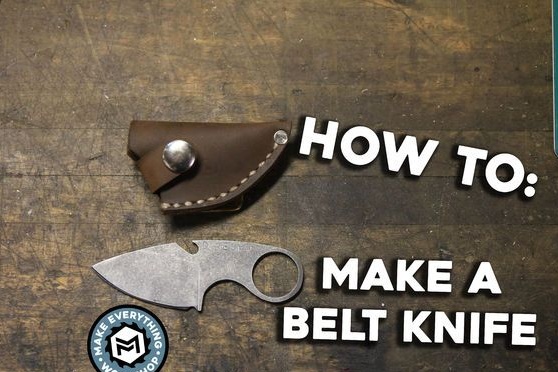

From this instruction you will learn how to make a high-quality knife for daily carrying on your belt (unless of course religion and law allow you

The knife is made professionally, good steel is used here, which is subsequently hardened. So the knife turns out strong and holds sharpening for a long time.

Materials and tools for homemade:

- billet from steel CPM 154;

- paper, scissors, felt-tip pen for making a template;

- drilling machine;

- belt grinding machine;

- band-saw;

- a furnace for hardening steel (automated);

- dremel;

- leather for the manufacture of a cover;

- etching liquid, hammer and more.

The process of making a knife:

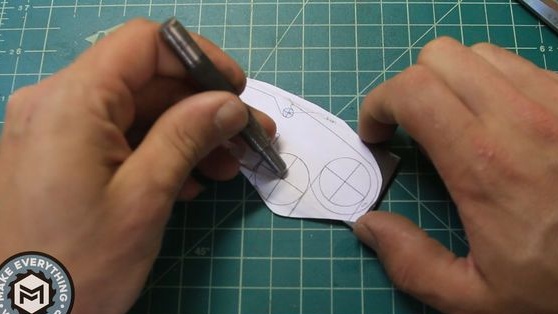

Step one. We make and transfer the template

Everything is done according to a well-established scheme. First, draw or print a template on paper, and then cut it with scissors. Next, the template is glued to the workpiece and you can form the main profile, as well as drill holes.

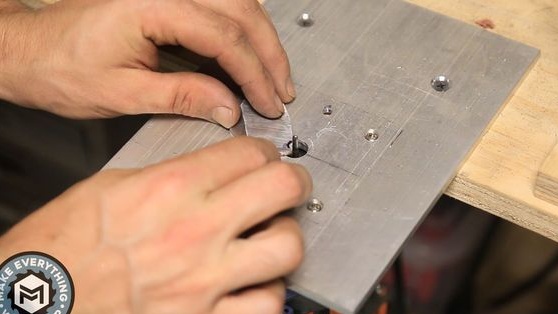

Step Two Drill holes

As a rule, such small knives are equipped with holes for convenient fixing in the hand. Still such openings can be used for various domestic purposes, for example, to open bottles and more.

To cut such a rather large hole, the author used a ring cutter. It is important to remember that when drilling, oil is used, which can easily dissolve the glue and your template will come off the workpiece.

Step Three Cut the initial profile

Now you can form the primary profile of the knife. Then a band saw comes to the rescue. All irregularities are then ground using a belt sander.

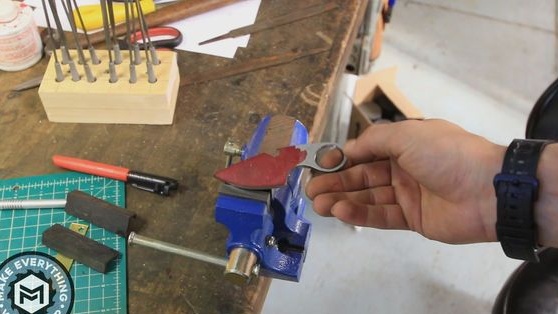

Step Four Bottle opener

If you want to make a bottle opener on your knife, you will need to form a tooth on the workpiece. Here the grinder will come to the rescue, as well as files.Experimentally, it is necessary to ensure that the tooth picks up the lid well and the knife opens the bottle without problems.

