Greetings to fans of unusual equipment. I present to you the simplest design of an air-powered bike. Of course, such a design cannot be taken seriously, it is only a prototype that demonstrates the operability of such a device. Was previously posted bike with 4 engines in this homemade Only one powerful motor is used. And if you install two of these, the power should be enough for driving, however, the efficiency of this design is low in comparison with the classic mechanical version.

The author used the well-known motor of the 775 model as an engine. This engine has a power of 150 watts and can operate on 12-24V. Such engines are quite powerful and tenacious thanks to the forced ventilation system. In the best version of the motors, ball bearings are used instead of bushings; these models have a longer service life. Typically, these motors are used to make home-made machines, the author found for him an extremely unusual purpose. So, we will consider in more detail how to assemble such a homemade product.

Materials and tools used by the author:

Material List:

- engine 755 (you can buy a bracket for it);

- a piece of bar for the frame;

- sheet metal and nails (for a collar);

- sheet metal and a piece of board (to make a propeller);

- batteries;

- wires;

- screws;

- electrical tape;

- a control knob or just a switch;

- ropes, wire, polystyrene foam, newspapers (for fastening the structure).

Tool List:

- a hacksaw;

- hammer;

- soldering iron;

- nippers.

Homemade manufacturing process:

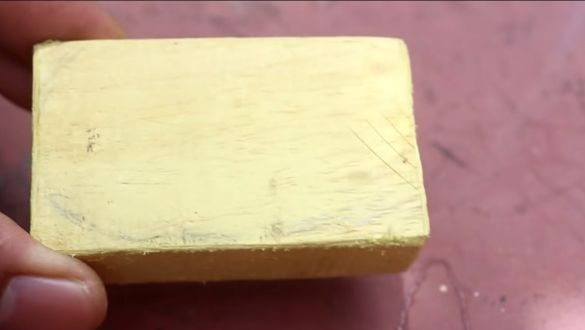

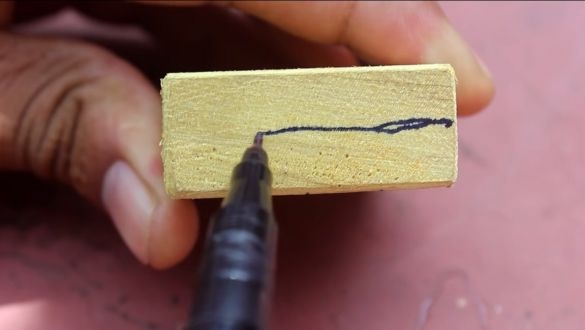

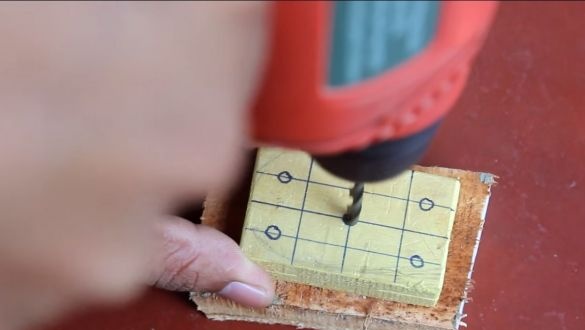

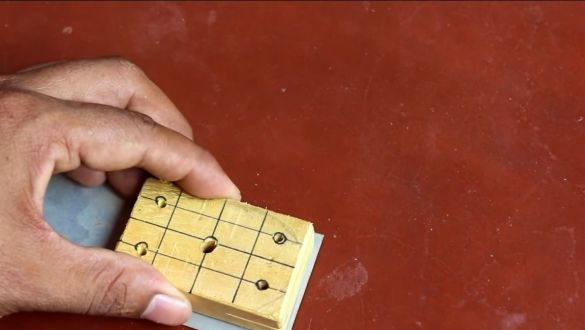

Step one. Air propeller

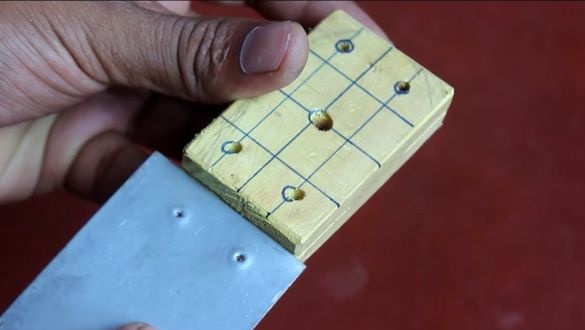

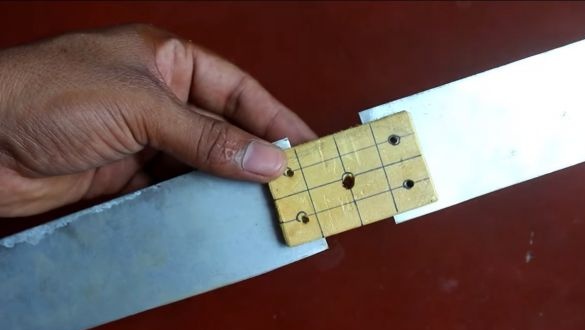

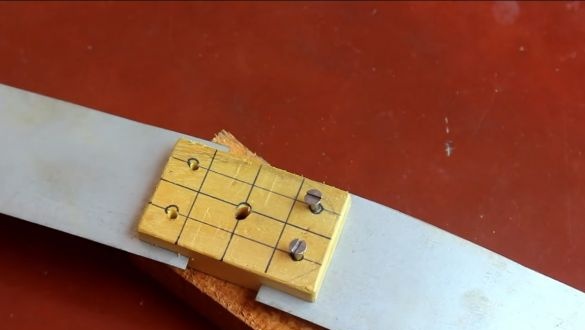

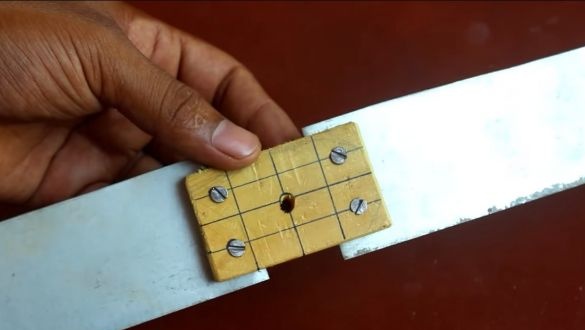

