Good day to all. Today I will please music lovers and ordinary people who love a good, loud sound.

This time I will show you how to make speakers from inexpensive materials. This idea is not mine, the author of this idea is a student from SRM University "patrick panikulam" can visit his page on instructables website. I just translated his article into Russian, for those who do not understand English. I will try to convey to you the whole process of work and I hope that you will not have any problems. Well, let's begin, we will need.

Materials:

1. YAMAHA TA2024 Amplifier x1 ()

2. 3-inch, 15 Watt speakers x2 ()

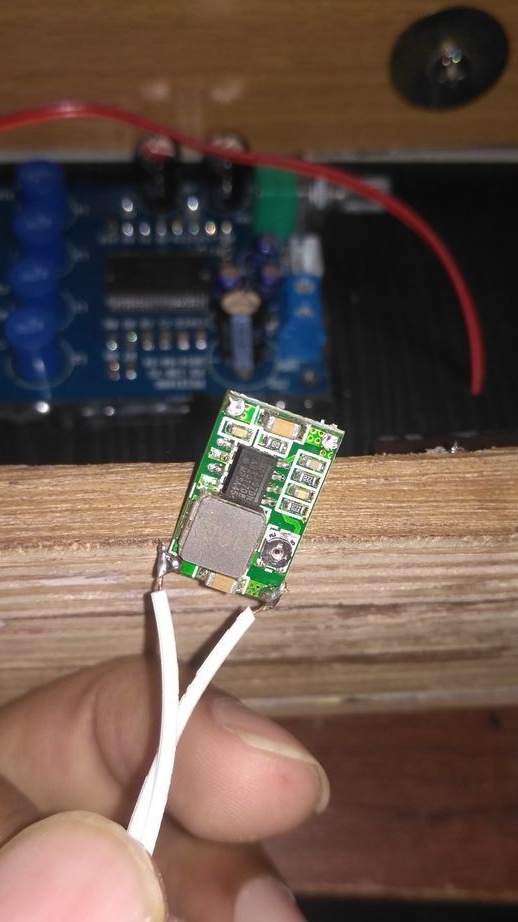

3. DC-DC buck converter ()

