I propose to study the instructions for the manufacture of a simple circular saw based on a small motor for 12-24V. As the power unit, the 775 engine is well suited, it and all the necessary parts can be ordered from China.

The power of such a machine is enough for cutting plywood 1 cm thick, but the machine does not cope with this task very quickly. Of course, plywood is a fairly strong material, but with the boards, fiberboard and other circular material it copes without much effort.

In addition, a drill chuck is installed on the machine. Thanks to this, various grinding wheels, cutting wheels, drills and so on can be installed on the machine. If the project interests you, I propose to familiarize yourself with it in more detail.

Design Features:

1. Work from the power source 12-24V (it is possible to feed the battery)

2. Relative safety, since the engine is used low-power

3. The presence of a drill chuck

4. The presence of a lower belt drive to increase torque

5. Metal frame - another plus for safety

Materials and tools used by the author:

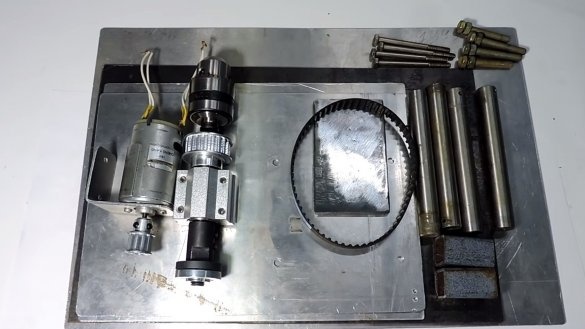

Material List:

- or similar;

- belt drive (lowering);

- ;

- bolts and nuts;

- square shaped pipes;

- Sheet steel;

- steel rods or the like for table racks;

- steel angle bracket for mounting the engine.

Tool List:

- drill;

- vise;

- grinder;

- spanners.

Manufacturing process homemade:

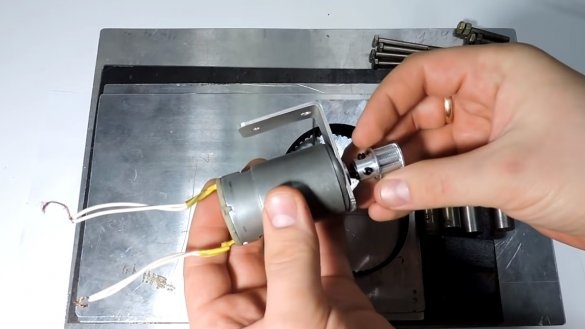

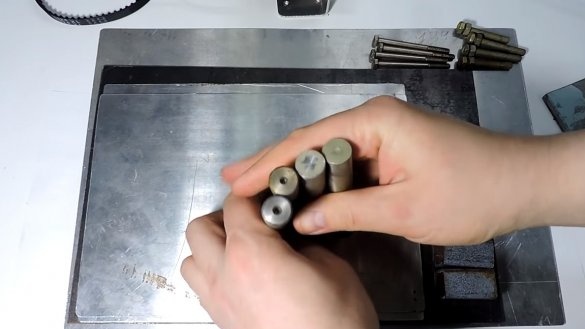

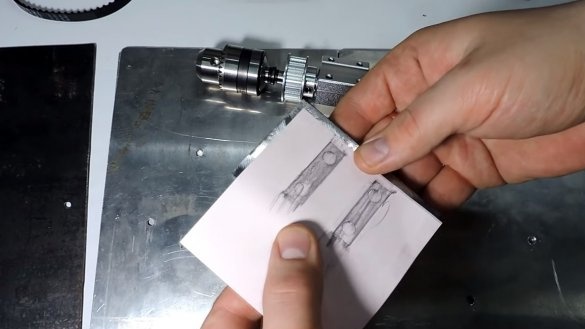

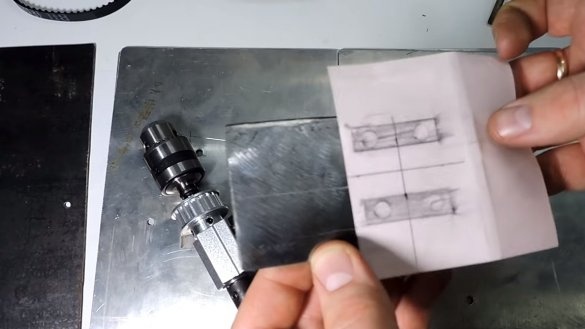

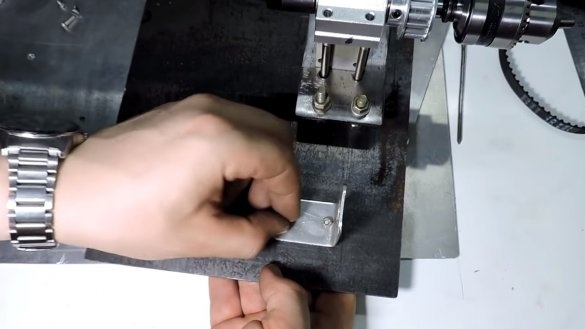

Step one. Work unit

The main working unit is a finished axis on bearings, on which a drill chuck is installed, as well as a spindle for installing nozzles for the grinder. The axis must be raised above the base, for this we need bolts of suitable length, nuts, two pieces of a square pipe, as well as sheet steel. How this whole structure is assembled can be seen in the photo.

