Looking through homemade and comments on them on the site, periodically come across descriptions of various designs used as an auxiliary "third hand", in particular for fixing boards during soldering.

I propose for consideration my version of the holder, which I use in my work.

In connection with the end of the era of film photography, a convenient photo tripod was out of work. I used it as the basis of the proposed holder design.

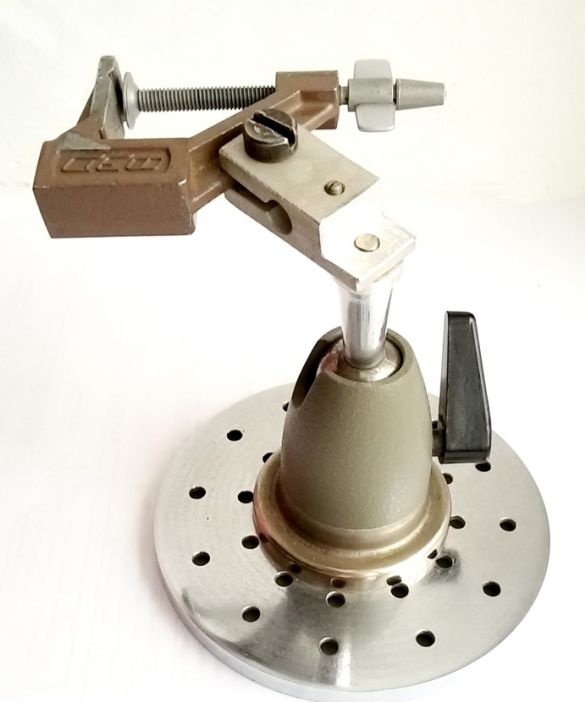

1. Added a few details to it (on the photo 4 from left-down-right):

- a steel decorative element from a broken glass shade of a chandelier;

- top decorative cover from the old lamp, for use as the base of the holder;

- clamp;

- an adapter for connecting the listed parts (made for the holder, made of aluminum alloy).

Parts are described in order to show by way of example that unused parts can be used unexpectedly.

A set of parts for assembling the holder.

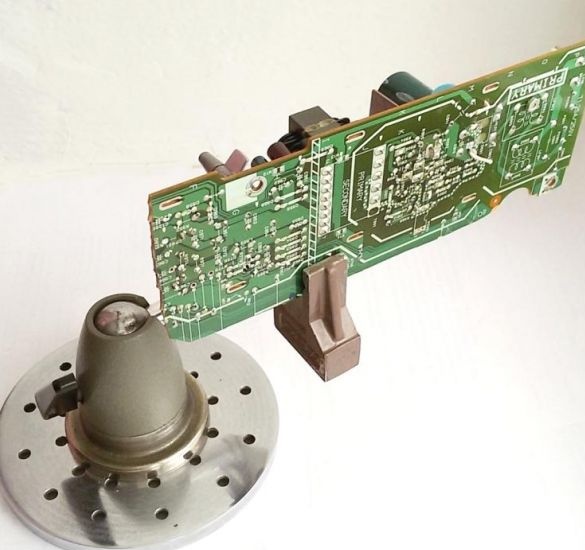

2. We assemble the parts of the holder base by attaching them with the M6 screw, in the center of the parts, to the photo tripod (photo 5).

A large base area, with a low weight of the entire holder, gives good stability of the device when working with it.

Base holder assembly.

3. In the groove of the adapter, screw M8, fasten the clamp to the stiffener (photo 6-9).

We screw the adapter onto the mounting thread of the photo stand. Due to the fact that the thread is special, you must find the appropriate tap for threading in the adapter or look for another way. In my case, it helped that the adapter is made of soft alloy. The steel threaded tip of the photographic stand, due to its hardness, “reshaped” the standard thread of the adapter to fit its thread pitch.

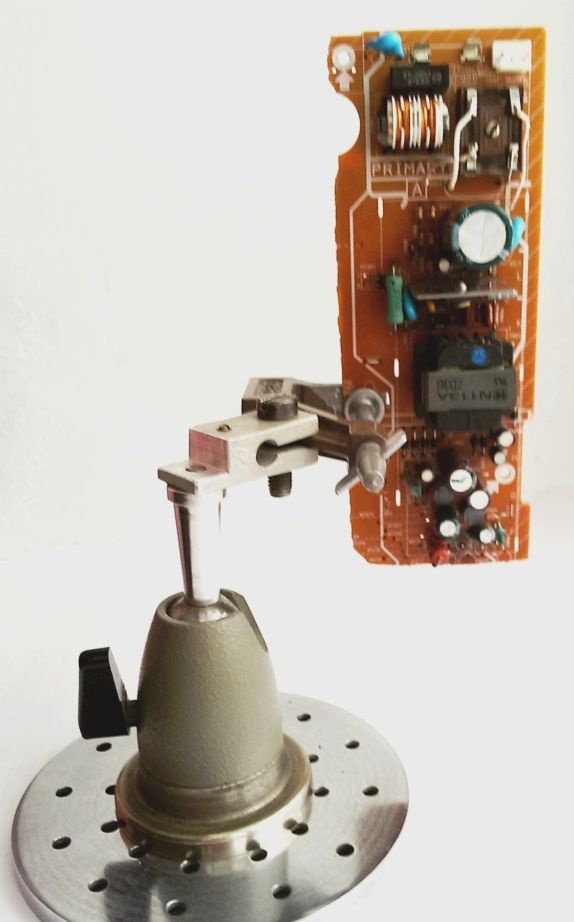

4. The assembled design of the holder allows you to install the clamp in any position

5. Install the board in the holder’s clamp, hold it in a place free from parts, turn the board into a convenient position due to the spherical support, fix the position with the lever of the holder and get to work.

The possibilities of the presented holder are very diverse.

• The holder is simple and convenient to use, lightweight, mobile, not tied to mains or batteries, does not require operating costs.

• Allows you to fix a wide range of different boards, without restrictions on their size and shape.

• Can install and fix the fixed board in any position in space.

• In a few seconds, change the position of the fixed board, without reinstalling it, in any of the 3 coordinates.

• It is possible to use the holder as a "third hand" when mounting and soldering the elements on the board (horizontal position with a rotation of 360 degrees).

• It is possible to install the board in a vertical position (with a rotation of 360 degrees) during assembly and disassembly of parts, when in one hand tweezers with a part on one side of the board and in the other a soldering iron on the other side.

• In addition to installing boards, the holder is also used to install a folding magnifier in it when performing minor tasks, repairing watches.

• Due to the transverse groove of the triangular profile made in the clamp support (photo 4,7,8,9), it is possible to securely fix the hour vise in the holder when working with small objects (hooks, mormyshki), fix the bulb holder for lighting in a shaded place and etc.

• The need for a variety of holder applications is common.