4. Passive radiators (60X90 mm) x2 ()

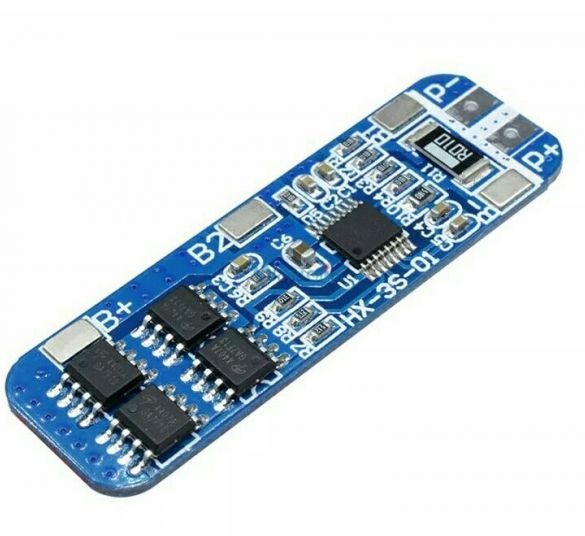

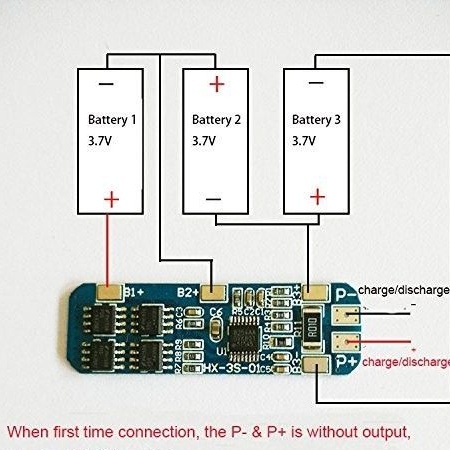

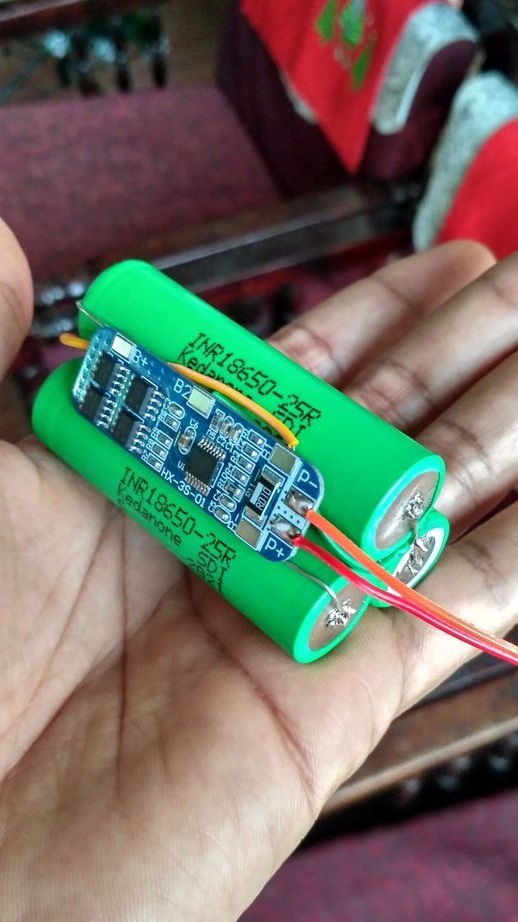

5. Charging board 12V 18650 10A BMS x1 ()

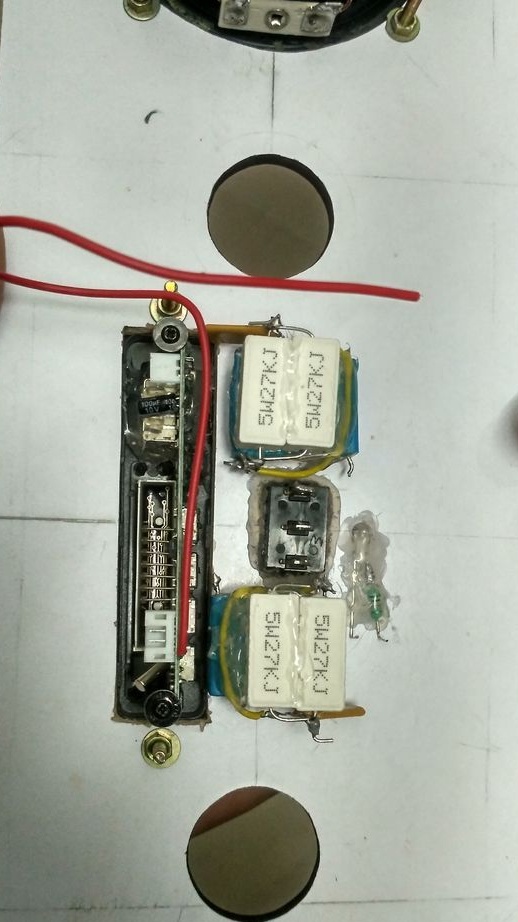

6. Frequency crossover x2 ()

7. Charger 12.6 V (2.1 mm plug) x1 ()

8. DC-DC boost converter x1 ()

9. Tweeters x2 ()

10. Bluetooth 12V MP3 WMA Decoder x1 ()

11. Battery 18650 (capacity of your choice) x3 ()

12. Charging connector DC-099 x1 ()

13. Push button switch x1 ()

14. Connecting wires

15. PVA

16.4000uf 16V capacitor

17. Varnish

18. Sealant

19. Sandpaper

20.3 mm LEDs

21. Plywood sheet 18 mm.

22.5 mm plywood

23. M3 and M4 nuts and bolts

Instruments:

