I bring to your attention the most powerful flashlight that works on a 100 Watt LED. With such a spotlight you will not be afraid of any darkness. With it, you can even fight off vampires (hypothetically). In combination with such a bright LED, a lens is also used, which makes it possible to focus the light well.

It’s good to take such a searchlight with you when you go fishing, hunting and so on. But do not forget that the spotlight is not designed for a long period of work and it will need to be charged.

The power source for the flashlight is 18 18650 batteries, they are connected so that they give out 6A at a voltage of 22.2V. The LED is mounted on a powerful radiator with a fan, which does not allow it to warm up above 37-40 degrees. A driver is used to power the diode, which allows you to save power and save the LED.

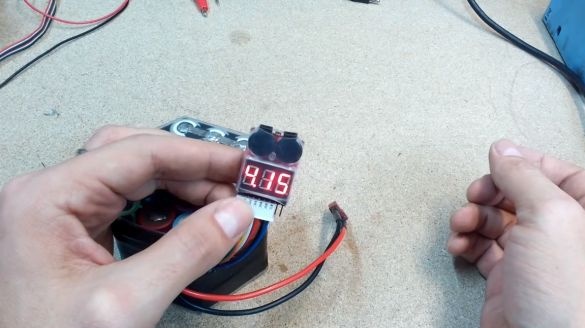

As for battery protection, a controller is used for charging, which will not allow recharging the battery. Also, lithium batteries do not like deep discharge, in order to solve this problem, the author installed a small digital voltmeter that can give an audio signal when the voltage drops below the threshold. The case is made of PVC pipe, everything looks pretty impressive. So, let's take a closer look at how to assemble such a flashlight.

Materials and tools used by the author:

Material List:

- ;

- PVC pipe of suitable diameter;

- cooler from the computer processor;

- ;

- controller for charging batteries;

- 18 standard 18650 batteries;

- digital voltmeter with a buzzer;

- switch;

- socket for charging;

- plywood;

- thermal grease;

- lattices from the cooling system of computers;

- cogs;

- epoxy;

- heat shrink;

- sheet aluminum (to make a pen) and more.

Tool List:

- drill;

- soldering iron;

- multimeter;

- screwdrivers;

- glue gun;

- pliers;

- drill;

- tap.

Flashlight manufacturing process:

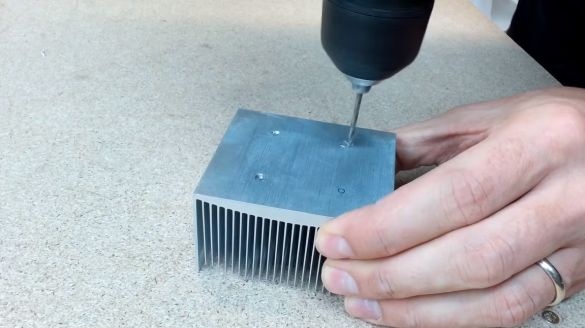

Step one. We prepare the radiator

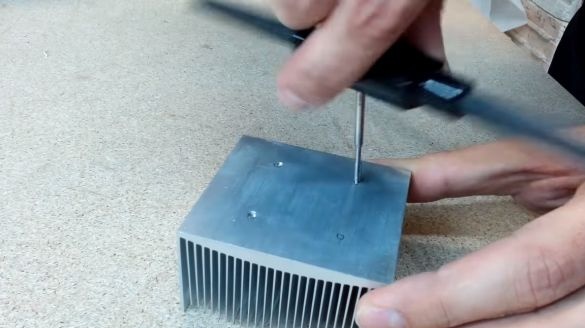

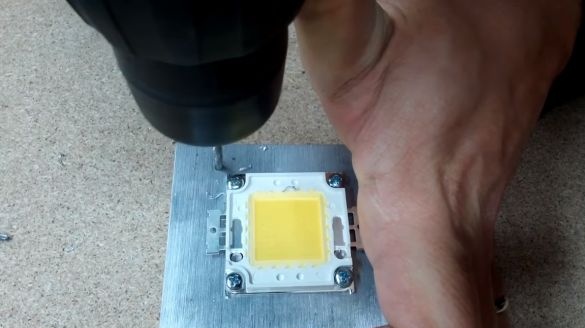

First of all, install an LED on the radiator. To do this, we need a drill, as well as a tap, to thread the screws. Well, then we apply thermal grease to the LED and carefully pull it to the radiator with screws.

After that, you need to install a lens on the LED. For these purposes, the author uses rack bolts, these are bolts with a nut instead of a head.Similarly, drill holes, cut the threads and wrap the racks, you can put them on glue. Well, now we fasten the lens with screws.

Among other things, we need to glue pieces of rubber, pieces of pipe or other similar material on the corners of the radiator so that the radiator does not hang in the pipe, it must go there tightly. The author glues these details using epoxy.

