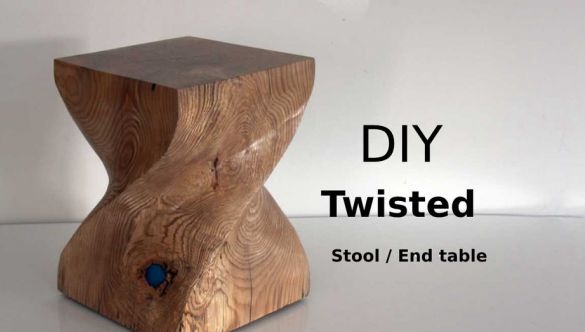

Hello. This time I suggest you work with a tree. And we will do an unusual massive stool. Its unusualness is that the stool is made of hemp, it is completely monolithic. To give the product a more interesting look, the author made it as if it was twisted. Such furniture It looks beautiful and it is almost eternal. The author used ash as wood, this wood is very strong and has a beautiful pattern. For manufacturing, you will need a rather small set of tools, and we have only one material - a stump, not including finishing materials (oil, epoxy and so on). So, we will consider in more detail how to make such a stool!

Materials and tools used by the author:

Material List:

- stump of ash;

- oil for wood;

- epoxy glue and dye;

- finished legs made of rubber or materials for their manufacture.

Tool List:

- chainsaw or electric;

- a grinder (petal nozzles, a disk on a tree with three teeth and a "flypaper" for sanding grinding);

- planing machine;

- hammer;

- measuring instrument and more.

The process of making stools:

Step one. We select the source material

As a source material, the author used ash. This wood is dense, strong and has a beautiful pattern. It is important to understand that the tree must be dry, otherwise it will still crack after applying the oil, and the oil will not be absorbed. The author has dried wood for 18 months in the open air.

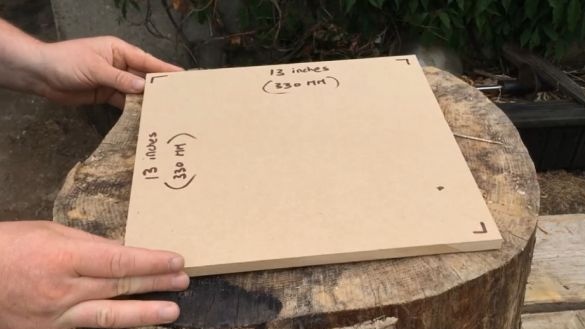

Next, we determine the size of the stool, which we can cut. The author decided to make a template from MDF, cardboard or paper is also suitable.

Step Two Start cutting

Next, we need to make a square out of hemp. Then the author decided to use a chainsaw, this can be done manually, but it will take a lot of time and effort. When everything is done, we go through the planes with a planing machine to remove rough irregularities.

Step Three Cut the "screw" part

Next, we need a pencil and a ruler. We mark on the material where you need to cut off the excess to get the effect of a swirling tree. Well, then you can start cutting. The author again performed the main work with a chainsaw. The main thing here is not to rush and cut off the excess, otherwise you can ruin everything.

Step Four We cut the grinder

Then we can proceed to finer processing, here we need a grinder. With it, we will form the main profile of the stool.For work, the author used a metal disk with three teeth for cutting wood. It is safe when compared with circular disks, which many install on grinders. Carefully remove excess material from the marked area. How to do this, everyone decides for himself, this is a creative process. We create a profile to your taste. As a result, an almost finished product is obtained, and you can proceed to grinding.

Step Five Coarse grinding

You can begin rough grinding to remove all the defects that remain from cutting. Here we need a petal nozzle for the grinder. Granularity will need a large one, since it will be necessary to remove the tubercles, smooth the grooves, and so on.

Step Six We work with epoxy

Next, we arm ourselves with epoxy and proceed to eliminate the defects. With it, you can fill in cracks, holes, strengthen rotten areas and so on. You can show imagination and add any dye to your epoxy at your discretion. Keep in mind that the resin can be quite fluid, and this will be absorbed into the tree. But if you use a quick-drying epoxy, you may not have time to drive out air bubbles from it. In order for the air to escape, the epoxy after pouring can be heated with a hairdryer.

After all this, leave the epoxy to dry, we will need to grind it later.

Seventh step Finishing

When the epoxy is completely dry, bouts to grinding the entire product. Here we need a grinder with disc nozzles made of sandpaper. The author used sandpaper with a grain size of 120 units. In general, the finer the abrasive at the final stage of processing, the more beautiful the product will be and the less oil will be needed for coating.

Step Eight. Coat with oil or varnish

In general, ideally, the tree is covered with oil, this is the best coating. Oil well emphasizes the natural appearance of wood, and also protects it well from moisture. But the author decided to use water-based varnish, because he did not have the patience to wait until the oil dries. For the best effect, you need to apply several layers and before each new layer to perform easy grinding.

Step Nine. Legs

So that the stool does not spoil the floor and does not stagger on an uneven surface, make legs for it. The author set four rubber feet on the base. They are fastened with studs.

That's all, after that our stool will be ready. It looks pretty beautiful, unique. This is a clear example of what a masterpiece a hemp can make. That's all, good luck and creative inspiration, if you decide to repeat this. Do not forget to share your homemade with us.