1. Screwdriver

2. Soldering iron

3. Saw

4. Sandpaper

5. Rotary tool

6. Glue gun

7. Scissors

8. Pliers

9. A set of drills

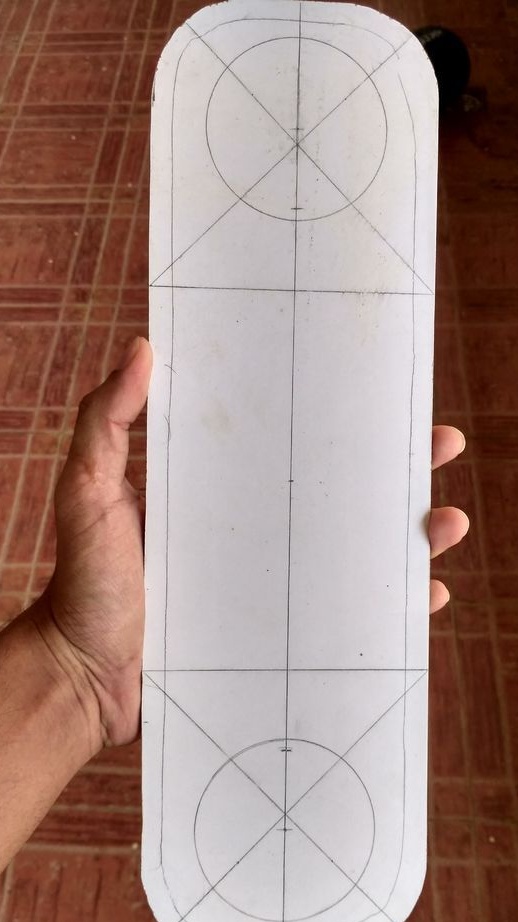

Step 1. Front Panel Design

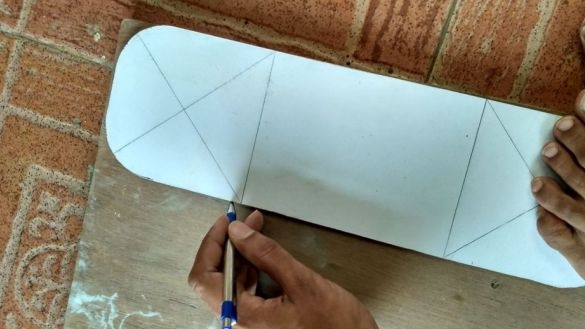

At this stage, the front panel of 5 mm plywood is cut out. On this panel will be mounted speakers, switch, diode, etc. Panel sizes are calculated on 3-inch speakers. The author did not give the dimensions of the panel. The edges of the panel are rounded.

Step 2. Cutting according to the drawing

Now putting the cutting bit on the rotary tool, the holes are cut for 3-inch speakers, for 1-inch tweeters, for a decoder in size and for a switch. Then the speaker mount points are marked (they will be mounted on m4 - 3 mm screws) and 3 mm holes are drilled. All holes are filed.

Step 3. Making the case

[/ center]

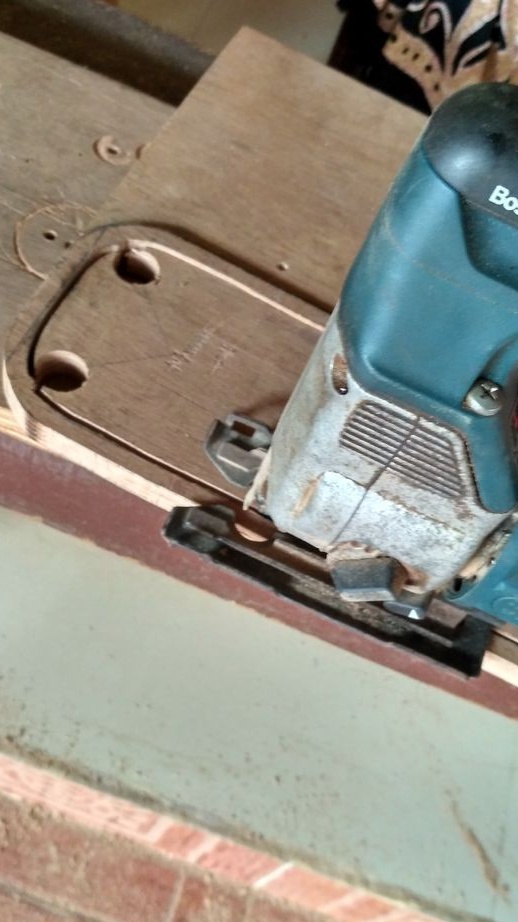

[/ center]The next step is to put a panel on a 15 mm plywood and draw it with a pencil (the panel should fit tightly into the case). On top of the drawing, another one is drawn at 8 mm distances. And with a jigsaw cut three of these rings. Then all the rings are glued together with PVA glue and left under pressure for the night.After drying, the body is sanded with sandpaper, from coarse to very soft, until you are satisfied with the finish. 3 layers of PVA are applied to the inside and all cracks are closed with wood sealant.