At the end, cut and install a protective grille on the fan so that nothing would prevent it from rotating.

Step Two Radiator installation

To fix the radiator inside the body, which is a pipe, we take a drill and drill holes in which the thread is cut. In these holes we wrap rack screws. Well, then we fix the radiator to the body with screws.

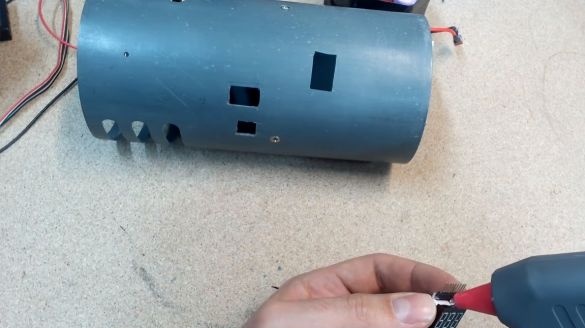

In the place where the radiator is located, make slotted holes for ventilation, the author used a drill for these more fully.

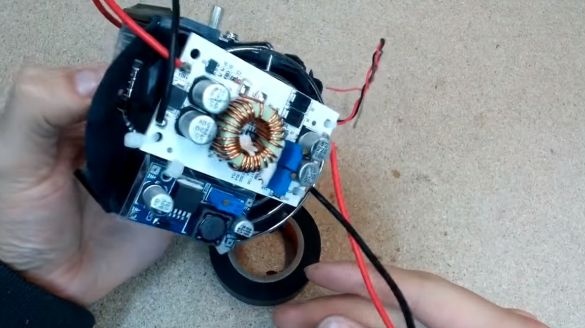

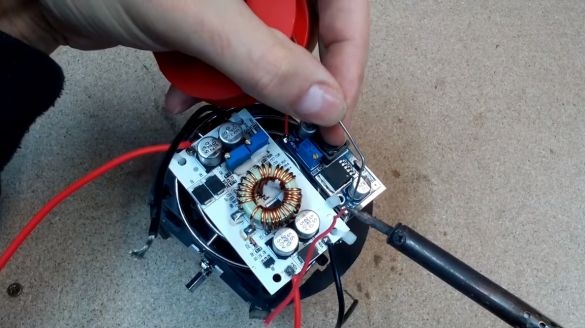

Step Three Electronics Connection

From electronics, we have an LED driver, this, as well as a controller for charging batteries. We connect the LED to the driver and use the adjusting screw to set the desired supply voltage. You can also apply the desired current to the LED so that it burns brighter or dimmer. In addition, the temperature sensor is provided in the circuit; we install it on a radiator. The author fastens the sensor using a strip of electrical tape. Tests have shown that the cooling system is doing its job and the radiator keeps the temperature at 37 degrees.

Step Four Charge switch and connector

We select convenient places for the location of parts on the case and use holes to cut holes. Reinstall the switch and charging socket. If the parts cannot be fixed, you can use epoxy or hot glue.

Step Five We fix the battery pack

You will need to glue the plywood disc to the battery pack. There is enough hot glue, but it is better to use epoxy. Well, then we place the block inside the case and fix it to the plywood disk with screws.

Step Six We connect and install a voltmeter

Lithium batteries are afraid of deep discharge, while they fail. To prevent this, the author installs a small digital voltmeter, which will notify with a sound signal if the charge voltage drops below acceptable. To install this part, we cut out a square window in the case and set the voltmeter on hot glue. If the speakers will interfere with the installation, they can be moved to the opposite side.

Seventh step. Close the case

First of all, you need to fix the batteries so that they do not fall out of the pipe. To do this, we take a plate of aluminum and bend it in the form of the letter "P", at the ends we drill holes and cut the thread. Now install this support inside, holding the batteries in place, screw it on.

The author also decided to install a protective grill, which makes the flashlight more beautiful. As a grill we use spare parts from a computer cooling system.

Step Eight. Handle and legs

For a flashlight, you definitely need to make a pen, the one as it is quite large and weighty. For these purposes, we take a strip of aluminum and form the desired profile. And to make the pen more beautiful and more pleasant to the touch, put on a heat shrink on it. We fasten the handle to the body with screws and nuts.

It is also extremely important to make legs for the flashlight. To do this, cut two pieces from the PVC pipe, bend and glue the legs using epoxy. You can also screw several screws into the case as legs. After that, you can conveniently put the flashlight, and it will not roll off.

Step Nine. Challenges!

The lantern is ready, you can test it! The author in the video has a demonstration of his work. It shines very brightly and quite far.Such a lantern can easily give a distress signal, which will be seen at fairly large distances.

The entire floodlight amounted to 1.750 kg, most of all while weighing batteries and a radiator. The length of the lamp is about 22 cm, and the diameter is about 11 cm.

That's all, I hope you enjoyed the project! Good luck and inspiration in making your own flashlight!