Good all the time of the day, I want to share the idea of acoustic styling that has spontaneously arisen.

The long-lying speakers, of average power, pushed me to refine them and improve their acoustic qualities ...

After thinking and searching for “gimmicks”, I picked up the material and tool I needed, practically without resorting to additional costs for purchases, since almost everything I needed was found at my place.

The main material for the manufacture will be dense foam. Polyfoam I think is an excellent material for acoustic sound, because it eliminates any jitter that distorts the sound.

So let's get started

We will need the following:

- directly speaker

- dense foam (I have a thickness of 20 mm)

- fabric for tight

- silicone with a gun

- knife (clerical)

- marker

- measuring tool (in this case a square with a measuring scale)

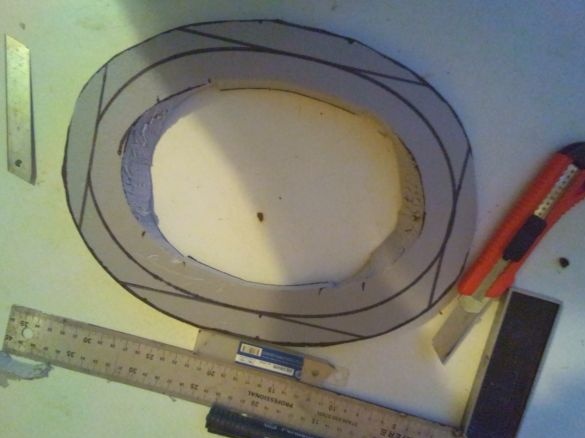

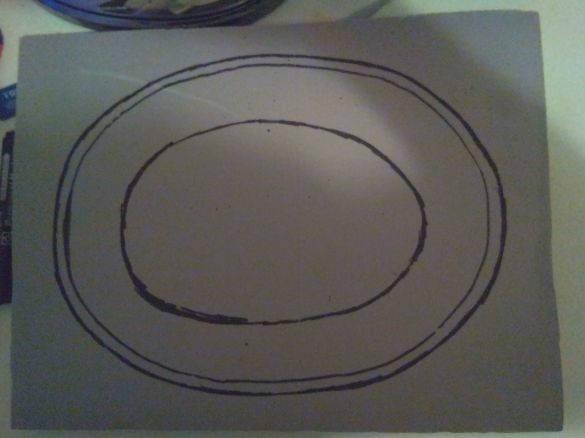

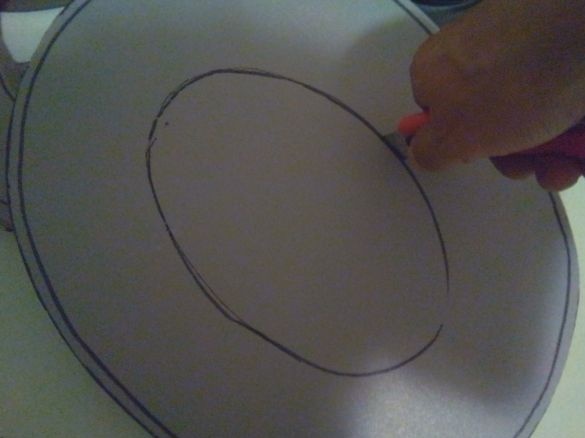

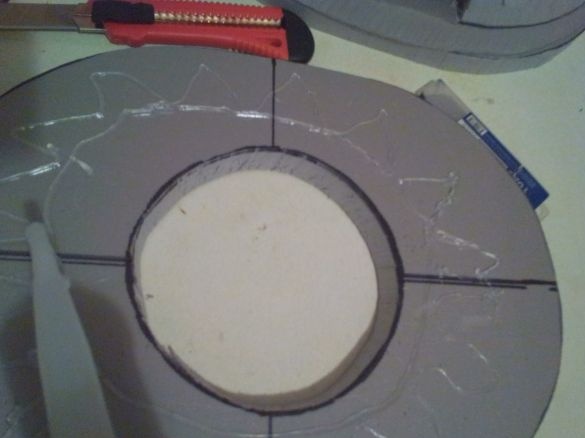

We take the speaker and polystyrene, mark the seat and step back from its edges 20 mm, then from this marking another 20 mm, make marking strips. We cut the oval at the extreme mark, then the seat (we try to cut out the speaker according to the relief, for a more snug fit).

We cut the edge at an angle from the central marking to the edge

We mark the second part along the upper part, circle around the edge with a marker, add about 5 mm and make another + - 2 mm strip (accuracy is not very important here, as it will be adjusted, the upper and lower parts should be with the exact size), this will be edge of the 2nd part and cut off the excess.

The inner part is cut out the same as the seat, only without relief.

In this sequence, we mark and cut out the following parts, there are five in total (along the 2nd, 3rd, etc.

We mark the lower (5th part) with the exact size and center of the oval as well as the 1st.

We mark the center only under the magnet, add a little, for its free placement, cut out at the extreme strip.

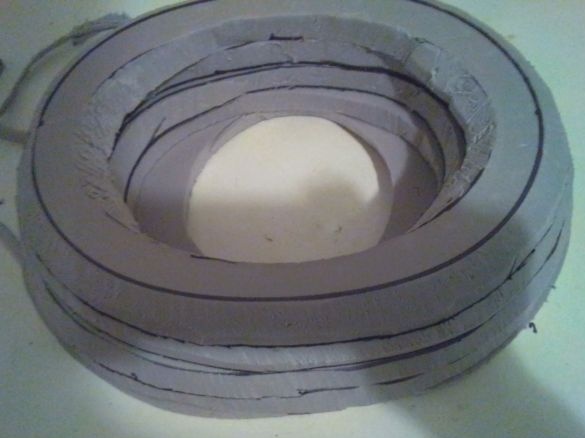

We try on the resulting parts, sequentially adding them (from larger to smaller

In the middle part, it is necessary to remove part of the foam (pre-marked), as follows

When assembling, it should work like this

If you get about the desired shape (do not get scared of the plain appearance), proceed to gluing the elements. We will glue it with silicone, since the glue can corrode foam, of course gluing with water-based glue is possible, but on silicone the design will be more elastic ("live"), which contributes to the best sound ...

Correct irregularities, cut off all the bulges in a smoothly passing line, you can use sandpaper

And the final point, tight.

Making a semicircular pattern

We also glue on silicone. Apply silicone to the surface tightly wrap with a cloth, cut off excess and roll with a roller

Done

When using, it is necessary to screw it onto a hard flat surface together with the speaker, first apply silicone to the seat.