If you like tinkering do it yourself, you often miss such a thing as a pendulum saw. The device allows you to cut the material at a clearly defined angle, and cut safely. With such a tool, it will not be a problem to cut a pipe or wooden block in the manufacture of furniture and other designs where accuracy is required.

You can make such a saw with your own hands, and you can use a grinder as a basis. Of course, for the highest performance it is better to take a large grinder, here you can install a large disc for cutting wood or metal. However, all life needs are different. The machine is assembled quite simply, the frame is made of a profile pipe, and the axis on ball bearings is used as the axis. If the project interests you, I propose to familiarize yourself with it in more detail.

Materials and tools used by the author:

Material List:

- two ball bearings in the housings and an axis;

- profile pipe;

- Sheet steel;

- corner;

- bolts with nuts;

- paint for metal;

-spring;

- steel rod;

- caps for profile pipes.

Tool List:

- drilling machine;

- welding machine;

- grinder;

- marker, ruler, square;

- jigsaw;

- clamps.

Manufacturing process homemade:

Step one. Mounting bracket

First, we will make a mounting bracket, to which we will screw the grinder. Here we need three pieces of sheet steel. We will screw the grinder using the holes where the handle is wrapped. We cut three pieces and drill holes. Next, install the parts on the grinder and, making sure that everything is prepared correctly, grab the parts by welding directly on the grinder. Well, then we remove the bracket and boil well from all sides, so that everything is held securely.

Step Two Base

Next we need to assemble the base, here we need rectangular shaped pipes. Cut 4 pieces of suitable sizes and weld the frame at right angles.Here, welding magnetic squares will help us well.

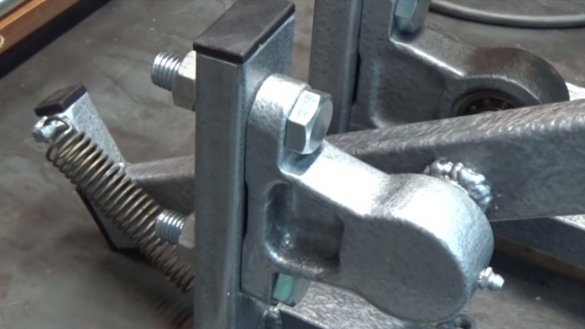

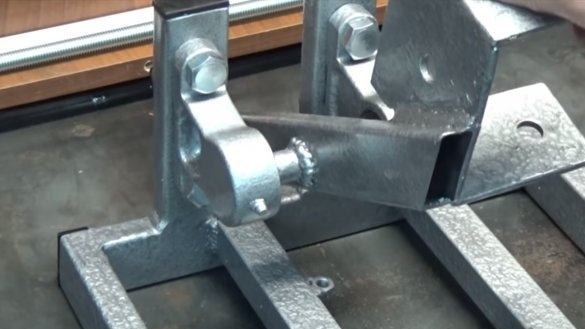

Step Three Bearing Installation

We install bearings on the frame, for this you first need to make two racks. We cut off two pieces of a rectangular profile pipe and drill holes for the bolts with which we will screw the bearing housings. The racks themselves are welded to the frame, we clean the welds so that everything looks neat.

Step Four Lever and axle

We cut a piece of the profile pipe so that a lever is obtained on which the working tool will lower and rise. We weld the axis of the bearings here, and at the end of the lever we weld the bracket to which the Bulgarian is attached. When everything is ready, the lever can already be mounted on bearings.

Step Five Emphasis and spring

There should be an emphasis on the working surface, we will rest the material on it when cutting. Of course, the angle of this emphasis should change. As an emphasis, the author used a piece of a corner, and bolts with nuts are used for fastening. Nuts are welded to the frame, with which you can fix the emphasis. The emphasis is pivotally fixed to the frame through a slit hole, which the author cut with a drill and a jigsaw.

Another lever you need to pick up a spring that will return the tool to its original position. It is possible a powerful spring is needed, but you can use two. It all depends on the weight of the tool and the length of the lever.

Step Six Painting and testing

The machine is ready, disassemble it and paint. For painting, the author used a special rust enamel, such paint lays on the metal reliably. Well, then we collect our homemade, install the grinder and test.

The author has welded a steel rod to the upper bolt, and at the other end of the rod there is a nut, into which the handle from the grinder is wrapped. The result is a very comfortable long handle, for which we will take it by hand when cutting.

The machine is ready, set the desired angle and cut the material. The machine copes with the task quickly and accurately. That's all, the project is over, I hope you liked the home-made. Machine parts are subject to repair, in the event of backlash in bearings, they can be replaced.

Good luck and creative inspiration, if you want to repeat this. Do not forget to share your ideas and homemade things with us!