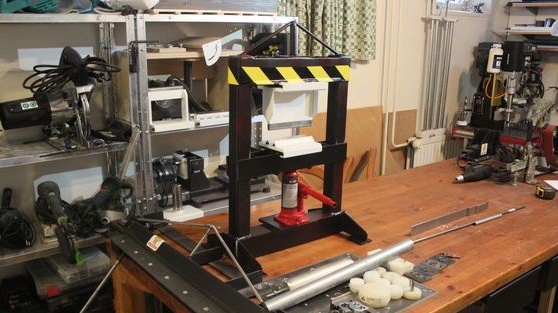

The press made by the author is designed for 6 tons. The hydraulic jack itself is located at the bottom, the workpiece at the top. Also, the master made several devices for the press.

Tools and materials:

-A metal sheet;

-Metal strip;

Cutting machine;

-Welding machine;

- Clamps;

-Hammer;

-Pipe profile;

-Roulette;

-Drilling machine;

-USHM;

-Hydraulic jack;

-Metal rods of different diameters;

- The spray paint;

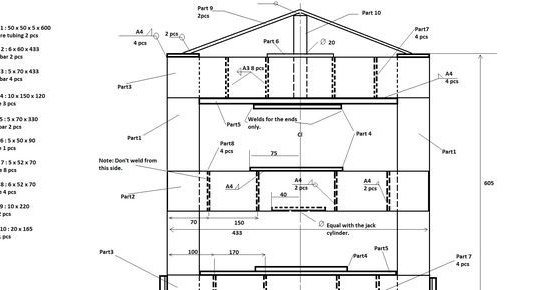

Step One: Project

The first step is the master makes a drawing of the press. Makes the calculation of the required amount of material.

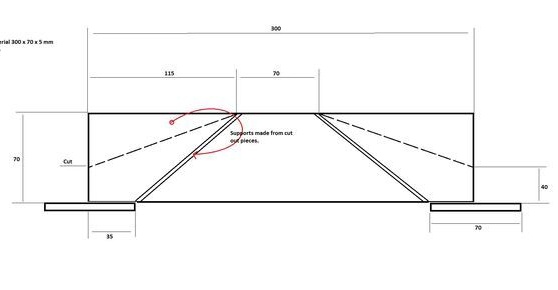

Step Two: Supports

Slices strips and stiffeners.

Welds to a strip of stiffeners. Welds on top of the ribs another strip. Similarly makes two more supports.

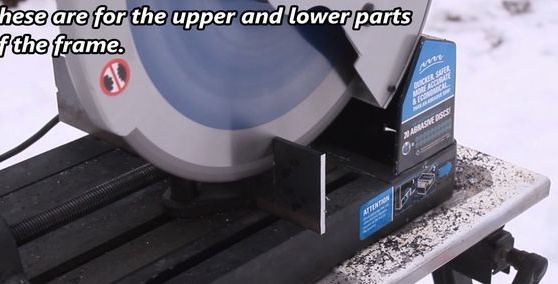

Step Three: Frame

Welds to the lower and upper support of a rack from a profile pipe. Welds legs. Welds a plate of 10 mm metal.

Fourth step: reinforcing the upper support

Boils the seams. Strengthens the upper support with metal rods.

Step Five: Medium

A hole is drilled in the plate along the diameter of the piston of the jack. Welds a plate between stiffeners. Welds a 10 mm plate on top. Now the piston of the jack will be inserted into the bottom plate and abut against the top.

Step Five: Painting

Coats the product with paint.

The press itself is ready. The manufacturing process can be seen in the video.

Another master made various fixtures for the press. There is no manufacturing process, but everything is clear there.

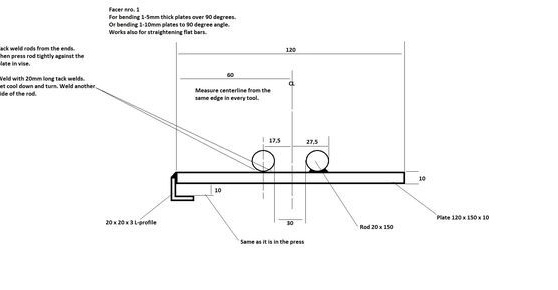

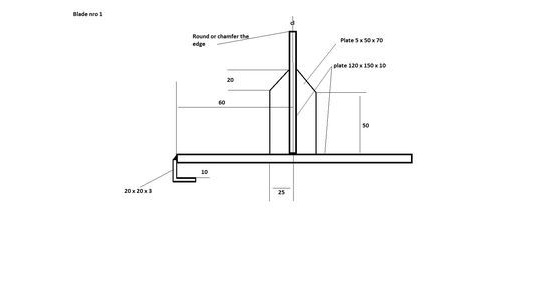

Drawing fixtures.

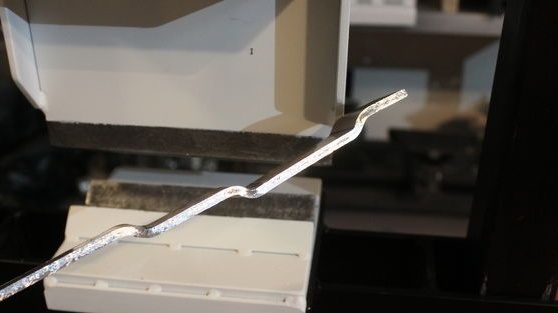

Use photo.

Video work with devices.