Let's start with the propeller. We take a piece of the board and do the markup. This will be the base in which the blades will be fixed. Under the blades we make slotted holes with a hacksaw. We also drill five holes, the central one will be needed to install the propeller on the motor shaft, and the rest for mounting the blades.

Well, then we prepare the blades.Their author made of sheet metal. It is advisable to choose metal more tightly to set the desired profile for the sheets. In sheets, the author punches holes with a nail. And then the blades are fixed with self-tapping screws, which the author hammered. And rightly so, that you can spin, you can score, why complicate life!

Step Two Installing the engine on the frame

The author used a piece of a bar as a frame for a motor. So that the engine does not fly away on business, we make a groove in the bar using a chisel. Well, now the motor can be fixed. For this, the author made a clamp from sheet metal, nailing it with nails to a bar.

Step Three Final assembly

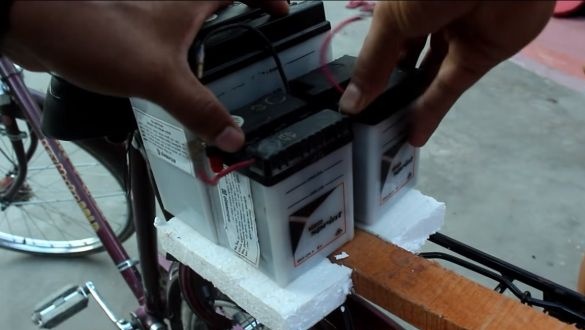

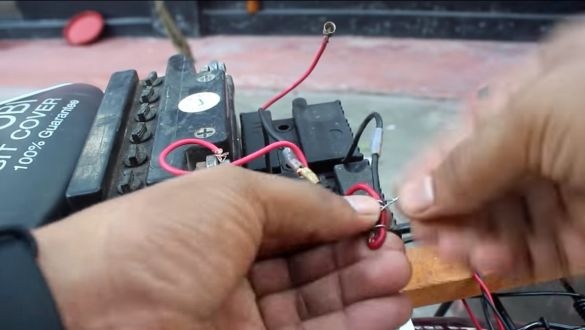

We install a block with a propeller on a bicycle, the author fastens it with the help of aluminum wire to the trunk. We also install a control handle on the steering wheel. It remains to install the batteries. For their fastening, the author puts foam and connects the wires to the terminals. For reliable fixation of batteries on the trunk we use ropes, polystyrene and newspapers! It remains to solder the wires to the motor terminals and you can take off!

Getting to the test. The author managed to get underway, though hard. If the author does not deceive us, then he passes by the camera rather quickly. One way or another, with such traction you can ride quite far along a straight road, and this is a plus. Of course, the energy consumption in this case will be large, since the efficiency of the propeller is low. That's all, the author flew away, or rather the project was completed. Good luck and creative inspiration, if this article inspired you for something. Do not forget to share your best practices and homemade products with us!