Step Two Racks

Racks are screwed to the base, and a work table is already attached to the racks. As racks you will need steel rods or something like that. We drill holes in them and cut the thread for fastening the racks with screws.

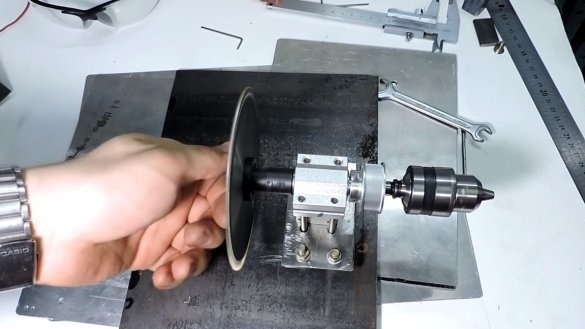

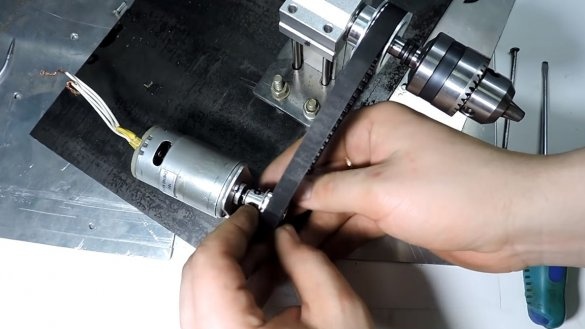

Step ThreeInstalling the axis and engine on the base

We set the axis on the base, which is a sheet of steel. Well fasten the structure with bolts and nuts.

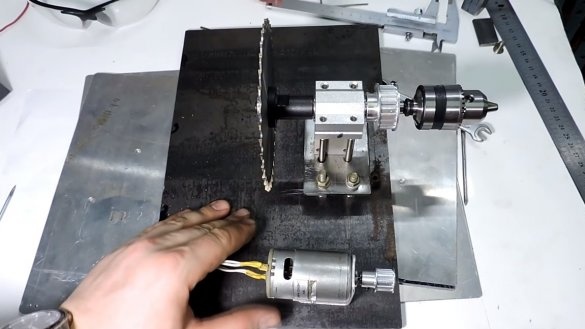

We also install the engine, use the bracket, for its manufacture you will need a corner, but you can buy one already ready. It is important to understand that we will have to move the engine on the basis so that we can tighten the belt. To do this, you will need to make slotted holes in the base, not round ones.

That's all, install the engine, pull the belt and try to turn on the device. The author, as an experiment, connects a battery to the engine, the machine works quite briskly. Instead of a battery, you can also use a power supply.

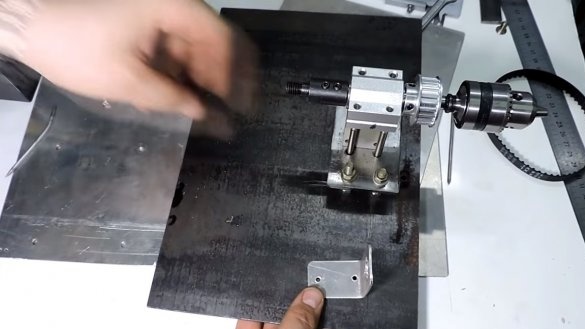

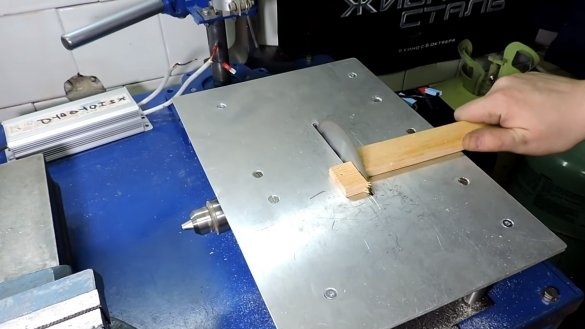

Step Four Collect the car

The machine is almost ready, it remains to assemble a table, it is twisted with screws. It is important to make sure that the rubber feet are installed on the basis of the machine, this will reduce vibration and prevent the machine from traveling around the table.

That's all, the homemade product is ready, you can experience it. The circular machine easily copes with the tasks. Using it, you can quickly and safely cut various blanks for homemade products. The author also tried to install a grindstone in the cartridge. The machine pulled it without any problems, the grinder perfectly polishes the metal.

That's all, the project is over, I hope you liked the idea. Good luck if you decide to repeat. Do not forget to share your homemade products and ideas with us!