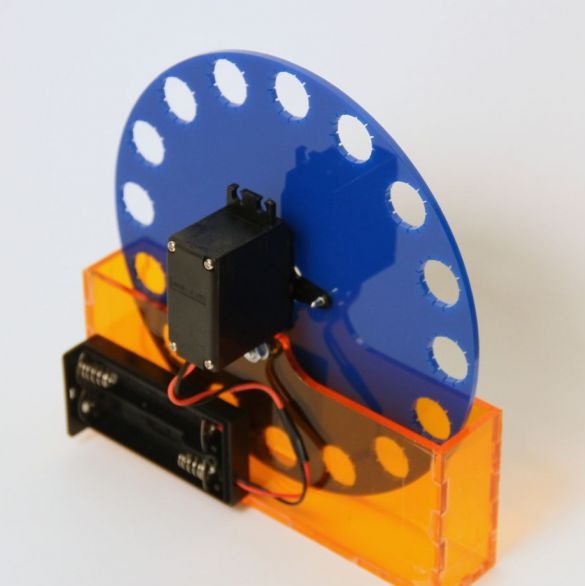

Step 6. Assembly:

The author attached the engine to the tank with two screws. Hot glue fixed the battery compartment, soldered the wires, insulated them.

The drum was attached to the engine with four bolts.

The fan installs behind the drum so that the air flow is blown directly to the holes. To supply power to the fan, a 12-volt battery from a screwdriver was used.

Step 7. Preparation of the solution:

To prepare the solution was taken water and dishwashing detergent in a ratio of 1 to 1.

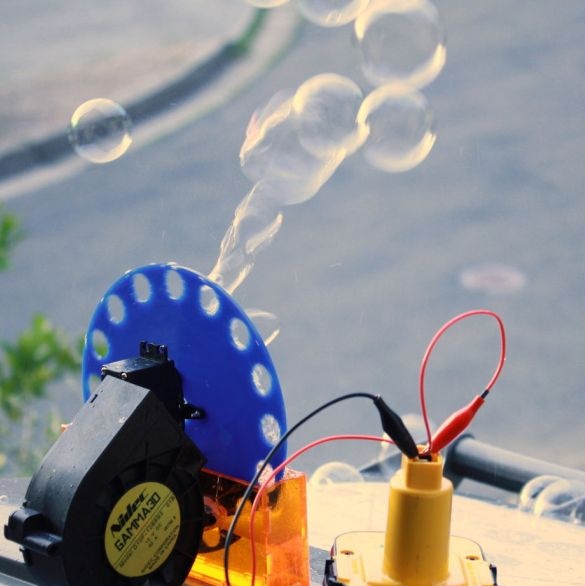

Step 8. Test the device:

After manufacturing, the machine was tested and showed excellent results.