Step 4. Making the back panel and handle

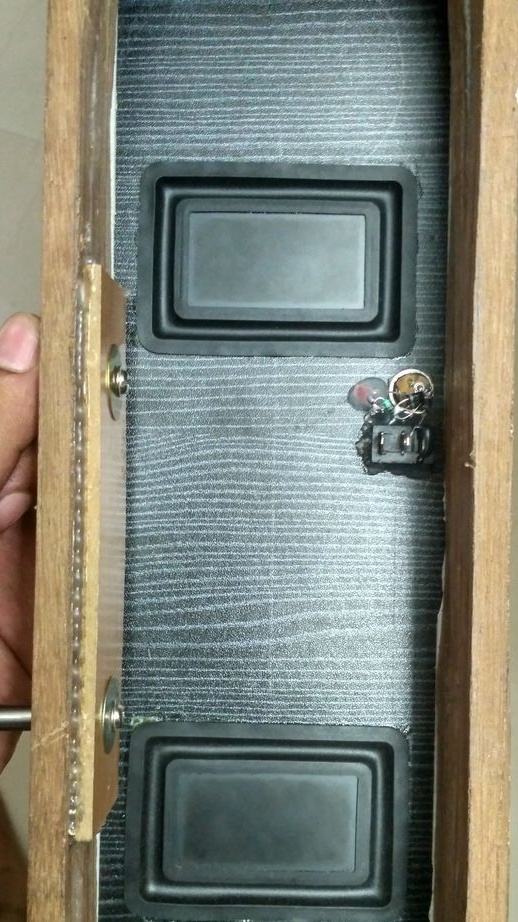

On 5 mm plywood, a contour is marked and cut with a jigsaw. Holes for radiators and power connectors are cut out on the panel. Holes for screws are drilled along the edges. A handle is attached to the housing for convenience.

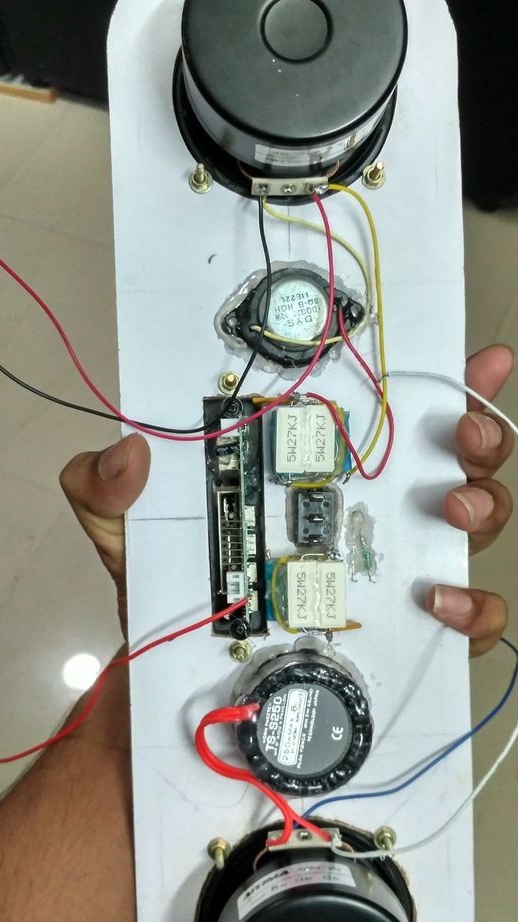

Step 5. Fixing the front panel components

The first step is to attach a power LED with a 10th resistor, hot glue. Then the wires are soldered to the decoder, switch, tweeters and speakers. Speakers connect with tweeters.

