A belt sander can be easily and simply made from an engine from a washing machine. To prove this, I propose to consider this homemade. The machine is made very simply from a minimum amount of materials. Here the engine from the washing machine was used, as well as the door closer, which is used as a tensioner. Finding other parts should not be difficult.

For such a machine, a speed regulator will be necessary, because the engine develops monstrous revolutions. Also, for grinding at high speeds, all nodes must be well balanced, otherwise strong vibrations cannot be avoided. If you are interested in the project, I propose to study it in more detail.

Materials and tools used by the author:

Material List:

- the engine from the washing machine;

- ;

- bearings for the driven roller;

- bolts, nuts, washers, screws;

- chipboard;

- Sheet steel;

- profile pipes;

- tape for grinders.

Tool List:

- grinder;

- screwdriver spanners;

- clamps;

- a tool for cutting chipboard.

Machine manufacturing process:

Step one. Engine preparation

On the motor shaft, you need to order the manufacture of the drive shaft. Here you will need to turn to the turner. The product must be well balanced if you want to work at high speeds. It is at high speeds that steel is processed.

You will also need a speed control, because if you turn on the engine directly, the speed will be too high, but it all depends on the type of engine and power. As a rule, very high speeds develop brush motors.

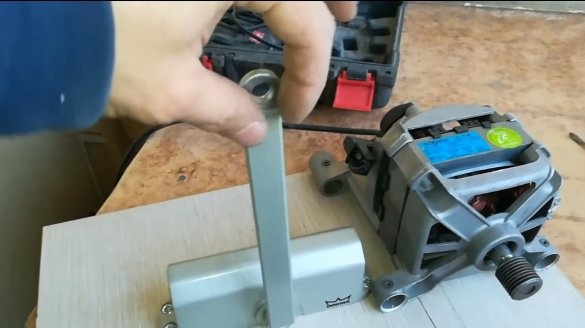

Step Two Engine installation

Next, we install the engine on the basis, for its manufacture the author used chipboard. We drill holes and fasten the engine with screws. For more reliable engine mounting, it is recommended to use bolts with nuts.

Step Three Tensioner

As a tensioner, the author used a door closer. It is simple, convenient and practical.The device can be adjusted to obtain the desired degree of tension, also the closer is easily attached to the base using all the same screws.

A driven roller is mounted on the lever, it is assembled from the bearings from the author, and a bolt with nuts acts as an axis.

After installing the tensioner, you can already install the grinding belt.

Step Four Thrust planes

In conclusion, we need to make and install thrust pads, for these purposes we need sheet steel with a thickness of at least 3 mm. We cut out the necessary pieces with a grinder and grind them on an already manufactured grinding machine.

We install supporting platforms on the machine, for these purposes there will be the necessary profile pipes, as well as bolts with nuts.

Step Five Housing

We assemble the protective case around the machine. For these purposes, you can use chipboard, plywood or something like that.

After that, the machine will be completely ready for use. We start testing, the author easily grinds a drill on it.

That’s all, the project is over, I hope the home-made interest you. Good luck and creative inspiration, if you want to repeat this. Do not forget to share with us your ideas and homemade products.