This article will discuss how the master made the puller do it yourself from old open-end wrenches. According to the author, such an instrument can be used to remove both external and internal bearings. Who cares, read the article further.

And so the author for this homemade such materials were required: a M 10 pin, a pair of nuts for it, four rectangular metal plates with a thickness of 4 mm and a length of 50 mm, two open-end wrenches of the same (the author had 12 by 14) and several more M 8 bolts and nuts for them.

The first thing I did was mark up one of the keys.

Then with the help of angle grinder I cut off all unnecessary.

I processed the cut with a file.

Finished part.

In a similar way, he made the second key.

Then he makes a hole in the middle of the processed keys.

On all four plates, the author makes two holes.

Finished parts.

Then, twisting two nuts on a stud will weld them together.

After, one more nut will be welded to these nuts on the side.

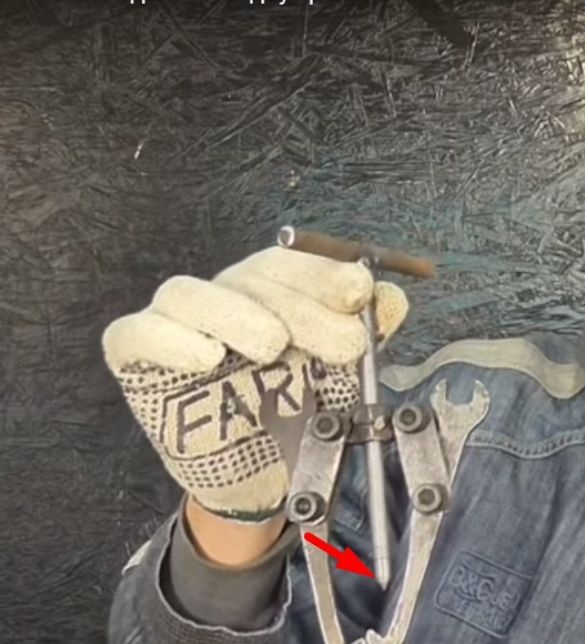

When all the parts were ready, I started assembling the tool.

And in the end, he welded a piece of reinforcement to the stud that would serve as a handle.

Such is the universal puller obtained by the author.

The second edge of the hairpin is a little grind.

Test. Outer bearing.

In order to remove the inner bearing, the author turned the keys over and set the hairpin longer. Threading the stud into the bearing, screwed a nut onto it.

The keys rests in the case.

And twists the hairpin.

Thus, the bearing is removed. The tool coped with its task.

Thank you all and see you soon.

Video: