Ring flash and lighting are used mainly for macro photography. Such illumination of the object gives almost no shadow. Make ring lighting do it yourself decided Master. Let's see how he made it and what came of it.

Tools and materials:

-3D printer;

-Glue;

-LED Strip Light;

- Aerosol can with paint;

-Screwdriver;

-Compass;

-White plastic;

- Sealant;

-Scissors;

-Knife;

-Soldering iron;

-The wire;

-Nippers;

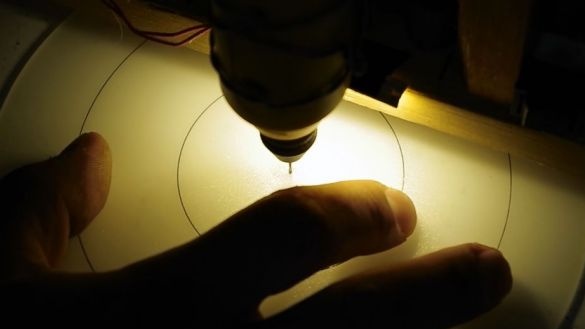

-Drill;

-Connector;

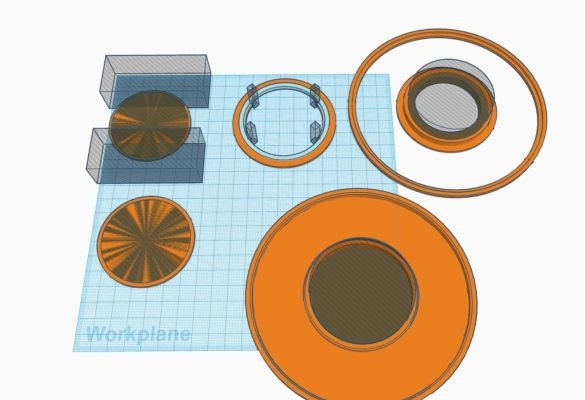

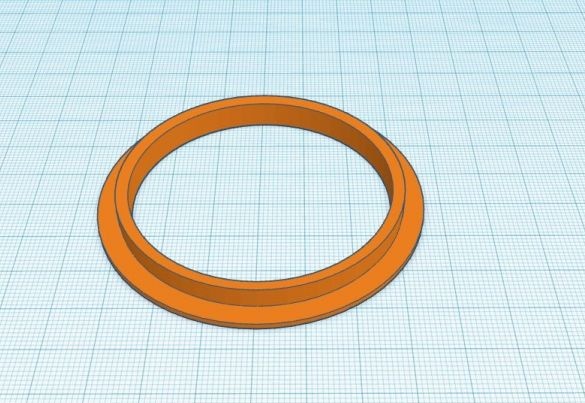

Step One: 3D Printing

On the 3D printer, the wizard prints the necessary details. Details are adapted for the Pentax K50 camera with a whale lens 18-55. The outer diameter of the ring is 140 mm.

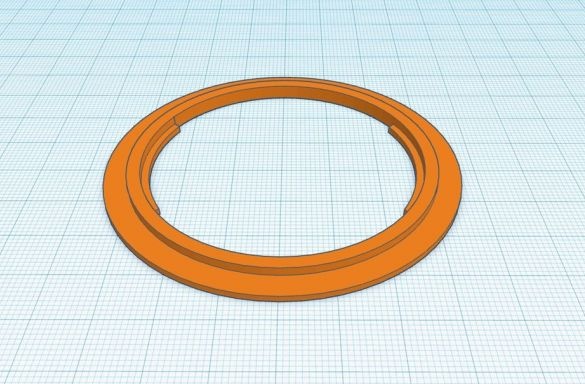

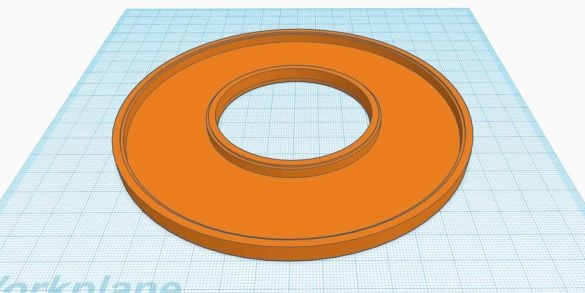

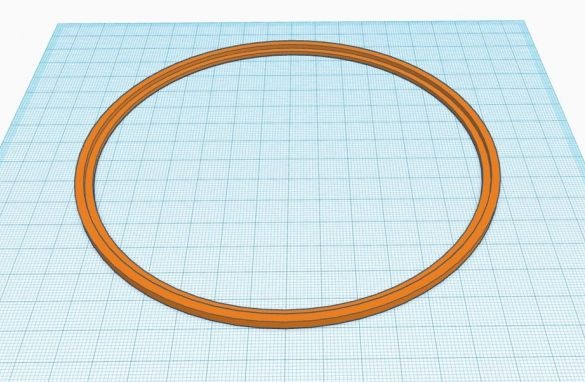

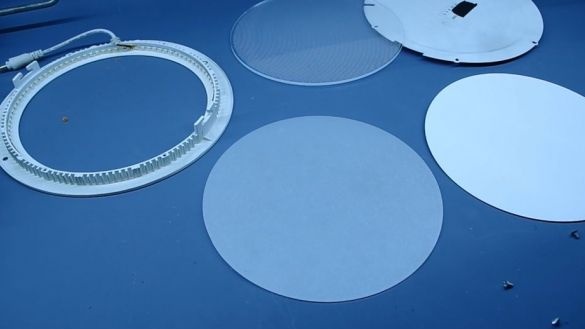

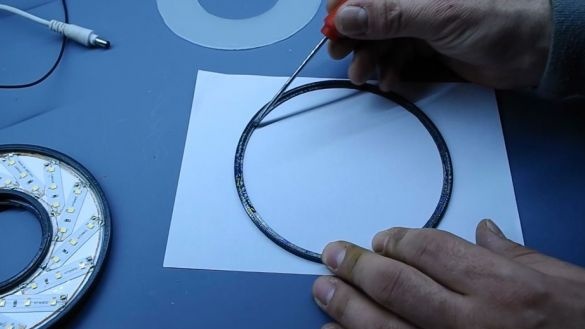

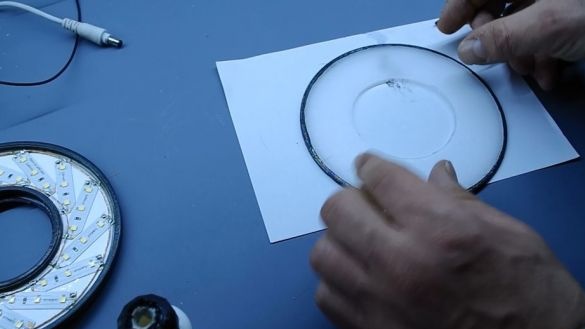

Step two: inner and outer ring

Glues the inner ring, as in the photo.

Checks the diameter.

Step Three: Painting

Colors the item black.

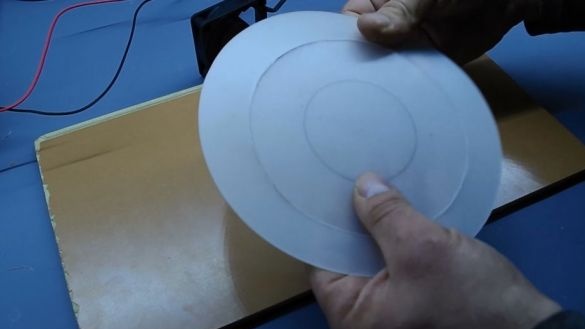

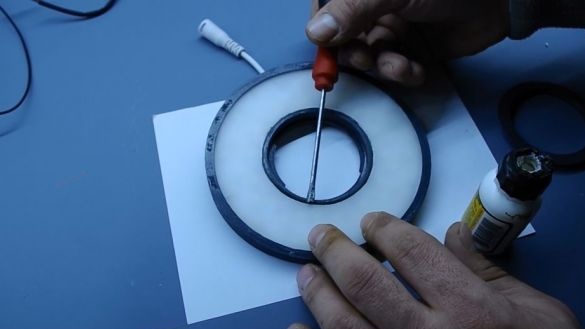

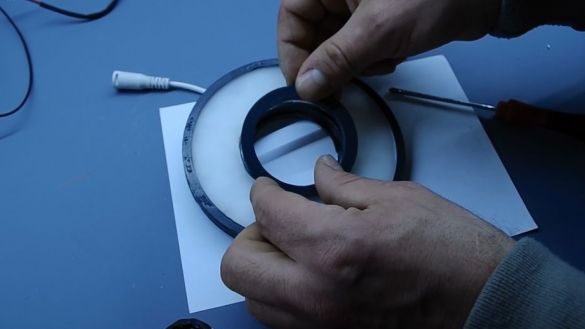

Step Four: Reflector

The reflector cuts out of white plastic.

Pastes the reflector into the ring.

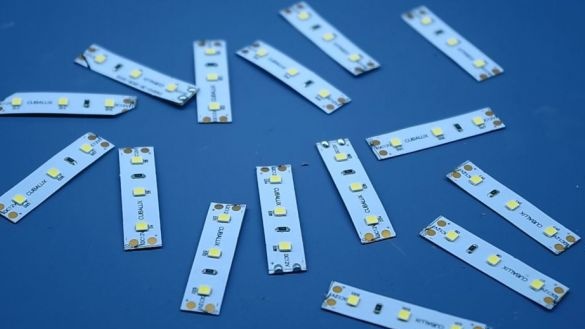

Step Five: LEDs

For lighting, the master uses a tape with white cool LEDs. Slices strips, as in the photo. Cuts off corners.

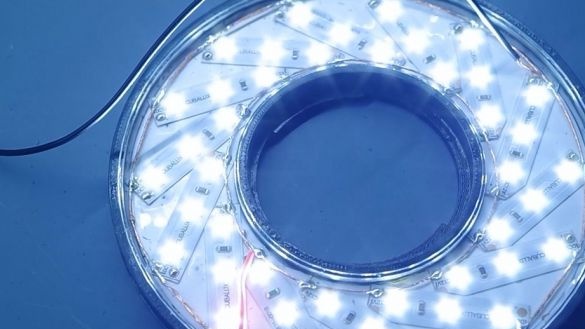

Sticks LED strip on reflector.

Connects LED strip with wire.

Checks.

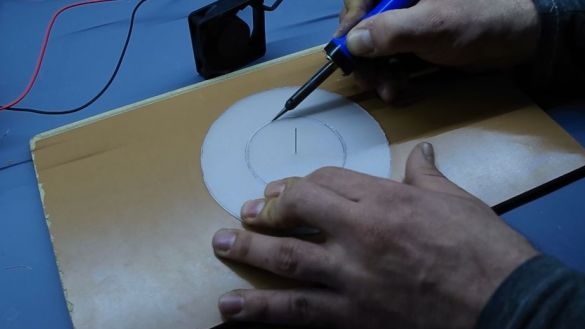

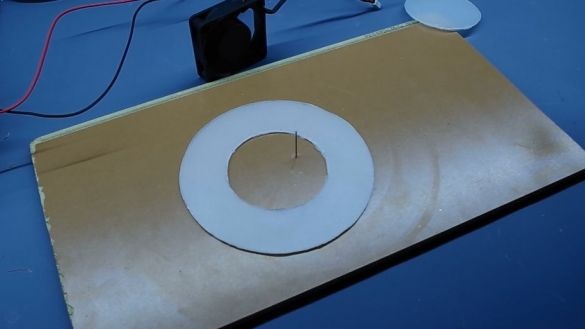

Step Six: Diffuser

The master diffuser also makes of white translucent plastic.

Cuts to size.

Before gluing, solder the cable with the connector.

Glues the ring to the diffuser, and then glues it to the body.

All is ready.

Two photos taken by a master. Left without lighting, right using ring lighting.

The whole process of manufacturing LED lighting can be seen in the video.