The master decided to make it himself trailer for your SUV. How he did it and what came out of it, we will consider in this article.

Tools and materials:

-Profile;

-Sheet metal;

-Roulette;

-Marker;

-Hammer;

-Welding machine;

- Jacks;

-USHM;

-Vise;

-Axle with springs and brackets;

-Wheels;

- Clamps;

-Fasteners;

-Flashlights;

Trailer device;

-Wire;

-Royal loop;

-Strip with rings;

-Wings;

-The cloth;

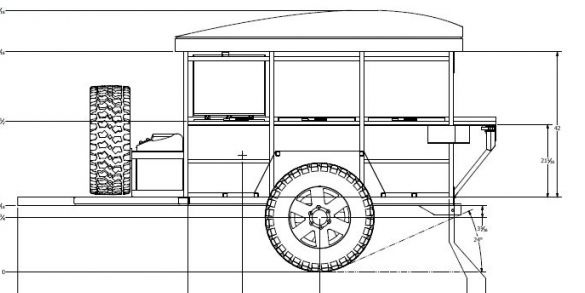

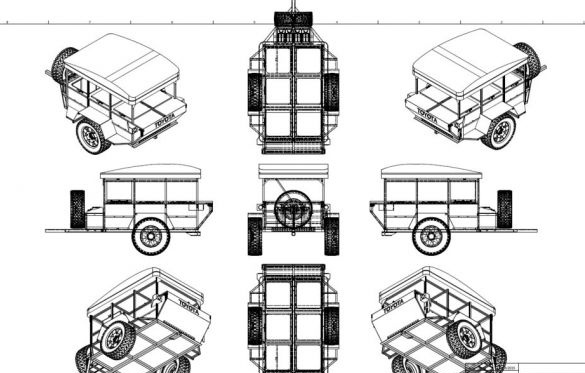

Step One: Plan

First, the master considered the option of buying a trailer. But all the trailers that he watched or did not suit him for the price or parameters. Then the master decided to make the trailer on his own. The main tasks that he set himself were the following: total length of 3.65 m; body size 120 * 180; height not higher than the car; wheels are the same as on cars; the ability to install on top of the tent.

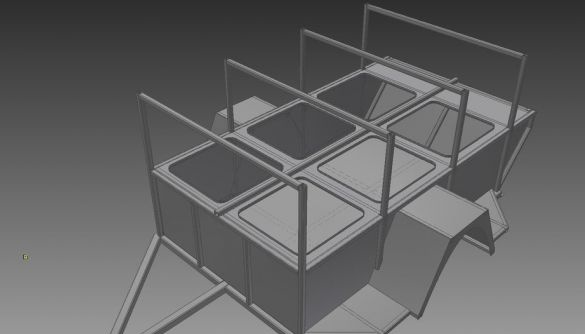

Step Two: Frame

Welds the trailer frame from the profile pipe. The central tube will also play the role of a drawbar.

For reinforcement, the kerchiefs are welded to the drawbar and reinforces the junction with a metal plate.

Step Three: Axis

Welds brackets to the frame. The springs assembly with the axle is screwed to the brackets.

Strengthens the bottom of the trailer with metal.

Step Four: Racks

Welds around the perimeter of the rack trailer.

Step Five: Drawer

Welds a box for cans.

Step Six: Sheathing and Wings

Sheathes the trailer body with metal. Welds the wings.

Seventh step: small details

Then the master completes all sorts of small details: welds the bracket for the spare wheel, bolts the mudguards, makes the installation of electrical wiring, bolts the lights. At the rear of the trailer mounts legs to prevent the trailer from tipping over in the uncoupled state. On the inside, along the sides of the body welds a profile pipe.

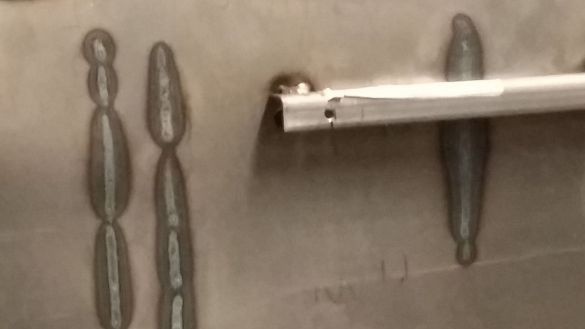

Step Eight: The Back Door

Makes the back door. The door is attached to the body with the help of a piano loop and is fixed with the help of locks-latches.

Step nine: painting and setting up the tent

The master painted in a specialized workshop with powder paint.After painting, I fixed two metal strips with rings on the floor of the body. With the help of the rings in the back, the load will be secured. At the top of the trailer secured a tent. The tent is special and has a hard floor.

The trailer for the SUV is ready.