Good day to all. In this article, we will get acquainted with the technology of one master for making excellent nippers from old and unnecessary pliers. The advantage of such a tool is that it is able to hold sharpening for a very long time, even when working with solid materials. And so we begin the acquaintance.

The author needed old pliers and a pair of interchangeable plates for a lathe.

First of all, the author will mark up.

Then, holding the pliers in a vice.

It cuts off and drains everything unnecessary.

Since the steel is hard hardened, and the author needs to trim all the bumps with a file. Using a gas burner and dry fuel, he heated the jaws of the pliers and allowed them to cool. After that, he was able to easily process the sponges with a file.

After the author, having attached the plates, he marked with a marker the places of future holes for fastening.

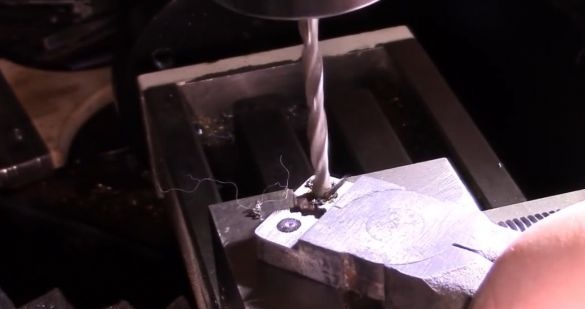

Then he made punching and drilling.

The author used a drill at 4.2 mm with a shortened jumper. And the drilling produces at low speeds so as not to overheat the drill.

Then he cuts the thread under the mounting bolts.

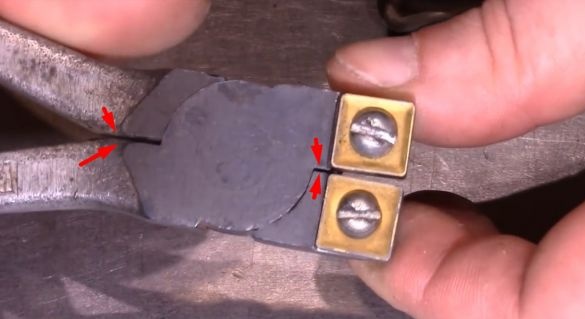

The bolts turned out to be slightly smaller in diameter than the hole on the plates and a small backlash was obtained. By reading the article below we learn: How it can affect the quality robots nippers and how to fix it.

After installing the plates in their places, everything seemed to be smooth, but after the author checked the wire cutters on a piece of tin, he found just such a problem. Not a large gap was formed between the plates, and the nippers will not work with it.

And the author decided to cut the anchor points. Also, according to the author, this problem can be avoided by punching a little closer to each other.

The author recommends taking carbide inserts with good resistance to shock loads. It is good to process such plates with the help of diamond wheels, but if there are none, an emery stone is also suitable.

For ease of processing, the author recommends using smaller bolts and a countersunk head.

One side is completely sharpened.

The author sharpened the second side in a similar way. Too sharpened sharpening plates, the author does not recommend.But if you still decide to make a very sharp sharpening of the plates, then it should be noted that with such sharpening, the sharp edges of the plates should be at a distance of one, two tenths of a mm from each other. This will give a guarantee against chips.

A little check.

The final sharpening and refinement, the author will do using diamond files.

Now a test on a hot spring wire. On ordinary shop pliers, such wire can leave a significant dent, but it does not harm the pliers that the author made.

And in the end, the author will give the made instrument a more aesthetic appearance by polishing it. And making a spring from a hacksaw blade.

The author wraps the handles of the instrument with nylon thread, and with the help of it he strengthens the finished spring.

The author will fix the thread with acrylic-polyurethane varnish for parquet, after saturating it well. This varnish does not smell when dried, but it has excellent hardness.

That's what the author ended up with.

Thank you all and see you soon.

Roller with homemade: