In this article, the Wizard will tell us how to make and install the railing on the stairs. To make the railing he needed the following

Tools and materials:

-Welding machine;

-CNC machine;

-USHM;

-Drill;

-Miter saw;

-A circular saw;

- Clamps;

-Construction hair dryer;

-Hammer;

-Brush for metal;

-Electrodes;

-Drill;

-Protective mask;

-Rule;

-Different circles on angle grinder;

-Sandpaper;

-Stainless steel profile;

-Stainless steel balls;

- Corner made of stainless steel;

-Board;

Epoxy resin;

- fluorescent powder;

Step One: Project

First, the master made the design of the fence and figured out how much and what kind of material he would need. The master makes the fence of a stainless profile in different sizes. Wooden inserts with a pattern filled with epoxy resin with a fluorescent filler will be attached to the posts.

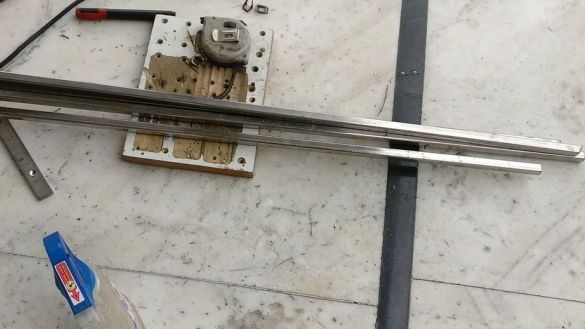

Step Two: Cutting the Profile

Next, the master cuts the profile to fit.

Cleans the edges of the workpieces.

Step Three: Trims for Upper and Lower Column

Cuts boards to size. Grinds.

Using a CNC machine, it applies a pattern to the surface of the boards.

It covers the surface around the pattern with masking tape and fills the pattern with resin mixed with dye. After hardening, it polishes the surface and coates the remainder.

Step Four: Upper and Lower Bars

Then proceeds to welding. Welds the anchor bolt to the column plate. Welds the profile pipe between the plates. Then collects a wooden insert. At the corners sets the corners and welds to the lower and upper supports.

After welding, it cleans and grinds the seams.

Step Five: Installing the Lower and Upper Columns

He makes markings on the stairs under the posts. In marble, a diamond drill, the master drills holes. Fills the hole with mortar and sets the posts.

Step Six: Ball

Polishes the top plate of the posts. A bolt is welded in the center of the plate. Sets the bottom cup. Tightens the ball.

Seventh step: middle columns

It procures material for medium columns.

In the middle part of these columns there will be a rectangle to which a board with a pattern will be attached. Welds the posts.

Makes fastening and welds it to the posts, after having put on the decorative cap.

Step Eight: Installation

The installation of the middle columns is the same as the extreme ones. Marking, drilling, grouting, installation.

Step Nine: Handrails

Cut and weld handrails. After welding, it polishes and polishes the surface.

Step Ten: Protective Fence

Cut and weld the safety guard. For fastening to the upper and lower columns, it makes a plate. A profile is welded to the plate, and then the plate is screwed to the column.

Step eleven: wood inserts

Saw the board to size. Grinds the surface. With the help of a CNC machine, a pattern is cut. It paints the boards. After drying, varnishes the surface.

Now you need to fill the picture with resin with a luminous powder. Since the drawing, the color master does the following: covers the surface around the drawing with masking tape, separates the areas of the drawing with hot-melt adhesive partitions, fills each zone with a resin solution with its own color of fluorescent powder, heats the resin with a hairdryer to remove bubbles.

After drying, the resin polishes the surface and reapplies paint to the area around the drawings.

Step Twelve: Installing Wood Inserts

Glues wood inserts into the inside of the rectangle columns.

Step Thirteen: Polishing the Railings

After the railing is installed, the master polishes their surfaces using angle grinders and polishing paste.

Railing made and installed.

The whole process of manufacturing and installing the railing can be seen in the video.