I purchased electro Dremel on AliExpres. And also nozzles to it.

But disk files refuse to cut even thin tin. Everything else (like plastic and wood) is sawed without problems.

And I decided to use a clamp collet (since it has already been purchased) and make a small cutting disc for myself.

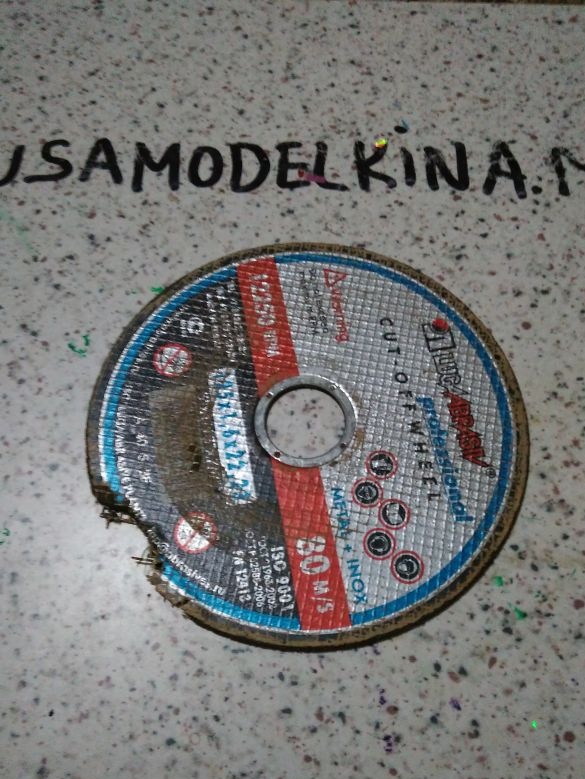

I had a broken disk from a grinder lying at work. It’s scary to work, it’s a pity to throw it out. This is useful.

I picked up a plastic cover in diameter, circled it with a marker around a circle.

Trimmed with scissors. Do not try to trim straight along the line, the scissors will wedge. Leave a few millimeters, then gently finish already.

Now you need to determine the center of the disk, I used a caliper.

Try to measure the center as accurately as possible.

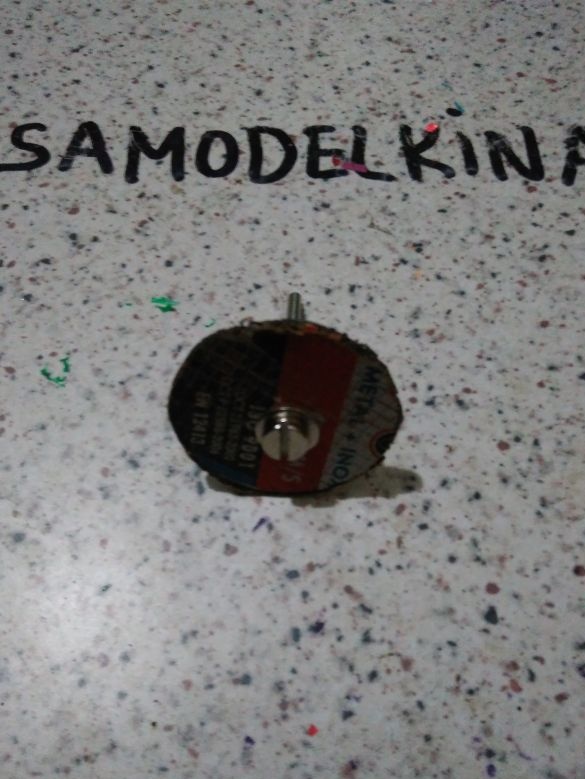

Having measured the diameter of the tightening screw, we drill a hole in the center. And assemble.

At the first test of a disk start, we reduce the speed on Dremel, this is for safety. At low speeds, we begin to slowly file. When the disk is leveled, you can add speed.