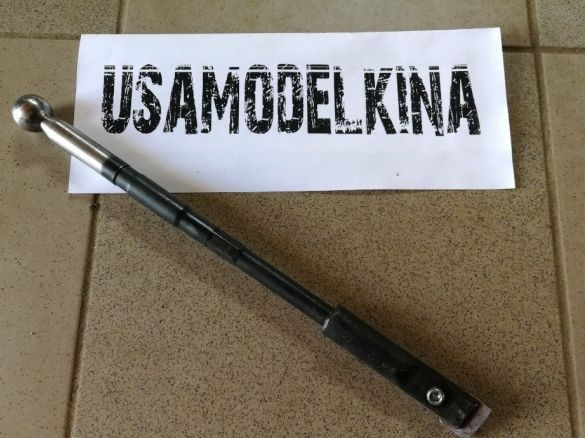

Hello to all lovers homemade. In this article I will tell you how to make a scraper from the tie rod do it yourself. Using this fixtures you can clean metal surfaces from old paint and rust. Also, a scraper can fit two mating surfaces, for example, on a lathe, the guides are usually scrapped. All parts used in homemade products are made from old car parts.

Before reading this article, I suggest watching a video in which the entire assembly process of the scraper is shown in detail, as well as its testing in real conditions.

In order to make a scraper from the steering rod with your own hands, you will need:

* Old steering rod from auto

* Angle grinder, cutting disc

* Personal protective equipment, gloves, earphones, goggles

* Electric drill, drill for metal with a diameter of 5 mm

* M6 tap

* M6 thread bolt

* Bench vise

* File

* Steering tip

* Spray paint can

* Valve clearance adjuster

Step one.

First you need to free the steering rod from the hinge. We install it in a bench vise and, using an angle grinder with an installed cutting wheel, saw off the hinge, being careful not to damage the ball on the rod. When working with the angle grinder, be careful and wear safety glasses, earphones and gloves.

Step Two

To fix the scraper plate, which also needs to be done, it is necessary to cut off the excess part from the steering tip using angle grinders.

Next, we mark the line in the middle at the end of the sawn blank.

Then we clamp it in a vise and begin to make a cut of 4 mm thick, which is equal to the thickness of the washer, for this we install three cutting discs in the angle grinder.

After the cut is ready, try on the puck, it should be tightly installed in it.

If necessary, trim the groove with a file.

In order to be able to clamp the puck into the parts, we saw another groove, but deeper. In the end, it should look like this.

Step Three

Make a mark for drilling holes in the workpiece.

Then we fix the workpiece in a vice. We drill a through hole using an electric drill with a 5 mm metal drill installed in its chuck.

After that, we cut the thread using the M6 tap. In the process of threading, we lubricate the cutting edge of the tool with technical oil, so it will last longer.

Check how the bolt is screwed in by hand.

Step Four

Now for the scraper you need to make a scraper plate. We make it from the valve clearance adjustment washer, first we mark with a marker, and then with the help of an angle grinder we saw off the excess parts.

After manipulating with angle grinders, such a plate was obtained.

The working edge was slightly rounded. At the end, we paint the handle from the tie rod with a spray can with hammer paint.

Step Five

We install the plate in its place, then fix it with a bolt using a hexagon.

It's time to test the tool at work. To do this, take the scraper and begin to scrape the surface of the metal plate, slightly pressing on it.

The result is such a smooth and even plate without any rust.

That's all for me, thank you all for your attention and good luck in the new homemade products.