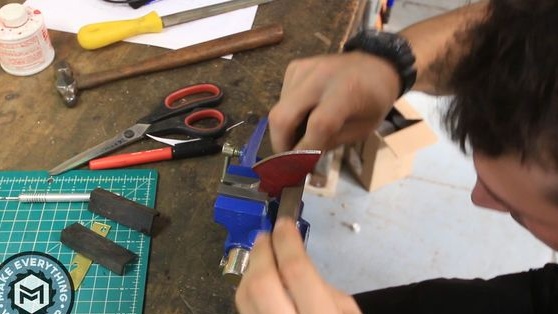

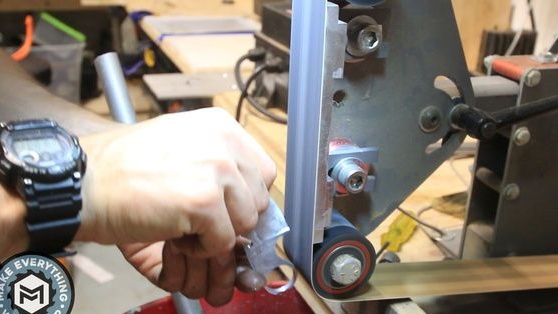

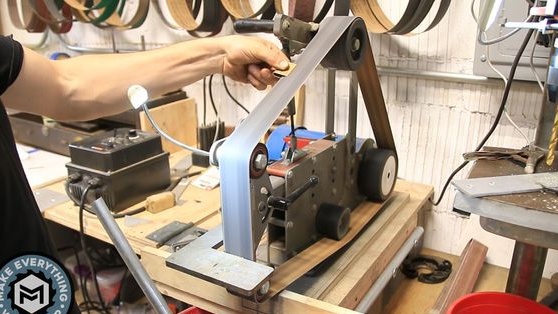

Step Five We make the marking and form the bevels

First of all, the author marks the bevels on the knife, and then a belt sander with belts of different grain sizes comes to the rescue. The author does not use a grinder, sharpened and other tools for these purposes, all work is carried out only on a tape machine. To get symmetrical and high-quality bevels, you will need some experience and patience.

At the end of the blade, the author forms a small rounded cut, which when cutting allows the knife to stop. Some people like it, some don't, everyone here decides for himself whether to do this thing or not.

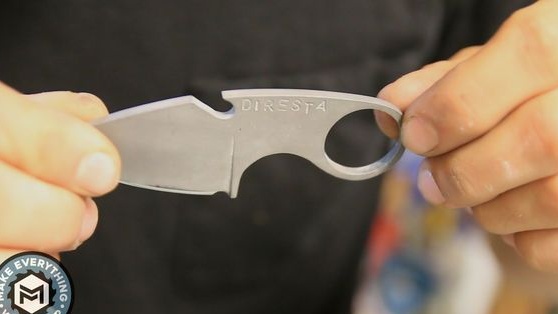

Step Six Stamping

If you want to give someone your knife or just make it unique, you can put a picture on it. The author does this by stamping.

Seventh step. The final formation of the profile

For the most delicate work with the knife profile, the author uses a dremel.

Step Eight. We temper steel

According to the author, when hardening CPM 154 there are some nuances and it will be harder to harden than other common types of steel. For hardening, steel should be placed in a sealed bag made of stainless steel.

The temperature regime here also needs a special one, so if you do not have an automatic furnace for hardening such steel, then it is better to give it to specialists. First, the steel quickly heats up in a furnace to a temperature of 788aboutC (1450 F) and aged 10 minutes. Then the temperature rises to 1052aboutFrom (1925 F) onwards, “fries” for half an hour.

And then even more interesting, for hardening this steel, water or oil is not needed, it is hardened by placing it between two aluminum plates, it needs to be removed from the furnace at a temperature of 1925F. The plates will need to be pressed firmly against the knife, the author does this by his weight.

After hardening, the steel must be let go so that it is not brittle, this is done at a temperature of 425aboutC for two hours. The procedure is repeated two times.

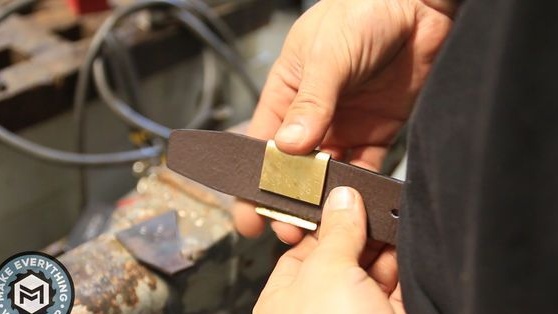

Step Nine. Making a knife case

To make a cover you will need leather. First, the template can be cut out of paper, and then make the same of leather from it.

In order not to lose the knife, the author makes a special lock from brass.

The cover is finally glued, stitched, and rivets are installed.

At the end, the cover is equipped with a holding strap.

Step 10. Grinding

After hardening, the knife is sent to grinding for the last time.

Step 11. Patina

First, the author immerses the knife in acid for etching for half an hour, and then washes it with soap. After that, the blade can be ground a little to make it lighter and get a unique pattern. The author uses some kind of ingenious “cast iron on springs” for grinding, which, using vibrations and pieces of abrasive, forms a unique pattern on the blade.

Step 12. Final sharpening and oil cover protection

At the end, the knife must be brought to a razor condition. This is done on a belt sander by gradually reducing grain size. At the very end, the blade is polished with a belt with special polishing compounds.

A leather case will need to be soaked with oil to protect against moisture, the author used neatsfoot.

That's all, the knife is ready. If it is made correctly, it will be very strong and so sharp that they can cut paper and shave hair.