In this homemade Andrey Vinnichuk will assemble the machine.

This device is intended for the manufacture of special elements by cold forging, without heating. And of them, in turn, will collect a decorative lattice.

In one of the articles a machine will be presented, with the help of which it is also possible to manufacture such a grid.

But in the process of working with it, it is required to heat the workpieces, and this increases the cost and complicates the production.

It also takes more time to make blanks.

In this article, Andrew will do device with the help of a grinder and welding, very simple, without the use of turning and milling operations.

The author will make the main working surfaces from an automobile spring.

Her steel is very strong, and there is no difficulty in getting it.

At the end of the article, let's look at the capabilities of this device in operation.

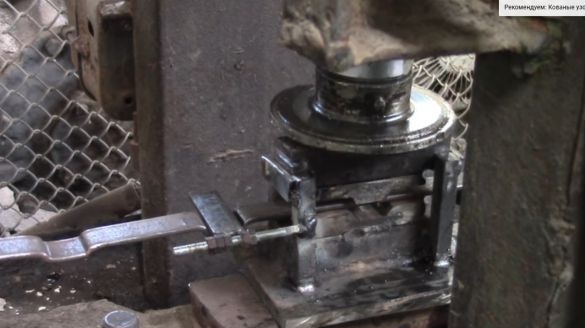

Performing the upper part, the author uses a square bar with a section of 30X30mm.

In the blanks cuts out the grooves grinder.

A prepared piece of spring is welded to it.

The upper part is made in the form of a protrusion.

The lower part is also welded to a piece of square rod with a cross section of 30X30mm.

The bar itself is welded to a 10mm thick plate.

In a segment of the spring made a recess.

Further, it makes guides using a square rod with a section of 12X12 mm.

The author will not invent or invent anything more.

It will turn out a simple and effective machine.

The author made two such strips, fixes them on one and the other side.

It is scalding finally and we will soon check it in practice.

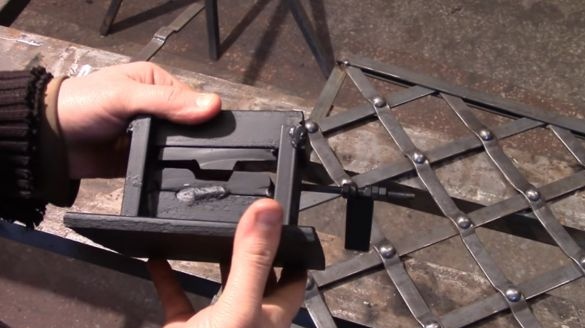

Next, he will make an important device, in the form of a flag.

It is necessary for the convenience of adjusting the distance between the punched grooves.

Also, it will allow you to reduce or increase this distance.

This is a simple but necessary device made, now you need to fix it.

At about this distance.Here is such a simple mechanism that makes it possible to adjust the distance between the waves. To do this, the flag moves along the hairpin to the right or left. Then fixed with nuts.

The author applies a strip of 20x4mm.

Andrei often uses this material in his work.

Actually the bending process.

He almost always makes this lattice from a strip 20x4.

The result is not only a decorative and beautiful product, it can also perform protective functions.

This method is much easier than manufacturing using the method of heating billets.

It is economical and faster.

Here is such a decorative product, the appearance of which compares it favorably with similar gratings, the elements of which were made manually, by hot forging.

This is the speed of manufacture and profitability.

You can clearly see how the metal looks. There are no shortcomings that always arise as a result of heating elements on coal in the furnace. There is no slag and scale. Therefore, it is not necessary to strip and clean the product from them. Really very effective and profitable.

A stanochka can now be painted.

If there is no such hydraulic press that the author used in the work, you can use a conventional hydraulic jack, or a manual press.

Thanks to Andrey Vinnichuk for the work done.

Link to the original video - under the text is the "source" button