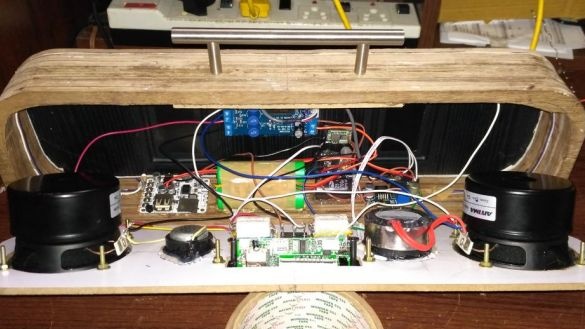

Step 6: connection electronic components

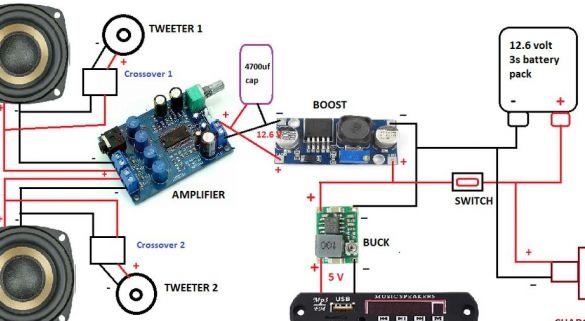

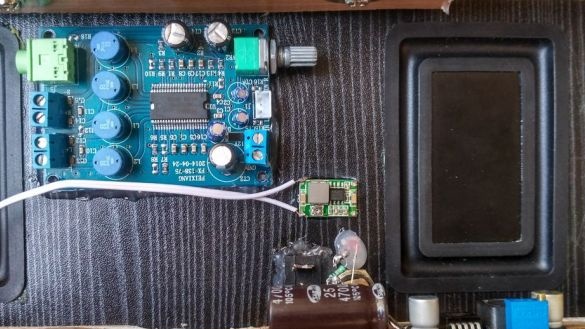

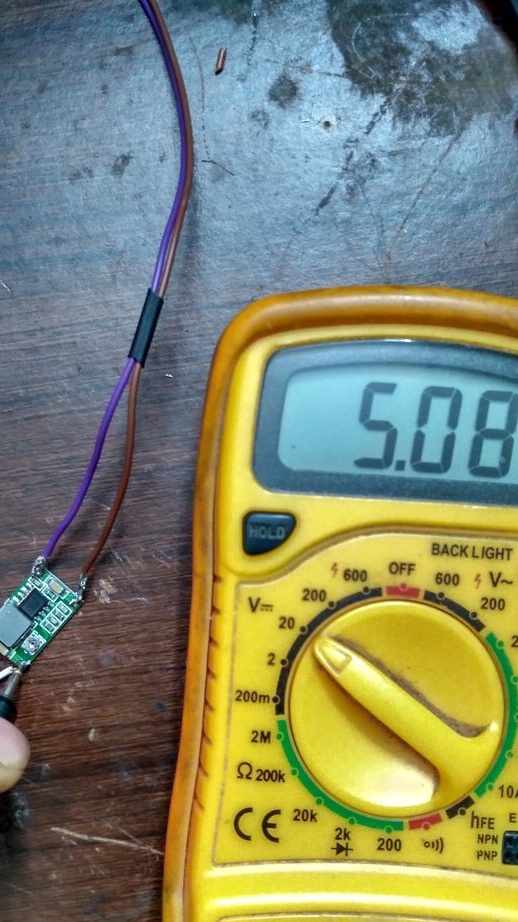

Connecting cells to the BMS in accordance with the electrical diagram. BMS is reset and starts to work only after the charger is connected to the output. Connect a DC-DC boost converter to the battery output (Be careful with polarity). All other components are wired together.

Step 7. Fixing the back panel components

The charging socket is installed in place with glue, just like radiators. The 4700uf capacitor is connected to the output of the boost converter. The remaining components are also placed using glue and connected to each other using wires in accordance with the electrical circuit.

Step 8. Connection of housing elements

When all electronic components are installed and connected, the back and front panels are attached to the body (between the junction of the rear panel and the body you need to glue a thick layer of double-sided tape, this is done for sealing). The front panel is glued with PVA glue.

Step 9. FINAL

Final grinding is done, the front and rear panels are closed with paper and tape. The remaining part is varnished in 3 layers and four rubber legs are attached. That's all the column is ready. I hope the article is interesting and informative. Thanks for watching, like if not difficult.