In this article, we will consider how to make a boat with a jet engine.

Tools and materials:

-Rule;

-File;

-Scissors for metal;

-Marker;

-Paper;

-Burner;

-Flux;

-Silver solder;

-Welding machine;

-Vise;

-Anvil;

-Hammer;

-Copper tube;

-Copper plate;

-A metal sheet;

Step One: How It Works

The principle of the engine is simple. Two copper tubes are soldered to a closed container. The tubes are brought out under the bottom of the boat. Using a syringe, water is charged into the container through one of the tubes. A fire is made under the tank (dry alcohol, burner). Water is heated and pushed out of the tubes. Then the pressure drops and water is again sucked into the boiler through the pipes. And so until it burns the fuel.

Step Two: Engine

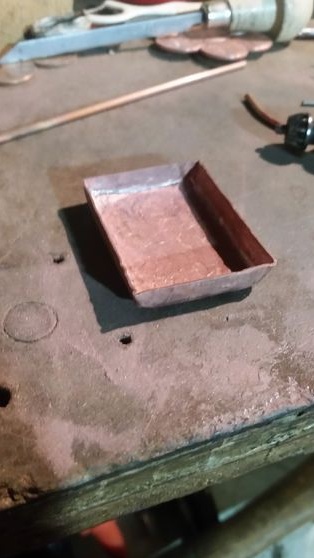

A container is made of a copper plate.

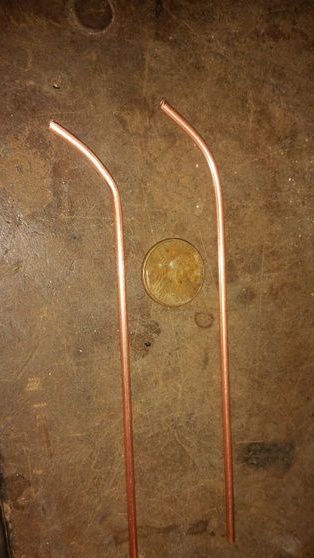

Slices two copper tubes. It bends them as in the photo.

In the bottom of the tank drills two holes. Inserts tubes in them and solders.

Cuts and solders the lid to the container. Now you can check the tightness of the engine. To do this, lower the container into water, plug the end of one tube and blow into the second tube.

Step Three: Burner

The master made the burner from a copper tube. Flattened the edge. Soldered to a copper plate. Poured alcohol inside. Put in the wick.

Step Four: Boat

The hull itself is made of thin sheet metal. Of paper makes a template of the sides. It transfers to metal. Cuts the sides. Welds them.

Cut and weld the bottom.

Two holes are drilled at the bottom of the boat. Sets the capacity. Solder the tube. A plate with a burner is soldered under the container.

Closes the bow.

Makes middle and upper deck. Welds them together.

A copper tube is soldered to the middle deck. Secures the add-in to the body. In order to have access to the boiler and burner, deck superstructures must be removable. The ship is ready. Unfortunately, the author did not post a video test of his ship.

A little from myself. For such a ship, you can use any suitable hull. The boiler can be made from a can.If the upper lid of the boiler is made of thin tin and slightly pressed inward, then when heating the diaphragm (lid) will bend, and when it cools down, it will be replaced. And then the diaphragm will produce a sound similar to the sound of the engine.