For his workshop, the Master made an unusual chair. The chair on the long lever rotates in different directions, and without getting up from it, you can get to various tools installed in the workshop. Also, the chair seat can be raised to different heights. Another function of the chair is its transformation into a support for long workpieces, for their further processing.

Tools and materials:

-Metal pipe;

-Welding machine;

-Threaded rod;

Trapezoidal nut;

-Vise;

-Metal strip;

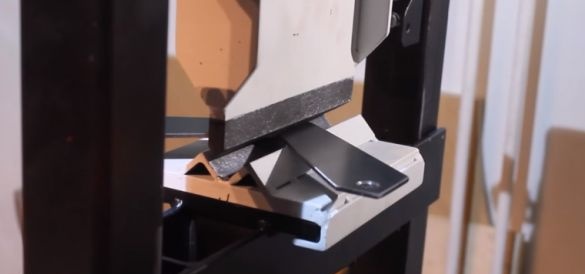

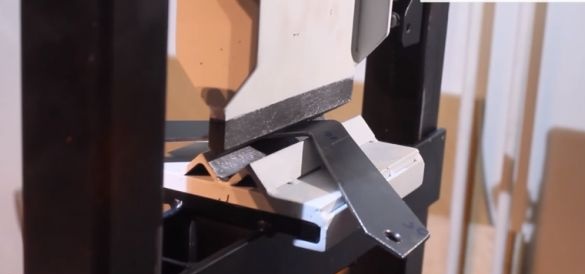

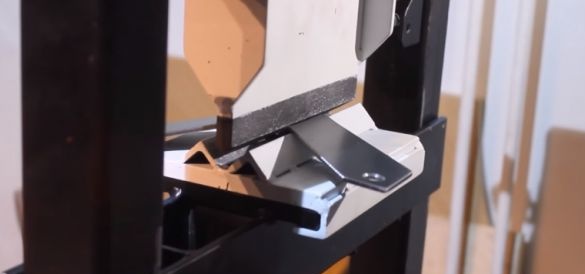

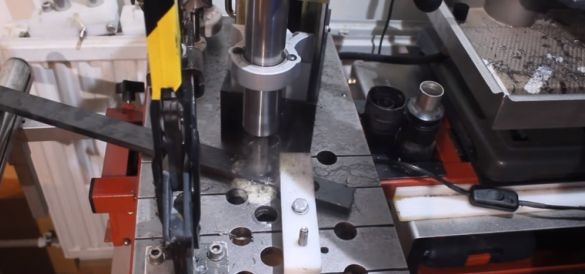

-Press;

-Drilling machine;

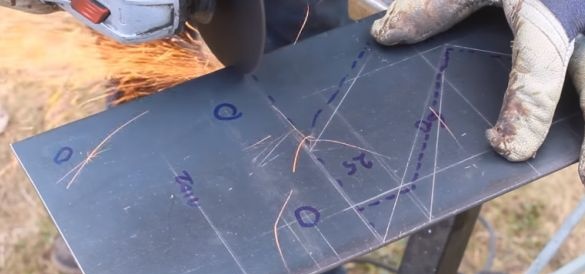

-USHM;

-Dremel;

-Metal corner;

-Metal rod;

-Sheet metal;

-Electric jigsaw;

-Board;

-Tape grinding machine;

-Linseed oil;

-Fasteners;

-A screwdriver;

Step One: Nut

A trapezoidal nut is welded to one end of the metal tube. This will be the support nut for the seat screw.

Step Two: Material Procurement

Next, the master prepares the material for further installation. He takes two thick metal strips and bends their ends a little. Moreover, the opposite ends are bent in opposite directions. Drills holes on one side of the workpieces, grinds the other side in a semicircle.

Makes a perforated plate.

Makes a mounting bracket.

Makes seat mounting plates.

Drills a corner, cuts it into two parts.

Makes eyelets, kerchiefs and deadbolts.

Step Three: Frame Assembly

Fixes the corners on the board and mounts the frame. The seat will be mounted on the frame.

Step Four: Lever

Welds the lever.

A tube with a trapezoidal nut and a threaded rod is welded to the lever. A frame is welded to the top of the screw.

Step Five: Seat

From a board cuts out a seat. Grinds the surface. Applies linseed oil. Screws to the frame.

Step Six: Installing the Seat

Fixes a corner on the table leg. Sets the lever. Screws in the seat.

All is ready. In the photo below you can see an example of the seat.

You can watch the manufacturing process on video.