Mostly the frames are assembled from a metal profile and a wooden beam, the latter option is the simplest, which is why our author chose it.

Also, under the frame building, you first need to choose the type of foundation, mainly screw piles and pouring a continuous reinforced concrete slab are used. In this case, the slab is selected, because there will be heavy loads on the floor, and so will be an excellent concrete floor for the car.

And so now let's look at all the stages of construction in detail, and also analyze what the author needed in such a difficult matter?

Materials

1. beam

2. fittings

3. roofing material

4. OSB

5. double-glazed window

6. loops

7.cement

8. sand

9. gravel

10. 30 mm board

11. professional flooring

12. insulation

13. isolation

14. nails

15. wood screws

16. metal corner

Instruments

1. concrete mixer

2. Bulgarian

3. drill

4. shovel

5. hammer

6. jigsaw

7. screwdriver

8. scissors for metal

9. roulette

10 level

11. corner

The process of building a frame garage do it yourself.

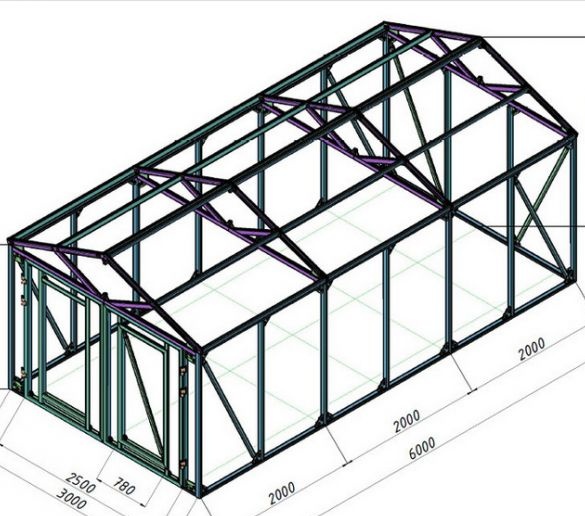

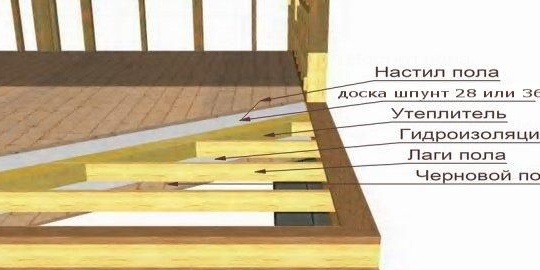

And so, the first thing the author gives us is to get acquainted with the drawings and diagrams of the future structure.Then the master makes a choice of a place for future construction, clears away excess debris and stones, makes markings. After 50 cm of the upper soil layer is removed, a sand cushion is laid, on top of it is geotextiles. Next, a low formwork is done, reinforcement is made and the entire cavity obtained is filled with concrete.After pouring the slab, wait at least 2 weeks, it is also recommended to periodically moisten the foundation, so the cement will gain great strength and strength, which will greatly affect the characteristics of the future garage. And so, time passed and the stove froze well, the author gradually begins to build, first waterproofing spreads over the entire plane of this surface.Further, from the beam, the master begins to assemble the frame, primarily the ends.Makes horizontal connection, as well as jibs.Then proceeds to create a rafter system of the garage.The roof is covered with professional flooring.The walls of the frame structure are finished with OSB plates, window openings are also immediately made.The walls are insulated with mineral wool.Gates made from the same OSB are hungDouble-glazed windows are inserted into window openings.And in fact, the garage itself is ready, though it’s worth outside revealing something else, like a corrugated board or siding. At first glance, the garage of course looks more like a house, by the way in the garage you can make a good room for relaxation, "but that's another story."

This concludes the article. Thanks for attention!

Come visit often, do not miss the latest in the world of homemade goods!

This article is for informational purposes only!